AMAZON multi-meters discounts AMAZON oscilloscope discounts

Positive-stop control is used in many robots that utilize pneumatic cylinders. This type of control energizes a solenoid valve to extend or retract the cylinder at the appropriate time. When the extend solenoid valve is energized, air is let into the pneumatic cylinder and the shaft inside the cylinder begins to extend and it moves until it hits a stop at the end of its travel. When the solenoid for retraction is energized, air is let into the other side of the pneumatic cylinder and the shaft will begin to retract until it hits the stop at the end of its travel. In some cases the stroke of the cylinder is short, and in other cases the stroke of the cylinder is long. When a short-stroke cylinder is used, the robot makes noises each time the cylinder hits a positive stop. This noise is referred to as a bang and this type of robot is sometimes called a bang-bang robot.

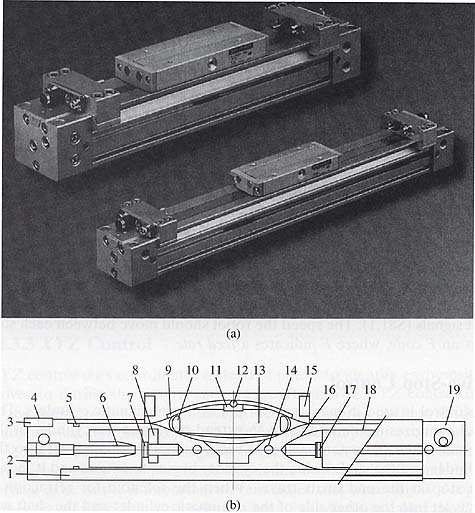

In some positive-stop robots, more than one stop can be used by placing the stops outside the robot. In these applications a rodless cylinder is used (see ill. 1). The rodless cylinder does not have a rod that must extend from the cylinder.

Above: ill.1 (a) Examples of rod-less type pneumatic

cylinders. (b) A cut-away diagram of a rodless cylinder. 1. Cylinder tube,

2. Head cover left, 3. Belt clamp, 4. Head cover WR, 5. Tube gasket, 6.

Cushion ring, 7. Cushion seal, 8. Piston packing, 9. Scraper, 10. Belt

separator, 11. Coupler, 12. Slide table, 13. Piston yoke, 14. Spring pin,

15. End cover, 16. Wear ring, 17. Piston, 18. Dust seal band, 19. Head

cover right.

Instead it has a piston inside the cylinder tube that moves from end to end when air is used to move it. The rodless cylinder also has a coupler that's mounted on a rail on the outside of the rod. The coupler has a strong magnet that's attracted to the piston inside the cylinder. When the piston on the inside of the cylinder moves, the strong magnetic field also moves the coupler on the outside of the cylinder.

A rod-type pneumatic cylinder that's 8 ft long must have 16 ft of space to move in since the 8 ft rod must be able to be retracted into the cylinder and extended 8 ft out of the cylinder. The main advantage of the rodless cylinder is that the same 8 ft cylinder only needs 8 ft to operate in, since there is no rod to extend out of the cylinder. When the rod-type cylinder is fully extended, it may tend to droop because it's not supported. The coupler in the rodless cylinder is supported at all points along its travel. The programmable logic controller (PLC) is useful for this type of control. It can energize and de-energize the solenoids that route air to the correct part of the pneumatic cylinder in the exact order of sequence that's needed to move the robot into position.

| Top of Page | PREV: | NEXT: |