AMAZON multi-meters discounts AMAZON oscilloscope discounts

1. INTRODUCTION

Electrostatic discharge (ESD) is a phenomenon in which static electric charges accumulated on one object suddenly discharge to another object having a lower resistance to ground. The ZEEE Guide [1] defines ESD as the sudden transfer of charge between bodies of different electrostatic potentials. The transfer of charge with resultant discharge currents generates electromagnetic fields over a broad range of frequencies from dc to low gigahertz [1]. The semiconductor integrated circuits and components are especially susceptible to the effects of uncontrolled ESD events in their vicinity. They can affect the performance of an electric device in a variety of ways: by intense electromagnetic fields due to the charge, by breakdown and its associated effects, and by the discharge currents causing conducted and radiated emissions. An ESD event can cause equipment malfunctions in the form of data corruption and equipment lockup, and physical damage in the form of equipment damage and even loss of life.

It’s therefore important to provide, during the design phase, meaningful ESD immunity to a device by taking into account the discharge and associated field configurations that will be encountered by the entire system during its expected lifetime. Various aspects of ESD are described in [1-9]. In the present section we describe briefly the ESD phenomenon, its possible effects on an electric device, and the types of interference it may cause. Our discussion is mainly based on the ZEEE Guide [1] and on [2,3]; more detailed discussion of ESD can be found in the other references cited.

2. ACCUMULATION OF STATIC CHARGE ON BODIES

There are a number of ways that a body or bodies can be electrostatically charged where the charging is defined as all processes that produce a separation of positive or negative electric charges on the body under consideration. The main processes relevant to ESD are the following:

Triboelectric Charging. Static electricity is generated by contact and/or rubbing of two materials of different dielectric constant. This charging mechanism is referred to as triboelectric charging and involves electron or ion transfer upon contact. During the process some materials readily absorb electrons and thereby acquire negative charge while others tend to give up electrons and thereby acquire positive charge. TBL. 1 presents the triboelectric series, a listing of materials in the order of their affinity for giving up electrons.

Note the positive and negative connotations at the top and bottom of the table; this means that when two materials of the table are in contact, the one closer to the beginning of the series will acquire positive charge, while the one closer to the end of the series will acquire negative charge. The farther apart the materials are in the series, the greater the magnitude of the static charge that will develop. For example, rubbing nylon against Teflon can cause electrons to be transferred from the nylon surface to the Teflon surface. As a result nylon may acquire positive charge and Teflon may acquire negative charge. The electrostatic charge that can be developed between two materials depends on their relative position in the triboelectric series, and also in their surface (or volume), respectively. Materials higher in the series can accumulate significant charge because a longer time is required for the charge to decay in such materials (note: decay or relaxation time T in a material is T = c/o = cp, where p is the resistivity of the material). Under certain instances even conductive materials such as metals can be charged, as shown in TBL. 1. The order of ranking in a triboelectric series is not fixed, and moreover it’s not always possible to duplicate the series.

Also, the magnitude of the charge transfer depends on a number of factors in addition to the material's position in the series: For example, the smoothness of its surface, surface cleanliness, the pressure of contact, and the speed of separation.

Charging by Induction

Induction or electrostatic induction (an IEEE term) may cause portions of the human body or other items to be differentially charged. If a charged object (e.g., the face of a cathode ray tube) is brought near another object, it will polarize the charges on the object if it’s nonconducting (an insulator) or redistribute the charges on the object if it’s conductive. Thus, although the object may remain electrically neutral, its charges may be distributed unequally, thereby creating the possibility of ESD from a portion of the person or the body [1]

======

TBL. 1 Triboelectric Series.

POSITIVE Air Human skin Asbestos Glass Mica Human hair Nylon Wool Fur Lead Silk Aluminum Paper Cotton Wood Steel Sealing wax

Hard rubber Mylar Epoxy glass Nicked, copper Brass, silver Gold, platinum Polystyrene foam Acrylic Polyester Celluloid Orlon Polymer transform Polyethylene Polypropylene PYC (vinyl)

Silicon Teflon NEGATIVE

======

3. CHARGING AND CHARGE SEPARATION

We saw earlier that contact between two materials causes transfer of charge.

