By ALFRED ZUCKERMAN /Vice President, Engineering

Benjamin Electronic Sound Corp.

Description of Staar mechanism, which permits slot loading and automatic changing of cassettes. System has been licensed to 25 manufacturers throughout the world.

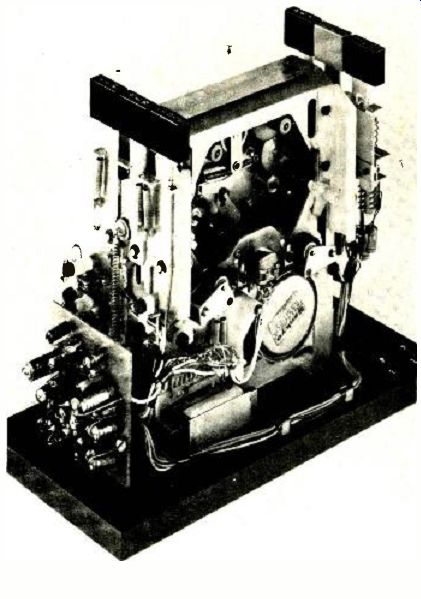

---- Basic slot-loading Staar transport mechanism for cassettes.

THE Staar System is a slot-loading transport mechanism for cassettes. It permits cassettes to be simply pushed into a slot in the transport much like the endless-loop cartridges are inserted into their players. The mechanism was developed by Staar S.A., a Belgium-based company specializing in equipment for the audio field. The firm has pioneered in record changer, tape-transport, and dictating-machine design for over 30 years, and holds many basic patents in these areas.

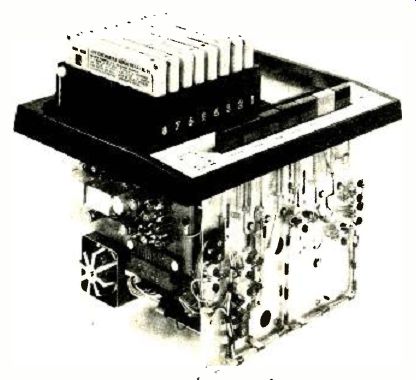

--- An 8-cassette automatic changer mechanism using same system.

The basic Philips compact cassette configuration, a refinement of the RCA Victor 1959 twin-hub cartridge, was introduced to the U.S. market by Norelco in 1965. This system required insertion of the cassette along the axes of the reel hubs and capstan. This was accomplished by broadside-loading, which was acceptable for home and portable use but was unsuited for auto use where the space requirements and distraction were considered excessive.

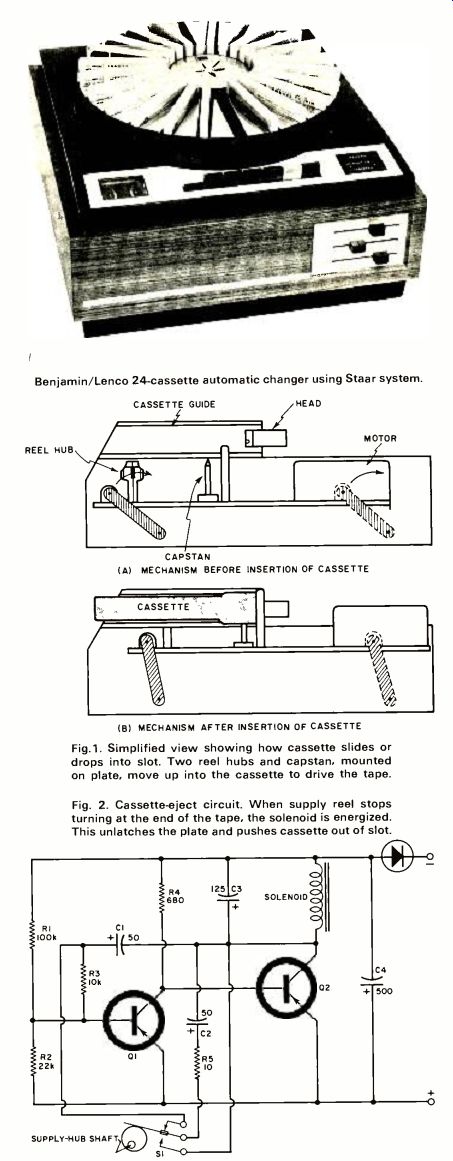

Theo Staar, President of Staar S.A., recognized this problem initially and in 1965 he filed a patent application which covered a mechanism that permitted slot-loading. As the cassette is pushed into the slot, it bears against pins attached to a plate on which is mounted the motor-flywheel-capstan system and the two hubs (Fig.1). The plate is hinged at four points by parallel-action linkages attached to the main chassis. As the cassette is inserted the hubs and the capstan swing up into the appropriate openings, engaging the reels fully and pinching the tape between the capstan and pinch roller in the final position when contact is made between the tape and the head.

