AMAZON multi-meters discounts AMAZON oscilloscope discounts

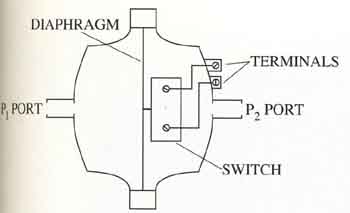

The diaphragm sensor can be modified to measure the amount of difference that exists between two sources of pressure. This type of sensor is called a differential pressure sensor and the chamber surrounding the diaphragm is designed so that pressure can be applied to both sides of the diaphragm. The side of the diaphragm that has the most pressure applied to it will cause the diaphragm to move toward the side that has less pressure. The movement of the diaphragm can be detected and converted to linear motion to activate a switch or be used to move the arm of a linear potentiometer. Springs can be added to one or both sides of the diaphragm to adjust the amount of differential pressure required to make the diaphragm move. The differential pressure sensor can be manufactured to respond to a very small amount of pressure difference. The figure below shows an example of a differential pressure sensor. The pressure ports for this type of switch are identified as P1 and P2.

above: Example of a differential pressure sensor.

Notice that this sensor uses the diaphragm to make two chambers. Pressure

is applied to each chamber and the amount of difference between the two

pressures can be sensed.

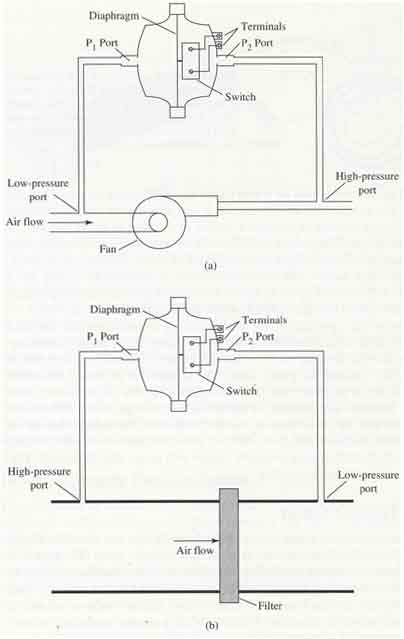

A typical industrial application for a differential pressure switch includes

testing the pressure difference across a fan or a water pump. If the pump

is running, a high-pressure area will develop in front of the pump (P1), and a low-pressure area (P2) will develop behind the pump inlet.

The amount of pressure difference will be called delta P (ΔP). (Note

that Δ is the symbol for the Greek letter delta and it's used to

indicate the amount of difference or change.) The differential pressure

sensor can also be used to measure the pressure difference across an air

filter. When the filter begins to become dirty, a pressure difference

will develop across the filter and the differential pressure sensor will

sense this difference. The figure below

shows diagrams of these examples.

above: (a) A differential

pressure sensor used to measure the pressure difference across a water

pump. If the pump is running, a high pressure will develop in front of

the pump and a lower pressure will develop behind the inlet of the pump.

(b) A differential pressure sensor is used to determine how dirty an air

filter is.

Prev. Page: Bourdon Tube Pressure Sensor | Next Page: Bellows Pressure Sensors

Related pages: Load Cells | Flow Meters