Because the materials are physically separated, the resultant charge separation creates an electric field E between them. If this E field is sufficiently strong, a voltage breakdown between the objects may occur; this may result in a breakdown of the intervening medium, causing an arc and its associated electromagnetic effects. Consider a simple case where a transfer of charges +Q and -Q has taken place between two bodies. The relationship between the charge amplitude and the voltage between the objects is V = Q/C, where C is the capacitance of the system. Observe that as the two bodies are separated the charge Q remains fixed, Q == VC = constant. We know that C a l/d, where d is the separation distance between the bodies. Thus for small distances C is large but V is small, as indicated by (10.2). As the objects are separated farther, C decreases; V must therefore increase to keep Q constant.

Example 1

Let C = 10 pF, Q = 1pC, V = Q/C = 109 KV for a certain value of d. It’s possible that at a certain separation distance the intervening air medium may break down. Note that the breakdown field strength for air is 30 MV/m or 30 KV/cm. Note also that the energy stored in a charged system like the human body or any other object is a function of the capacitance and its voltage, and is given by W = iCX2, where C is the capacitance in farads, V is voltage in volts, and W is energy in joules. For example, a person walks across a carpet and becomes charged to 10 KV. Assuming a body capacitance of 100 pF, we determine the stored energy as ...

The charging and separation of accumulated charges and their associated effects are simple to understand when the two objects are insulators. They also would occur when an insulator is separated from a conductor. The degree of charge separation is less than that for two insulators because as the conductor is separated from the insulator the charge tends to redistribute itself over the conductor in relation to the relaxation time c/o mentioned earlier. Observe also that static charges are stored on the surface of a conducting material; with an insulator the charges tend to remain in the vicinity of the attachment point, whereas for a conducting material the charges tend to redistribute over the surface. Grounding a conductor will bleed off the charge, but grounding an insulator will not. A charged insulating body alone may not pose a problem because the charges on it are not free to move and hence it cannot produce a static discharge. However, a charged insulator can induce charge on a conductor in its vicinity; thus there may be electrostatic discharge associated.

Generally, the ESD is a three-step process: charge is generated on an insulator, the charge is then transferred to a conductor, and the charged conductor comes near a metal object, usually grounded, and a discharge takes place.

Common examples of charging processes are given in... Cathode ray tubes used as display devices and sometimes as input devices for computer terminals, oscilloscopes, and television sets can be sources of charges. Humans are a prime source of electrostatic discharge carrying harmful effects to electronics devices. The next section discusses the human body from this viewpoint.

4. HUMAN BODY AS SOURCE OF ESD

Electrostatic charge accumulation takes place as a result of triboelectric effects when a human wearing shoes with soles made of insulating materials (e.g., polyurethane foam) walks on low conductivity materials such as wood or the synthetic materials in carpets [1,2]. The charged shoe soles cause charge redistribution on the human body by induction. As each step is taken, this charge redistribution increases [1] The maximum total electrostatic charge that can accumulate is of the order of 10@ coulombs or more, depending on the nature of the carpet and the shoes, the humidity, the distance the person has walked on the carpet, and other factors. This could result in a voltage up to 15 KV. To describe ESD characteristics and variables, we follow the ZEEE Guide [1]and schematically illustrate the direct ESD event as in FIG. 1.

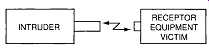

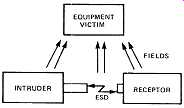

FIG. 1 Direct ESD event.

The intruder is frequently a human hand with or without an associated metal object, but it may be an object such as a chair or equipment cart. The receptor is the stationary object to which the charges are transferred by the intruder where the receptor may be at local electrostatic ground potential. The equipment victim is an electronic device that is often the receptor, but it may also be the intruder or an object that is neither the intruder nor the receptor.

In this last case the equipment victim is in close proximity to the ESD event and may be upset or damaged by the electromagnetic fields generated by the discharge between the intruder and the receptor. When either the intruder or the receptor is an equipment victim, the ESD is termed direct. When the equipment victim is neither the intruder nor the receptor, the ESD is termed indirect.

Examples of direct ESD events of various kinds are shown in FIG. 2 through 8 taken from [1] The intruder may be human ( FIG. 2 and 4), an inanimate object ( FIG. 5; 8), or a combination of the two ( FIG. 3, 6, 7). TBL. 2 lists the various kinds of intruders with the names of the ESD events that result from each.

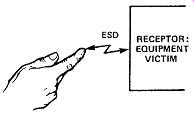

FIG. 2 Direct body/finger ESD.)

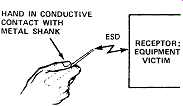

FIG. 3 Direct hand/metal ESD or body/metal ESD.

FIG. 4 Direct brush-by ESD.

