| PREV: | NEXT: |

Relay logic has been the main type of industrial control for electric circuits ever since the relay was first designed. The relay is versatile since it can have more than one set of contacts, which can be any combination of normally open or normally closed contacts.

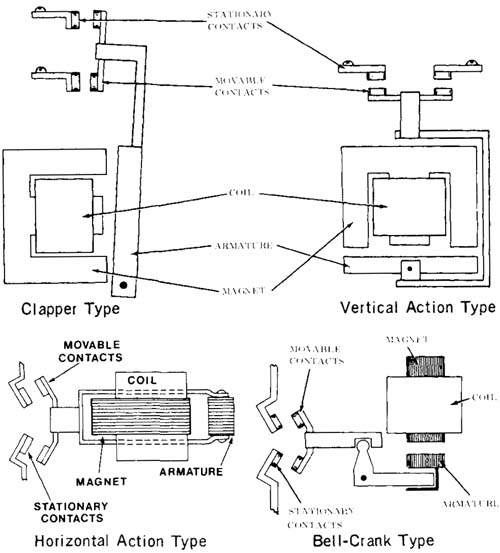

AMAZON multi-meters discounts AMAZON oscilloscope discountsThe relay is an electromagnetic device that has a coil made of wire. The wire is normally coated (laminated) with plastic or a similar substance to insulate the coil wires from each other and other parts of the relay so they don’t create an electrical short circuit. When current is passed through the coil, it becomes a strong magnet. Mounted on a plastic carrier, the contacts of the relay are electrically isolated from each other. The plastic carrier is connected to a piece of metal called an armature, which is drawn into the coil’s center where it becomes an electromagnet. The movement of the armature causes a normally open set of contacts to move to the closed position, or a set of normally closed contacts to move to the open position. ill. 1 shows examples of four types of armature assemblies found in different types of relays.

Above: ill. 1: Types of armature assemblies found on various types of relays. MOVABLE CONTACTS, MAGNET, STATIONARY CONTACTS, Horizontal Action Type Bell-Crank Type, Clapper Type, Vertical Action Type.

The horizontal-action-type armature has a set of stationary contacts shown on the far left, and a movable aramature. The armature in this device moves to the left when the coil is energized, which causes the contacts to close. When the current is turned off and the coil is no longer magnetized, a spring will move the armature to the right.

The bell-crank-type armature has an L-shaped arm connected to a pivot point. The armature in this type of relay pulls one end of the arm up when the coil is energized, which shifts the movable contacts to the left so that they press against the stationary contacts. When current is turned off to the coil, the weight of the armature will cause the end of the arm to drop, which will pull the movable contacts back to the right.

The clapper-type armature has a long arm connected at one end to a pivot point. When the coil is magnetized, the middle of the arm is pulled to the coil, which will cause the movable contacts to move to the left until they touch the stationary contacts. When power is removed from the coil, a spring will pull the contacts back to their open position.

The vertical-action-type armature is shaped like a backward letter C. The contacts are connected to the top part of the armature, and the bottom part is pulled to the coil when it becomes magnetized. When the armature is pulled up, the movable contacts will touch the stationary contacts. When power is turned off to the coil, the weight of the armature will cause it to move down to its original position where the contacts are open.

| Top of Page | PREV: | NEXT: |