AMAZON multi-meters discounts AMAZON oscilloscope discounts

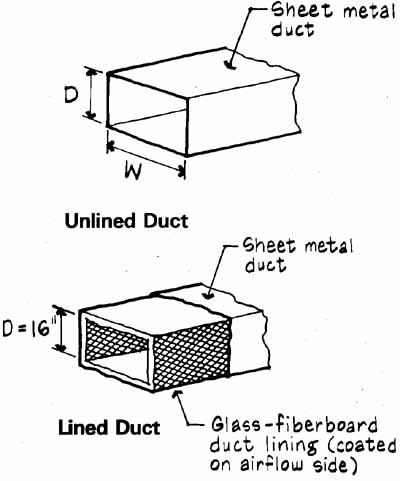

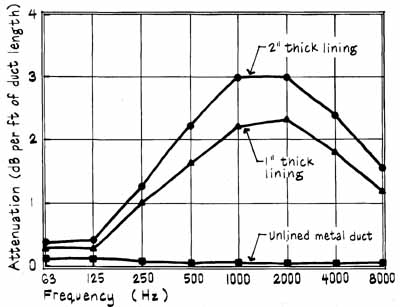

Glass-fiber linings are used in supply and return air ducts to prevent the propagation of noise inside the ducts and cross talk between rooms. The curves below show the sound attenuation in decibels per foot of duct length for internal glass-fiber linings (on all four sides of duct). The 1- and 2-in-thick lining data represent attenuation for a 16-in deep mechanical duct. Due to flanking along duct walls, maximum total attenuation (that is, dB/ft times ft of duct) is usually less than 40 dB. Actual data from independent testing laboratories should be used whenever it's available. The attenuation shown on the graph below would be less for larger ducts with linings of identical thickness.

The higher the ratio of lined-duct perimeter [ ( W + D)] to cross-sectional open area (W X D), the higher the attenuation of noise within the duct. Be careful because ducts with high attenuation for duct-borne noise propagation (e.g., foil-backed glass fiberboard) may provide little resistance to sound transmission through their walls. Fibrous duct linings should be coated with binders to hold surface fibers together.

As also shown on the graph, metal ducts without linings provide lithe attenuation with distance. However, glass-fiber wrappings used for thermal insulation can provide some damping of duct surface radiation, although attenuation with distance will still be far below that of internally lined ducts.

Next: Mufflers

Prev: Air Duct Layout Examples