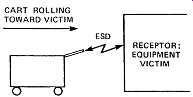

FIG. 5

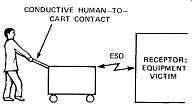

FIG. 6 Direct furniture ESD-Rolling cart with human.

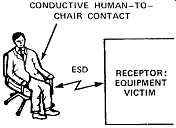

FIG. 7 Direct furniture ESD-Rolling chair with human.

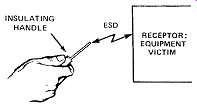

FIG. 8 Direct furniture ESD-Screwdriver alone. INSULATING HANDLE RECEPTOR:

EQUIPMENT, VICTIM

FIG. 9 Indirect ESD event. EQUIPMENT; VICTIM FIELDS

====

TBL. 2 ESD Intruders and Resulting ESD

ESD Intruder 1 .Type of Resulting ESD

Human object Metal object Human/metal object Body/Finger-from finger without associated metal object Brush-by-from hip, torso, or shoulder Hand-associated-tool or other object not in conductive contact with the hand or body Furniture-not in conductive contact with the hand or body Body/metal or hand/metal-tool, ring, watch, or other metal object in conductive contact with the hands or body Furniture and human-in conductive contact with the hand or body; human seated in chair, pushing cart, or vacuum cleaner; holding and in conductive contact with a tool, etc.

====

In the case of a human intruder, the ESD may be a body/finger ESD that originates directly from the skin ( FIG. 2). It may also be a brush-by that originates from the body ( FIG. 3). In the case of a human contact with a small metallic object, a body/metal or hand/metal ESD is one that originates from a metallic object associated with a hand such as a ring, watch, screwdriver, or key as in FIG. 4. If the human is not in conductive contact with the small metallic object, the source of the ESD charge is only the metallic object as in FIG. 8. In the case of a large inanimate intruder the ESD event is called a furniture ESD, and it originates from a specific conductive location on the intruder. Inanimate intruders include equipment carts without a human, as in FIG. 5, and with a human as in FIG. 6, and a human with a chair as in FIG. 7. The energy transferred from an intruder to a receptor during ESD depends on the impedance between them and on the energy dissipated in the arc. FIG. 9 shows an indirect ESD event. The equipment victim is irradiated by the fields, where the principal source is a result of the ESD (i.e., the ESD arc) and a function of the intruder mass and the receptor mass.

5. ESD WAVEFORMS

Human and furniture ESD current waveforms are described in [1] Knowledge of these waveforms is important for designing the waveform generators used for ESD testing of electric devices. We describe here a few typical waveforms given in [1]. Current waveforms due to ESD events generally fall into two categories: those with extremely steep initial slopes and those without extremely steep slopes.

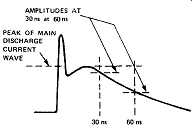

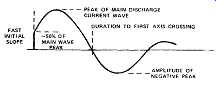

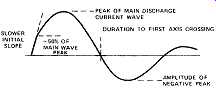

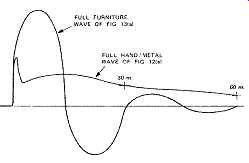

FIG. 10 shows a current waveform originating from a lower voltage (approximately 4 KV) human hand/metal ESD event having a steep initial slope (approximately 1 ns) and an initial spike. FIG. 11 shows a hand/ metal ESD current wave initiated from a higher voltage (or from a sharper point or slower approach). This wave displays a much slower initial slope and has no initial spike or pulse. Furniture ESD events produce current waves with steep initial slope, but they don’t always have an initial spike, which occurs less frequency with such events. The main discharge wave for furniture ESD is typically oscillatory, since the total impedance in the discharge circuit path is not much more than the resistance; in other words, there is minimal damping in the circuit. Two typical furniture current waves with fast and slow initial slopes are shown in FIGs. 12 and 13, respectively. For comparison FIG. 14 shows an overlay of waveforms in FIG. 10 and FIG. 12 for hand/metal ESD and furniture ESD, respectively. Observe that the initial slopes of the two are the same, and also note the oscillatory nature of the full waveform in the furniture case. The transient pulses due to ESD events can cause logic errors, process resets, and even physical damage to semiconductor devices. The fast rise time pulses due to ESD may interfere with clock transitions in digital circuits and thus can give rise to upset and malfunction [9].

FIG. 10 Full hand/metal wave.

FIG. 11 Hand/metal wave without initial spike.

FIG. 12 Full furniture wave (fast front).

