By Carl Babcoke, CET

These reports describe an industrial type of component, control system, or specialized testing equipment. Some information was obtained from the manufacturer's instruction book and specifications sheet. The comments are based on personal inspection and operation of the device. Suggestions are given for both typical and unusual applications.

Infrared photoelectric control Autotron model RPF-303 photo electric control system performs on/off switching of controlled equipment power according to whether or not the light beam is unbroken between transmitter and receiver.

Infrared light cannot be seen by unaided human eyes, so it is the choice when the light beam must be invisible. It also reduces problems from indoor ambient lighting, since fluorescent and incandescent bulbs do not radiate much infrared.

Additional immunity from ambient lighting is provided by modulating (chopping) the light source and limiting the receiver response to rapidly varying light levels only. Therefore, the receiver ignores all steady or slowly varying light levels.

For maximum immunity to ambient lighting, model RPF-303 operates with a chopped infrared light beam.

Reflected light--For most applications, the light beam is emitted and received through the same lens.

This requires some kind of reflector at the far end to bounce the light back along the same route.

A retro-reflective disc has many 6-sided optical cells that reflect their outgoing beams closely parallel to the incoming beam. With retro-reflective paint, chalk and plastic tapes, the reflecting elements are a multitude of tiny transparent spheres. These materials reflect the light satisfactorily, even when the reflector is being vibrated or the disc is not tilted perfectly.

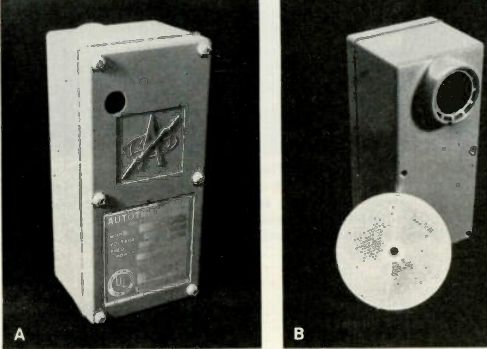

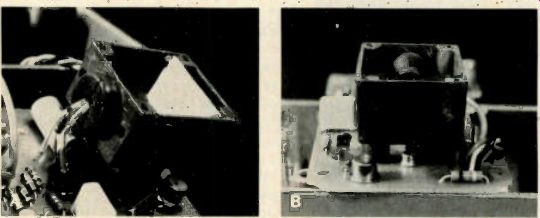

-------------- Autotron photoelectric system model RPF-303 is self-contained,

except for the reflector. (A) The focusing lens for outgoing and incoming

infrared beams is on the front of the metal enclosure which contains the electronics.

Also shown is the retro-reflective disc that bounces the beam back to the

lens. (B) The removable back has model number and electrical ratings. At the

upper-left corner Is the filter that covers a red LED used to indicate relative

beam strength during alignment of the light path.

Many useful functions can be done when the alignment of light beams with the objects being monitored has been properly performed.

For example, the position of reflective tape on a carton can activate a mechanism that diverts the carton to the desired moving belt.

Basic description

Model RPF-303 has a die-cast aluminum box with dimensions of approximately 6 3/4- x 3 1/8- x 2 5/8-inches plus a 5/8-inch protrusion that protects the glass lens on the front. The removable back cover is secured by six captive screws, and a lip between box and cover prevents blow-in or deformation of the sealing gasket during high-pressure cleaning.

Six tapped holes in the bottom and four in the front of the case allow various kinds of mounting. A large 5/8-inch tapped hole is provided in the bottom for electric wiring. If the conduit is thick-wall type, the unit could be mounted by this wiring hole. A swivel bracket for tilting the unit to almost any angle is optional.

One 3-inch reflector disc is included with the basic unit. The disc can be mounted in many different ways.

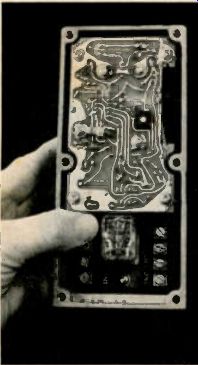

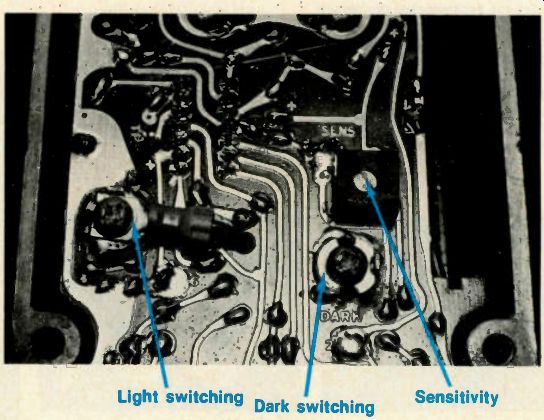

----------- Removing the back exposes the circuit board's wiring side.

