AMAZON multi-meters discounts AMAZON oscilloscope discounts

Before we begin the explanation of adding reset control to gain control, we present an example of this type of control. The image below is of a plastic injection-molding machine, also called a plastic molding press. The temperature at the barrel of the press must be controlled within +/- 5°F at setpoints from 300°F to 600°F. The reset control helps the temperature controller hold the temperature to within +/- 5°F.

Adding Integral (Reset) to the Formula to Change Bias Automatically

When the integral is added to the original formula, the type of control is called PI (proportional and integral) control. Integral is a mathematical term that's used in controllers to determine the amount of error remaining anytime the PV does not equal the SP. In mathematics, you may have completed calculations using integration to determine the amount o f error under the curve. The controller uses the integral in a similar manner. To be precise, the integral term is added to the original algorithm with the Kc X E term and its job is to automatically change the bias (offset) at a time period specified by the integral time. The formula for a proportional and integral (PI) controller can be slightly different from controller to controller. It's also important to understand that a formula for positioning systems (like a system that controls a valve positioner) would be different from a formula for motion systems (like the velocity controller for a robot drive). The formula for the valve positioning controller would allow the output to remain at any value between 0-100% when the SP is reached, while the motion controller system for the robot drive would set the output to 0 when the robot reached its final position (SP).

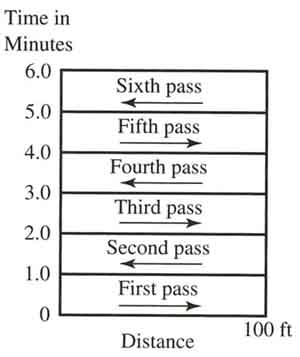

A simple way to understand the function of integral is to think about the way you mow the lawn. ill. 1 shows a diagram of the way you'd mow your lawn. Notice that you'd mow from left to right on the first pass, and then turn around and repeat the next pass from right to left. One would continue walking back and forth across your lawn until all of the grass was cut. In this example we will only look at the first two passes. Let's say that it took 1 minute to make the first pass. If you change the time it takes to make the second pass, the speed that you must walk must also change. E.g., if you mow the second pass in 30 seconds (0.5 minute) you'd need to walk twice as fast, and if you took 120 seconds (2 minutes) to mow the second pass you'd need to walk half as fast.

Above: ill. 1: Example of mowing a yard to show the function of integral

action in a controller.

For this example we will equate the time it takes to mow the first pass to the response the controller gets from gain-only control. This means the gain action causes the first amount of change. The integral action then simply repeats the amount of change (mowing the second pass) in some given amount of time. The integral action continually adjusts (repeats) the output signal by the same amount of the original change caused by gain until the PV equals the SP. You'll notice that if the integral time is decreased, the repeat (second pass) must occur more quickly. This means the output signal would have to be increased to ensure that the process could move fast enough. If the integral time is increased, the time it takes to repeat the first pass would be slowed down. From this example one can now see that the integral part of the formula will continually adjust the output signal after gain causes the first amount of change in the system after the SP is changed. If the integral value in the controller is small, the amount of change caused by the action of gain will be repeated more rapidly and the controller will respond more rapidly.

If the integral value in the controller is made larger, the amount of change caused by gain will be repeated more slowly.

One should notice that at this time we have not actually given any values to integral, rather we have used the terms larger and smaller. This refers to the fact that some value for integral is already placed in the controller, and this amount is either decreased to make the controller response faster or it's increased to make the response slower.

PREV: Problems

with Adding Bias Manually

NEXT: Using Values for Integral Action