AMAZON multi-meters discounts AMAZON oscilloscope discounts

Pipe Isolation

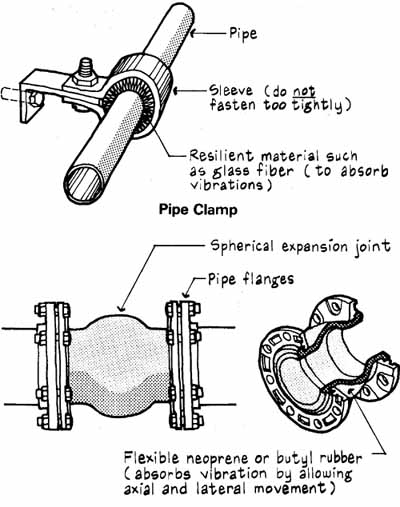

Water pipes should be located away from acoustically sensitive areas such as auditoriums, theaters, conference rooms, and private offices. When this is not possible, the least number of turns, valves, and fittings should be used because these components can create turbulence and noise. Piping runs should be resiliently isolated by ceiling hangers or floor-mounted supports (e.g., neoprene, steel springs, or glass-fiber or neoprene-lined metal clamps, as shown below) to prevent transmission of noise and vibration into the building structure.

For domestic water-piping systems, use neoprene gaskets or “hubless” pipe (straight ends) joined by neoprene sleeves. These resilient connections can prevent direct metal-to-metal contact between sections of pipe.

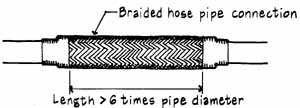

Butyl rubber expansion joints can be used to allow pipes to expand and contract and to reduce the noise and vibrations transmitted along the pipe walls. The preferred location for the flexible pipe connection is parallel to the axis of the equipment rotating shaft. For high-pressure or high-temperature applications, use stainless steel braided hoses although they are not as effective isolators as flexible neoprene connections.

Pipe Clamp; Pipe Expansion Joint

Flexible Metallic Pipe Connection

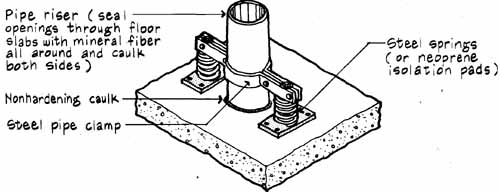

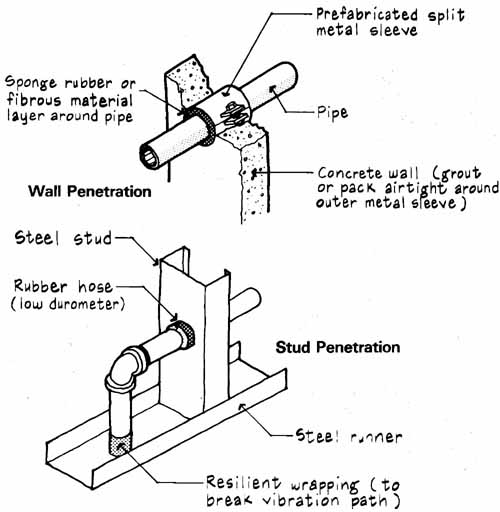

When piping systems penetrate the building structure, openings should be oversized for the full depth of the opening so that the pipe can be supported on both sides of the opening without contact. Pipe perimeter should be packed with fibrous materials and caulked airtight on both sides. At locations with especially large openings to be sealed, bags filled with mineral fiber can be used as packing. When commercially available pipe isolation sleeves are used in double-wall constructions, be sure each layer has an independent sleeve so that the two layers will not be tied together. Avoid solid anchorage of long vertical pipe risers to floor slabs. Use steel clamps that are in turn supported by neoprene pads or steel springs, as shown below. Noise from water flow can often be reduced by using pipes with thicker walls.

Stud Penetration: Sponge rubber or fibrous material

layer around pipe

Water Flow Velocities

To prevent water flow noise generated by turbulence, velocities should be controlled by using large pipe sizes and large radius elbows, or upstream pressure-reducing devices. The table in SUGGESTED WATER FLOW VELOCITIES: it gives the recommended maximum water flow velocities for domestic water systems.

Water Hammer

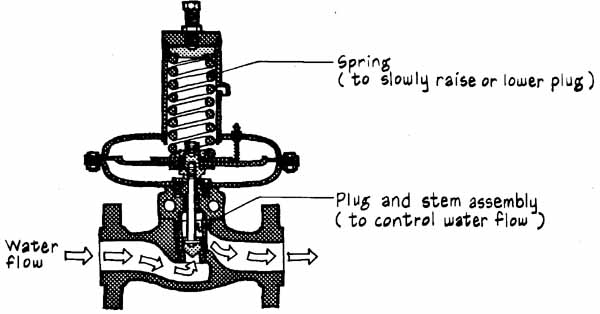

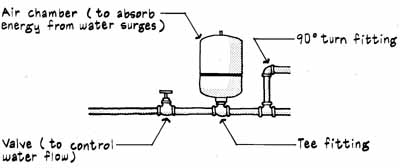

Noise in piping systems can occur when a rapidly closed valve abruptly stops a moving column of water (e.g., quickly closing a sink faucet). The resulting forward and backward water surge within the piping produces pounding noises called water hammer. Water hammer noise can be prevented by using spring-operated valves to slowly close valve stems. In addition, the installation of gas-filled stainless steel bellows units can effectively absorb the surge of water at abrupt pipe turns. Compressed air chambers or accumulators also mitigate the effects of water hammer in long pipe runs.

Note: In areas subject to earthquakes, piping for fire suppression systems should be protected by supports at pipe joints, approved flexible connections, sway bracing, and the like.

References

L. H. Bell, Fundamentals of Industrial Noise Control, Harmony Publications, Trumbull, Conn., 1973.

M. Rettinger, Acoustic Design and Noise Control, Chemical Publishing Co., New York, 1973, pp. 339-345.

Next: Suggested Water Flow Velocities