AMAZON multi-meters discounts AMAZON oscilloscope discounts

The isolation, in structures, of those vibrations or motions that are classified as mechanical vibration. Vibration isolation involves the control of the supporting structure, the placement and arrangement of isolators, and control of the internal construction of the equipment to be protected.

The simplest kind of mechanical vibration has the waveform of sinusoidal motion. Vibrations in structures, although generally more complex in waveform, exist wherever movement takes place. Such movement may be caused, for example, by the engine in an automobile, by engines or wind buffeting in aircraft, or by a punch press in a building. Delicate electronic equipment and precision instruments must normally be isolated from these motions if accurate measurements are to be obtained.

Vibration, in most cases, may be effectively isolated by placing a resilient medium, or vibration isolator, between the source of vibration and its surrounding area to reduce the magnitude of the force transmitted from a structure to its support or, alternatively, to reduce the magnitude of motion transmitted from a vibrating support to the structure. Isolating vibration at its source is commonly termed active or source isolation; isolating an instrument from its surroundings is known as passive isolation.

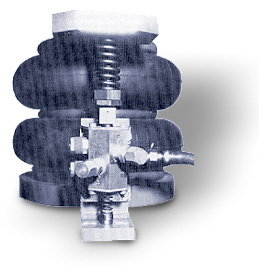

Above: This mount assembly from MRAD,

utilizes a unique configuration of U-shaped springs to obtain stiffness

characteristics. System damping is provided by integral friction or viscous

dampers, which are consistent over a wide temperature range.

The vibration isolators may be positioned and arranged in many different ways, all variations of three basic types, each of which requires a definite amount of space: (1) isolators attached underneath equipment, known as an underneath mounting system: (2) isolators located in the plane of the center of gravity of the equipment, known as a center-of-gravity system; (3) mountings arranged four on each side in the plane of the radius of gyration, known as a double side-mounted system or radius-of-gyration system.

Above: An "Air Springs" isolator from MRAD,

It operates from a continuous supply of compressed air or other inert

gas to provide isolation of mounted equipment from vibration and shock, and to provide continuous automatic leveling by means of pneumatic support

elements control led by height sensing servo-valves.