There are many accessories available all of which are useful for particular applications. This Section deals with the most popular ones that you may wish to purchase when you buy your soldering iron.

Stand

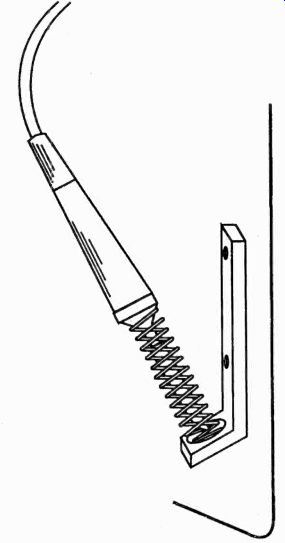

Fig. 2.1

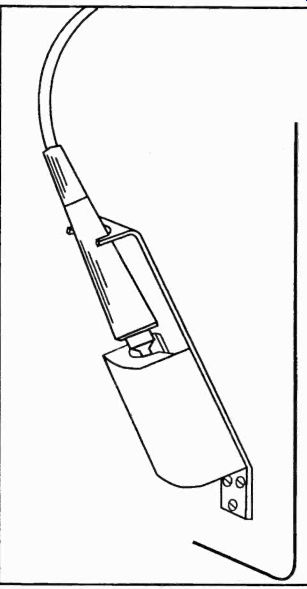

Fig. 2.2 Metal fully enclosed type stand

The soldering iron stand is one of the more important accessories available and is especially necessary for electrical soldering irons. It must be remembered that the soldering iron bit is probably at a temperature in excess of 400°C when at rest and apart from the obvious electrical problems of pulling the plug out when tripping over the lead or of melting through the cable, there is also the problem of ruining clothing or tattooing your body! Many a hobbyist has a burn mark on their stomach where they have accidentally leaned over the bench where the soldering iron has been hooked onto a nail at the edge of the bench It is very easy to do and very painful.

There are two basic types of stand available on the market at present, the spring type and the metal fully enclosed type.

The spring type (Figure 2.1) is the most common but must be treated more carefully. In the cheaper versions it is possible for the weight of the soldering iron to bend the spring sufficiently to allow the soldering iron bit to touch the spring, so that the spring eventually becomes very hot and again can cause serious burns when touched. Make sure when buying that the spring stand is strong enough for the iron you have and that the bit cannot touch the spring. Make sure also that the stand has a very heavy base otherwise the whole lot could be as dangerous as the use without the stand. It is my experience that most spring stands would need to be screwed down to be fully safe but I am sure that this would not go down very well at home if you should screw it to the front room table! The metal fully enclosed stand (Figure 2.2) is the better type. Not only does it tend to allow the bit to be fully enclosed and away from any metalwork, but because of its construction it tends to have a very low centre of gravity and is therefore more difficult to knock or pull over. Most of this type tend to hold the iron more securely.

One word of warning when using any type of stand with a soldering iron with a temperature control facility which registers the temperature of the soldering iron rather than just adjusts the temperature. As the electronics detect the temperature at the bit it is essential that the bit is always in open air and not touching the stand or any other surface. If it does then a false message is sent back to the control electronics which has the effect of allowing the element of the iron to get hotter and hotter to overcome the load. This will seriously reduce element life as well as prematurely burning out the bit.

Solder Sucker

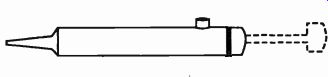

This is sometimes called a "vacuum pump", and is a very useful tool for repairs or when correcting mistakes (Figure 2.3).

Fig. 2-3 Solder Sucker

It works in conjunction with your soldering iron and, as its name implies, sucks the solder from the joint. The principle of the solder sucker is that it is primed and held in one hand while the soldering iron is held in the other. When the iron has melted the solder then the button on the solder sucker is pressed and the solder will be sucked up into the barrel of the solder sucker. If done properly, this will leave the area around the repair free of most solder. In the case of a larger area it may be necessary to repeat the process several times.

If used carefully then it is possible to remove solder from all the pins of an integrated circuit (chip) to enable it to be removed without damaging the circuit board. This will be dealt with further in later Sections.

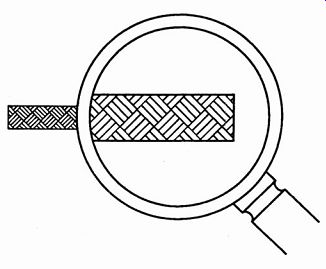

De-solder Braid

This is another repair product and is actually copper brad (Figure 2.4) which is laid on the area where solder needs to be removed. The main problems with this product are, firstly that you will need a large soldering iron bit to heat it up, and secondly if the solder is allowed to cool before the braid is removed then there is a serious danger of the printed circuit track being lifted from the board thus destroying the circuit 'board. Having said that, the de-solder braid is a very useful item for removing larger amounts of soldering providing the dangers outlined above are overcome.

Fig. 2-4 Cu de-solder brad.