When the hinged plate is fully engaged, it is latched into position. Release of the plate and ejection of the cassette can be effected by several means:

1. A simple eject button which mechanically unlatches the plate.

2. A solenoid which duplicates the action of the eject button. This solenoid is connected to a sensing circuit which automatically ejects the cassette at the end of the tape.

3. This solenoid and sensing circuit provide a means of automatically ejecting the cartridge in the event the power is turned off while the cassette is engaged. This protects the capstan follower and tape.

Many systems have been devised to sense the end-of-tape condition. Those which sense program material are subject to unwanted false triggering by a long silence on the tape.

Those which sense a conductive tab on the face of the tape are limited only to those cassettes that are so equipped.

Space limitations preclude the insertion of tension-sensing switches in the cassette.

Staar devised an ingenious system based on the motion of the supply reel which avoided all of the limitations just outlined. By coupling a s.p.d.t. switch (S 1) to a cam on the supply hub, shaft information is fed into the eject-solenoid circuit (Fig. 2). The circuit consists of two direct-coupled transistors driving a solenoid. Ordinarily R1 and R 2 bias Q 1 to a cut-off condition which results in Q2 operating in saturation and activating the solenoid. When power is applied, however, the charging current of C1 drives Q 1 to saturation for the brief period before the motor comes up to speed and the tape starts moving. When this occurs, the contacts of S 1 alternately short C2 (through low-value resistor R 5) and connect it across C1. The average recharging current of C2 is sufficient to bias Q 1 to saturation, cutting off Q 2 and keeping the solenoid un-activated. When the tape motion stops, C2 is either shorted out of the circuit or charged up fully. Soon Q1 is no longer forward-biased; it stops conducting and Q 2 is driven to saturation, energizing the solenoid.

Time constants are such that after 1.5 s. the solenoid is activated, cassette is ejected, and system is turned off.

Another interesting feature covered by Staar patents is the "Sensitune" device. In the basic unit, Fast-Forward and Rewind functions are initiated by the lateral motion of the Eject lever which is spring-loaded and returns to the normal play mode when released. In the Sensitune model, this lever locks into either fast mode. An auxiliary tape head senses the program material on the tape and, in conjunction with associated circuitry, automatically senses the (minimum) 4 seconds of silence between selections. The circuit then automatically actuates a solenoid which unlocks the fast-mode lever, returning to the playback mode. This permits the user to skip a tune or replay a tune by simply activating the fast-mode lever in the desired direction.

A more recent development is a transport mechanism which automatically senses the end of the tape on the cassette and reverses tape direction to play the other tracks.

The Fast-Forward and Rewind push-buttons automatically reverse function when the tape reverses so that the Fast-Forward button functions as Fast-Forward irrespective of the direction of tape motion.

A further development for home entertainment use is a cassette changer which incorporates the control features of the bidirectional unit just described. In this unit, a small tray which accepts up to eight cassettes is loaded onto the top of the machine. The first cassette drops into a slot, plays, reverses, plays the return tracks, and then rises to the tray. The tray advances to permit the next cassette to play.

This process continues until the last cassette is played at which time the cassette returns to the tray and the mechanism shuts itself off. There is also a 24-cassette version of the changer which uses a rotating tray.

Licenses for the slot-loading cassette mechanism, primarily for use in automobiles, have been issued to 25 manufacturers throughout the world. Licenses to manufacture the changers, however, have been issued to only four manufacturers. These are Ampex in the U.S., Plessey in England, Matsushita in Japan, and Lenco-Italiana in Italy (distributed in U.S. by Benjamin Electronic Sound Corp). Benjamin /Lenco 24-cassette automatic changer using Staar system.

REEL HUB CASSETTE GUIDE MOTOR CAPSTAN (A) MECHANISM BEFORE INSERTION OF CASSETTE (B) MECHANISM AFTER INSERTION OF CASSETTE

Fig.1. Simplified view showing how cassette slides or drops into slot.

Two reel hubs and capstan, mounted on plate, move up into the cassette

to drive the tape. Fig. 2. Cassette-eject circuit. When supply reel

stops turning at the end of the tape, the solenoid is energized. This

unlatches the plate and pushes cassette out of slot.

Also see: Nomogram Aids Voltage-Drop Calculations