AMAZON multi-meters discounts AMAZON oscilloscope discounts

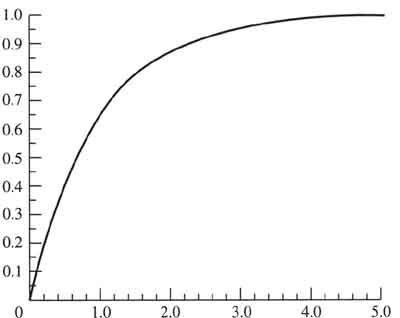

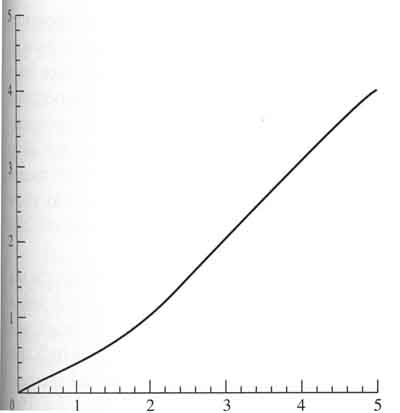

The manner in which a process control system responds is very important. It is necessary to understand the types of response so that you can adjust the controller. The system response types include: under-damped, critically damped, and over-damped. ill. 1, ill. 2, and ill. 3 (all below) show examples of these responses. The graphs display time (t) along the x-axis (left to right) and amount of PV along the y-axis (top to bottom). If the PV is above the SP (recall, SP is set point, and PV is process variable), it’s called overshoot, and if it’s below the SP, it’s called undershoot.

The normalized response is a medium-speed response, which doesn’t allow the PV to overshoot. This is also called a first-order response. An example of its use is in heating a product like the tomato sauce used to make salsa. If the tomato sauce is overheated, it will burn and the salsa will lose its taste. Overheating the product will also affect shelf life, which means the salsa will lose its taste quickly while waiting to be sold.

The under-damped response is a little faster responding, and it allows the PV to oscillate slightly around the SP. Since the controller reduces the amount of overshoot and undershoot in four amplitudes, this type of response is called quarter amplitude decay (QAD). This type of response is used to maintain the level in a filling bowl for a system where beverage cans are filled on an automated line. The response will occur when the level in the filler bowl gets low and fresh beverage is added to the bowl. The response to the low level needs to be fairly fast, and the system is not harmed if the level oscillates (QAD) around the SP as the bowl is being filled.

Above: ill. 1. Graph showing an under-damped system response.

The over-damped (ill. 3) response is a very slow response that's used when bringing systems up to temperature. E.g., when a process cooker is first brought up to heat, it must be heated slowly so that it does not crack. The heat for the cooker comes from steam. The steam valve is controlled with an over-damped response so it opens slowly and allows the temperature to increase slowly. It may take over an hour to bring the temperature from room temperature to 200°F.

Loops that respond quickly are called critically damped loops (ill.

2) . An example of this type of response would be a steam heating coil

for a jacket-type product

heater. The jacket allows steam to circulate around a kettle and heat

the product without touching it. Any time the steam valve is opened

or closed slightly, the temperature will change quickly.

Above: ill. 2. Graph showing critically-damped system response.

Above: ill. 3. Graph showing over-damped system response.

PREV: Example:

Ratio Control For On/Off Heating Contactor

NEXT:

Tuning the Controller