What is a soldering iron? To some people it is a bit of plastic with a hot thing on the end which is used to stick bits of metal together, and apart from that it is a complete mystery.

The numbers and types of soldering iron on the market today make choosing the correct iron very difficult. It is essential that the correct iron is used for each job, but at this stage it must be emphasized that there is no such thing as a general purpose iron that will do all soldering jobs.

We will therefore deal with what you will need to know about the soldering iron when making your first purchase.

One major warning before we proceed. A modern soldering iron is a precision instrument and several manufacturers now make their elements with ceramic insulation. The purpose of this is to make the iron most suitable for use with modern electronic components and it does of course mean that the iron must be treated very much more carefully than in the past. You must never knock the solder off the end of the bit, drop the iron, use it to force a part out of its connection or apply excess pressure to the handle when soldering.

All these actions will cause the ceramic insulation to break causing premature element failure. Please do not then blame the manufacturer as it is an operator fault not a manufacturing fault.

The factors you need to consider when selecting your soldering iron can be broken down as follows:

What type shall I choose?

If electrical, what voltage shall I choose?

What wattage do I need?

What size of iron do I need?

Let us deal with these in order.

Type

Portable Gas: This type of iron is becoming very popular because it is the first useful type of portable iron available.

Providing you have a canister of gas available to refill the iron then it will be able to be used over a long period. This type of iron tends to be available only in the range up to 50 watts for standard soldering and is therefore only useful for the smaller job. However, it comes very much into its own for field work where power is not available. The other main advantage is its lack of a cable. Some of the more expensive units do have a flame head available as an extra. This will of course enable you to solder much larger items where the flame is not a problem.

Rechargeable: This was the first type of portable iron introduced many years ago. The biggest disadvantage with this type is its limited usage per charge. Most irons of this type will, theoretically, give you up to 100 joints per charge, which in most cases is per 24 hours. However, my experience is that this translates in practice to only 4 minutes continuous use in the 24 hour period between charges. This can be extended by having the iron continually on charge when not in use.

Electrical: This will be the most popular type chosen but even here the choice will be wide. Electrical soldering irons have been around for years and are therefore the type most of us are used to. They range from cheap imported irons (suitable only for general purpose soldering around the house or car) to very expensive solder stations suitable only for industry.

So what factors need to be considered when purchasing or selecting the type of iron needed for your particular application?

Voltage

The voltage you choose will be dependent on where or how you intend to use the iron.

220-240 Volt: This will be the most popular choice and is therefore the most common voltage of soldering irons available in the United Kingdom and Europe.

100-120 Volt: This voltage is mainly used in the Far East or the United States and Canada. However, it is now commonly used on building sites and other primary installations in the building and construction trades. Unless you have this voltage available then 100-120 volts should be avoided and under no circumstances should the iron be plugged directly into a 240 -volt mains supply.

24 Volt: This is a specialist voltage and again unsuitable for domestic use. Some factories now work with 24 volts. On a other use tends to be for irons that are plugged into solder stations. These are only suitable for that use and for no other.

12 Volt: This is the other popular voltage and can be used wherever a suitable 12 -volt power supply is available. One word of warning though. Most people do not realize that when the voltage is decreased then the current INCREASES.

Therefore even small items at 12 volts will use large amounts of current (amps). A simple rule of thumb is that for every 25 watts of device you require 2 amps of power at 12 volt.

It will therefore be seen that a 1.5 amp model railway tram former is not suitable for a 25-watt soldering iron and will probably burn out in a very short time. It will also be seen that 12 volts is really impractical for soldering irons with a wattage greater than say 50 watts, due to the cost and size of the transformer system required as well as the cable size that would need to be fitted to prevent the cable catching fire.

What Wattage Do I Need?

If you have already been looking at soldering irons you have probably been baffled by all the different wattages that are on the market. You will probably have seen 12, 15, 18, 2C, 25, 30, 40, 50 watt ratings and many more, even though many of them look to be the same size physically.

These variations are explained by the different designs of soldering iron and their various efficiencies. The wattage tells you only how much electricity the product will use and not its heat related performance, which is determined by the amount of heat that the element can transfer to the soldering bit before the bit cools off.

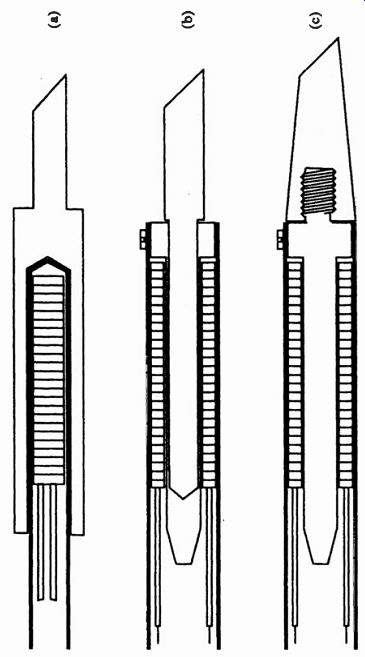

There are three main designs of iron currently available (see Figure 1.1).

(a) The Bit Sliding Over the Element: This type of iron is the most efficient, in that all the heat from the element must pass through the bit to get to the air. Therefore, with this type of construction a smaller wattage of iron can be used against the other two types.

(b) The Bit Sliding Inside the Element: This is the most inefficient construction, having a large surface area of the element exposed to the air as against the bit. This type of iron would only be about 40% as efficient as the type (a).

(c) The Bit Screwed Onto the Element Block: This style is more efficient than (b) but much less efficient than (a). Its biggest drawback is that if the bit seizes onto the element block then the element will either be seriously damaged or destroyed rendering the iron completely useless.

This therefore explains the various wattages on the market and in my experience a 25 -watt version of style (b) is equivalent to an 18-watt version of style (a) or a 22 -watt version of style (c).

What Size of Iron Do I Need?

As mentioned at the beginning of the guide there is no such thing as a general purpose soldering iron. Most irons are available with interchangeable bits to give them a wider sphere of use but even here the applications would be limited within the range of the iron. For example, an 18-watt iron should be available with bit sizes from 1.5mm to 6mm, the 1.5mm size being suitable for micro electronic circuits and the 6mm for slightly thicker wires.

Fig. 1.1 Soldering iron element and bit designs

Throughout the guide I will try to recommend the type and size of iron as well as solder types and voltages that I would recommend for a particular application.

One final point when buying a soldering iron is that you must decide whether it is going to be used regularly or only occasionally. This will determine the type of iron you will buy. Make sure that spares, especially bits, are easily available and that there is a simple guarantee. If you are not sure as to the availability of spares then you should consider purchasing them at the same time as you buy the original soldering iron.