AMAZON multi-meters discounts AMAZON oscilloscope discounts

There are two force-measuring methods:

direct and indirect.

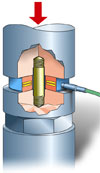

Direct Force-Measuring Method

Direct

force-measurement requiress splitting the component or member perpendicular

to the load path so that the engineer is able to mount the calibrated-force

sensor. As this substantially interferes with the existing structure,

the mounted force sensor must meet the component's strength and rigidity

requirements. The measuring range of the sensor must be wider than the

variation in the process force to be measured. Nevertheless, this method

of mounting has the major advantage that, irrespective of its point of

application, the force acting can always be measured accurately and with

good linearity.

Application: 1-component and multicomponent force measurement in the laboratory, measurement of small forces, wherever measurement of absolute force is required.

Best sensors for this application: Calibrated one-component and multi-component force sensors.

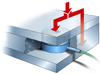

Indirect Force-Measuring Method

If

very large forces have to be measured or the component can't be split,

a force-shunt method of measurement should be used. The sensor is mounted

in a suitable position along the component's load path and firmly clamped

to the structure. It then measures only part of the process force to be

determined. This component is smaller or larger depending on the mounting

configuration. The advantage of this method of mounting is that it involves

relatively little interference with the existing structure. Only one sensor

with a smaller measuring range is still needed. Once the sensor has been

mounted, in-situ force calibration is required to determine the sensitivity

of the measurement setup.

Application: Should only be used for measurement of forces with fixed point of application. E.g. monitoring press processes.

Best sensors for this application: one-component force sensors and strain sensors.