AMAZON multi-meters discounts AMAZON oscilloscope discounts

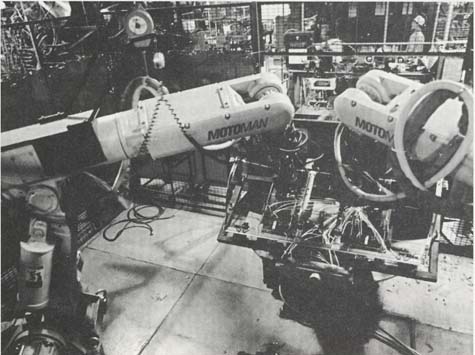

Robots have been used in spot-welding applications for many years. The major advantage of using the robot in this type of application is that the robot can move the 150 lb. spot-welders with relative case. This job is very strenuous for humans and the fumes from the welding are a problem. ill. 1 shows a typical spot-welding cell where eight robots are used to spot-weld automotive bodies as they pass by the robots on a continuous production line.

Above: ill. 1: Application of a spot-welding work

cell.

The robots in this work cell have extended reach so that they can reach both inside and outside the body to make the welds. Since the automotive bodies are on a continuous production line that does not slow or stop while the robots are welding, the robots must have software that helps them track the body as it passes through the work cell.

When the automotive bodies enter the work cell, the first robot on the left side and the first robot on the right side begin to track the frame and body and locate their first welds. Since the robot begins to track the frame and body as they move along, the robot will keep pace with the body and continue to apply welds to the exact location. When the bodv has moved far enough into the work cell, the second robot on the left side and the second robot on the right side begin to track the body and finish making welds. After the body has traveled passed the first two sets of robots, the remainder of the robots continue to make welds until all of the welds have been made. The robot program has been timed so that it can easily complete all of its welds while a robot is in reach of the body.

In some welding cells each robot is programmed to make all of the welds for the robot on either side of it. This is necessary in the event that one of the robots has a failure. The line can be slowed down slightly while one robot completes welds for the robot that's next to it on that side. Most robots of this type have sufficient memory to store several different programs including programs for different types of body shapes. This allows the robot to use sensors to identify which body is arriving at the work cell and change to the program that matches the body. This function permits the factory to make more than one type of body style without major problems during the changeover.

| Top of Page | PREV: Industrial Robots Used In Typical Work Cells And Manufacturing Cells | NEXT: Loading and Unloading Bonding Machines |