AMAZON multi-meters discounts AMAZON oscilloscope discounts

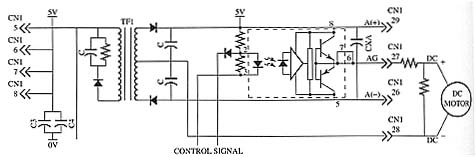

If the amplifier and motor operate as a proportional control, the motor will have an acceleration ramp and a deceleration ramp for each point the robot moves to. The proportional control uses both velocity sensors and positional sensors. ill. 1 shows an example of this type of DC amplifier and motor diagram. From this diagram notice that the amplifier for the DC motor is similar to push-pull amplifiers and DC servo amplifiers. From this diagram also note that the AC supply voltage for the amplifier circuit is provided by an individual transformer secondary winding. Each motor on the robot will have its own transformer to supply AC voltage. Note that the transformer is a center-tapped transformer so the AC voltage can be rectified to full-wave DC with only two diodes. The DC voltage is provided to the transistor section of the amplifier as a bus connection. The transistor section uses two transistors as a push-pull amplifier. The control signal for the transistors is optically isolated so the amplifier transistors don't feed back excessive voltages to the axis control module. The axis control module will control the bias on the base of each transistor to provide sufficient voltage and current to allow the DC motor to accelerate or decelerate smoothly under all load conditions.

Above: ill.1: Electrical diagram of a DC servo amplifier.

Notice that this type of push-pull amplifier uses a center-tap transformer

to eliminate an additional pair of diodes in the rectifier section and a pair of transistors in the amplifier section.

Note that the positive terminal of the DC motor is connected to the transistors in the amplifier, and the negative terminal is connected to the center tap of the transformer. This allows the voltage to the positive lead of the motor to receive positive voltage from the top transistor to rotate clockwise, or negative voltage from the bottom transistor to rotate counterclockwise. The center-tap transistor allows this type of DC amplifier to operate with two fewer diodes and two fewer transistors, which cuts down on the number of components that can become faulty.

| Top of Page | PREV: Amplifiers, Motors, and Feedback Sensors | NEXT: AC Amplifiers |