Below the board are the ac wiring terminals and the plug-in power relay. The

notch in the board is for insertion of any optional timing module. Without

a module, the unit performs on/off switching in synchronism with breaking

and closing of the beam.

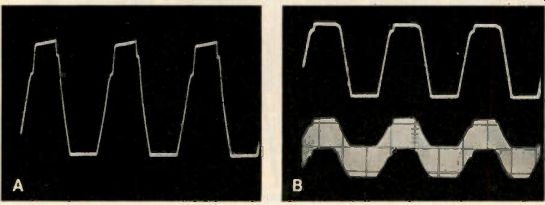

------------ (A) These 0.5VPP 5000Hz almost-square waves were scoped across

the infrared transmitter LED. Notches near the top mark the start and finish

of LED current. (B) Similar waveforms were found at both base and emitter

of the driver transistor (top trace). The collector waveform (lower trace) showed

a large amplitude of 120Hz power-supply ripple when scoped to ground. On the

sample, base measured + 3.63V, emitter +3.01V, and collector +14.21V.

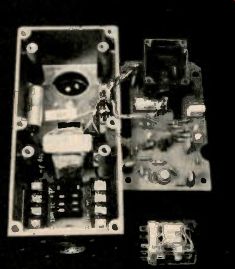

Removal

of four screws allows the circuit board to be removed and turned over for

good accessibility. Power-supply components and the module socket are exposed.

Electronic operation

An IC oscillator generates square waves which are amplified by one transistor. The transistor collector current lights a GaAs infrared LED. This is the transmitter signal.

Light from the LED travels straight through the 45° mounted half-silvered mirror, and is focused into a beam by passing through the glass lens on its way to the reflective disc. The disc reflects the beam back through the same lens.

However, the angle-mounted mirror diverts the beam, causing it to strike the phototransistor. Output of the phototransistor has a dc level from the ambient lighting and square waves from the light beam.

The dc is removed by high-pass filters, while the square waves are amplified and rectified to become a dc signal voltage that varies with the strength of the chopped infrared signal.

A sample of the rectified dc voltage controls the brightness of a red LED that can be seen through a red filter on the back of the housing. Stronger signals increase the red LED brightness. This varying brightness is used as an indication of relative signal strength during adjustments of the reflector (for maximum signal level). Another sample of the dc signal operates a Schmitt trigger which provides dependable snap action of the relay-driver transistor and ac power relay.

A wire with spade lug is connected to either the screw terminal marked light or the one marked dark. This determines whether the relay is energized when the beam is unimpeded (light) or when the beam is blocked (dark). Sensitivity can be adjusted by rotation of the sens control.

The power relay has double-pole double-throw contacts rated at 10A for a resistive load. The relay plugs into a socket for easy replacement, and it is sealed to keep out dirt and moisture. Terminals are provided near the relay for line voltage and relay wiring.

Timing modules

As it comes from the factory, the RPF-303 performs dependable on/ off operations. However, a slot at the right of the sensitivity control allows installation of a function card (module or panel) in the edge-connector socket.

These function cards permit the timing of either light or dark cycles.

They have variable time-delay controls.

Other options include these:

• Solid-state switch (opto-isolated triac) output that gives longer life and handles faster repetition rates.

• Logic output that is supplied by a transistor sinking up to 100mA. This allows interface with electronic controllers and computers.

• A visible red LED light source for easier testing and alignment of the beam in difficult installations.

• Inputs for 230Vac, 12Vdc, or 12Vac power. The unit draws only 5W.

• Universal swivel mounting bracket.

• A separate transmitter unit for operation up to 200-feet. Standard dual-purpose units operate with up to 35-feet of beam distance. Of course, smoke, steam or dirty windows in the beam path reduce the maximum distance for depend able operation.

• A special system is available with a 6-digit manual-reset counter mounted on the housing.

Applications

Counting operations, end of roll indicator, blockage indicator, one shot action (filling pie shells, for example), and burglar alarm are a few applications. Autotron literature illustrates many uses.

The RPF-303 manual devotes one full page to servicing these units.

Many typical possible problems and remedies are illustrated. Most components are readily accessible.

Technicians who are experienced with solid-state analysis on circuit boards should have no unusual difficulties when servicing these control systems.

------ Photo (A) shows the phototransistor end of the beam-splitting mirror.

(B) The infrared LED is on the chassis below the mirror assembly.

--------- Arrows point to the light terminal with wire (this causes the

relay to close and remain closed while the beam path is complete), the dark

terminal (when the wire is moved to it, the relay closes and remains closed

so long as the beam path is open), and the sensitivity control. These are

the only adjustments, although each plug-in timer module has a time control.

Also see: