AMAZON multi-meters discounts AMAZON oscilloscope discounts

Now that we know the action that the integral causes we can apply units to the values that represent it. Since integral action is the time it takes to repeat the action that was first caused by gain, we can describe an integral as the number of minutes per repeat. This can be shortened to minutes/repeat. In some controllers the time may be calculated in seconds rather than minutes. Since the time in these units refers to real time, it will be possible to use a strip chart recorder to graph the changes in the response for the system and determine the amount of change for the integral value.

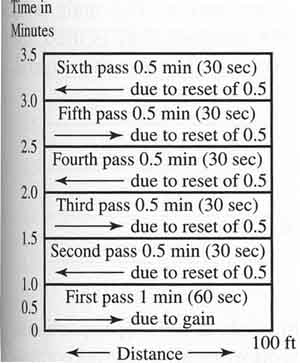

In the lawn-mowing example, the first pass was completed in 1 minute. If the integral action completed the second pass in 1 minute, the response would be exactly the same as the first pass. If the second pass was completed in 2 minutes, the response would show that the speed on the second pass would be slower and it took twice as long to repeat the action. ill. 1 shows a graphic representation of what would happen if the second pass took 30 seconds. From this graph notice that the speed would be increased so that it would take half as long to repeat the original action. From this example, notice that by specifying the amount of time to repeat the original action caused by gain, you can modify the total system response.

Above: FIG. 1 Graph of changes caused by lowering the time for

the second pass to 30 seconds.

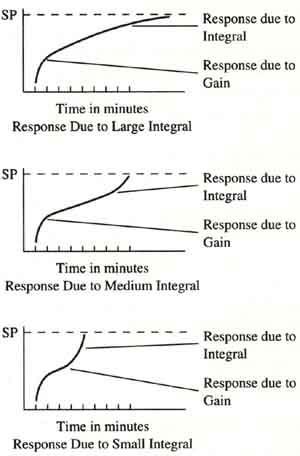

The effects of a large, medium, and small integral time can be shown in graph form. ill. 2 shows examples of these three types of response. Again it should be noted that the relative terms of small, medium, and large are used so that notice what will happen to the system if the integral is increased or decreased. In the graph at the top of the figure, notice that since the integral time is larger, it will take longer for the system PV to reach SP. In the middle graph, the integral time has been reduced, and the system responds more quickly so it can reach SP more quickly. The graph at the bottom of the figure shows the response for the smallest integral, and notice that the PV gets to SP very quickly.

Above: FIG. 2 Three graphs showing the effects of large, medium, and small integrals.

By specifying the integral time, you can make the controller change the output more rapidly or more slowly to meet any conditions that the system requires. E.g., if you were heating a furnace or the barrel of a plastic injection molding machine, you may be concerned that the temperature does not rise too quickly. One could specify a rather large integral time such as 2 minutes, and the amount of original change caused by the gain action could be added to the bias every 2 minutes. This is why the units for integral action are referred to as repeats per minute. This means that when you place a value in the controller for integral action you must remember you are specifying the amount of time in minutes that you want the controller to repeat the original action caused by the gain calculation. (Please note that some controllers use seconds instead of minutes where faster response times are required.)

PREV: Industrial System that uses Gain and Reset

NEXT: Reset Action