AMAZON multi-meters discounts AMAZON oscilloscope discounts

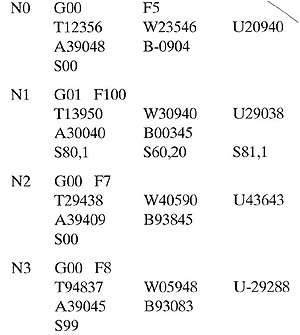

Typical point-to-point programs will contain a step number, positional data, operational codes, and a feed rate (speed) for each step. The positional data will list the number of pulses on the encoder that each motor (each axis) will display when the robot reaches the position. The pulses are considered raw positional data since they don't relate to a specific point. The robot controller records the pulse data from the encoders when the robot is programmed and it simply moves the robot motors until the encoders match for that position.

The XYZ program is similar to the point-to-point program except the positional data are listed as XYZ positions rather than the number of pulses each motor or axis will move. It's important to remember that the XYZ position is the place in the work envelope where the end of the robot wrist will be for that position. The important point to remember about an XYZ program is that one could measure the cell to determine the coordinates of any other points and enter them in the program and the robot would move to those points. This makes the XYZ program useful in programs that are developed from CAD drawings (CAD/CAM) or by off-line simulation software. CAD/CAM is computer-aided drafting (design) and computer-aided manufacturing.

The continuous-path program samples the position of the robot continually as it's moved through its path and records these data points in memory. The velocity of each motor is also recorded for each point that's recorded. When the robot is in the run mode, it repeats these points and motor velocities so that the robot repeats the program exactly the way that it was recorded. Anytime an input or output signal is received or sent during the time the robot is moving, it's recorded so that the robot will repeat this action when it's in the run mode. For instance, the robot will remember where it's supposed to turn on a spray nozzle if it's spray painting, and repeat it at exactly the same point in the program each time the program is replayed.

The fixed-stop robot will generally use a program that allows one to

put the axis moves in the sequence they are executed. Sometimes this type

of program is actually a PLC program, or a sequencer of, some type.

Above: ill.1 Example of a point-to-point program.

One may begin to recognize the type of path control the robot is using and the type of program one would expect to see in the robot.

| Top of Page | PREV: | NEXT: |