FIG. 13 Furniture ESD current waves.

FIG. 14 Overlaid current waves from hand/metal and furniture ESD current

waves.

6. HUMAN BODY CIRCUIT MODEL

As mentioned earlier, humans are the most common source of ESD to cause undesirable interference to electronic systems in their vicinity. For analytical and/or estimation of interference effects thus produced, it’s convenient to use an RLC equivalent circuit to model the path of an ESD involving a human body with its arms and fingers and an object EUT (equipment under test) through which a discharge takes place. Such modeling is described in [1-5].

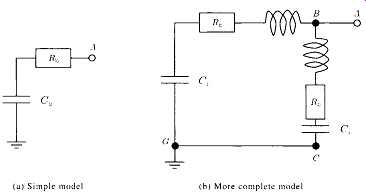

The three sources of ESD that are of greatest interest to a designer of electronic equipment, and that are therefore the most important to model, are (1) body/finger ESD (discharge from fingertip without an associated metal object; FIG. 2), (2) body/metal or hand/metal ESD (discharge from a metal object in contact with a hand; FIG. 3), and (3) furniture or inanimate object ESD (discharge from a cart, chair or other inanimate object with or without a human in conductive contact with the object; FIG. 8). Equivalent circuit models for the above are described in detail in [l] and also in [24,9]. Approximate equivalent circuit models to study ESD from human body are shown in FIG. 15, where in the simplified model C,, represents the body capacitance to ground (typically cb - 150 pF) and R,b represents the body resistance (typically - 1.5 K-Ohm). In the literature one typically finds cb - 60-300 pF and Rt, - 1.5-10 KR.

FIG. 15 Equivalent circuits: (a) simple model and (h) more complete model

for the human body. (a) Simple model (b) More complete model.

When terminal A is brought to contact with a grounded conducting body, the capacitor cb discharges, causing the flow of current that may result in conducted and radiated interference. FIG. 15b shows an improved model where a small inductance L is added and the branch B-C is a model of the human hand. In this model the discharge current has a fast rise-time component (less than 1 ns) due to branch B'C and a slower component (100 ns) due to branch BG. More elaborate models and their descriptions are given in [1] and in the other references cited.

7. ESD GENERATOR AND ESD TEST

From the discussions in Section 11.5 it can be seen that voltage/current pulses of desired shape and intensity are required to carry out meaningful ESD testing on equipment and its components. Such pulses can be obtained from an ESD generator. Its discharge electrode for contact discharge has a sharp pointed tip whereas the electrode has a round tip for air discharge tests. The test generator usually has provisions to deliver test voltage/current pulses at various intensity levels. Further details about the generators and their applications are described in [4]. For a given piece of equipment under test (EUT), its immunity to ESD is estimated by carrying out the following tests: (1) air discharge test where a charged electrode is brought close to the device under test so that electrostatic discharge takes place in the form of a spark between the charged electrode and the EUT, and (2) contact discharge test where the charged electrode is held in contact with the EUT and the discharge is initiated by means of a switch in the generator circuit. Further details for the tests are given in [4].

REFERENCES:

1. IEEE Guide on Electrostatic Discharge (ESD): Characterization of the ESD Environment, IEEE Std. c 62. 47-1992, IEEE Press, New York, 1993.

2. H. W. Ott, Noise Reduction Techniqz4e.y in Electronic Systems. 2nd ed., Wiley, New York, 1988.

3. C. R. Paul, Introduction to Electromagnetic Compatibility, Wiley, New York, 1992.

4. V. P. Kodali, Engineering Electromagnetic Compatibility & IEEE Press, New York, 1996.

5. N. Boxleitner, Electrostatic Discharge and Electronic Equipment: A Practical Guide for

6. M. I. Montrose, Printed Circuits Board Design Techniques for EMC Compliance, 2nd ed., I. Electromagnetic Compatibility for Industrial Process Measurement and Control Equipment, Part 2: Electrostatic Discharge Requirements, International Standard, IEC 80 1-2, International Technical Commission, Geneva, 1991

7. Designing to Prevent ESD Problems, IEEE Press, New York, 1989. IEEE Press, New York, 2000.

8. Guide to Electrostatic Discharge Test Methodologies and Criteria for Electronic Equipment, IEEE c 63. 16, Institute of Electrical and Electronics Engineers, New York, 1991. Press, Ann Arbor, 1995.

9. C. Christopoulos, Principles and Techniques of Electromagnetic Compatibility, CRC.

Prev. ------ Next