AMAZON multi-meters discounts AMAZON oscilloscope discounts

ON-THE-JOB TRAINING

The major difference between 25 years of experience and 1 year of experience repeated 25 times is OJT. Good, well-planned, on-purpose OJT is the heart and soul of an adult learning program. Adults must learn by doing, and the workplace is the best laboratory. The three major segments of OJT include setup, implementation, and evaluation. A well-defined lesson plan is as important with OJT as it is for classroom instruction.

You must involve the employees in the development of this program. Their input and feedback will be critical every step of the way. The employee safety committee can also be used as a training committee and should oversee every aspect of the training program development and presentation.

Note that safety topics are especially suitable for presentation in an OJT format. The best way to memorize critical safety procedures is while actually performing them under field conditions. Note also, however, that special supervision is required when personnel are learning safety procedures with energized equipment.

Setup

As noted previously, all training must be properly planned. Good training implies that it is being done on purpose. The setup portion is the most critical step of all and must be properly executed because it serves as the foundation.

Step 1. Define the employees' job functions. This step, often called a job analysis, is critical to all training but especially to OJT. Since OJT takes place while actually on the job, you must know what your employees do before you can train them. This is a simple concept, but it is surprising how many organizations miss this step. The performance of the job analysis can be as simple as asking your employees to make a list of what they do. The analysis of time sheets is another good approach. A final source of information is to ask your supervisors to list job functions for employees.

Notice that interviewing supervisors is the last of the three approaches. Unfortunately, company management and supervision are not always as closely in tune with day-to-day employee activities as they should be. This is not always true, but too often it is.

At the conclusion of this step, you should have a complete listing of the major jobs performed by your employees; for example, one major job is to remove motor starters from motor control centers with energized buses.

To simplify this step, concentrate on major job functions. Detail can be added as the OJT program develops over the years.

Step 2. Isolate the job functions that are practical and measurable. For example, you may have one task such as troubleshooting the south plant UPS system. While troubleshooting is a trainable skill, it is very difficult to measure troubleshooting ability in an OJT environment. On the other hand removal of starters from motor control centers is measurable and practical. Initially, only the practical and measurable skills should be included in the OJT program. As your program's sophistication increases, you may wish to add more cognitive skills.

As each job function is determined, it should be identified with a simple numbering system. For example, the starter removal might be job function number 1; cable testing, job function number 2; and so on. This makes it possible to keep records for which job functions employees have received training.

Step 3. Break each job function into tasks, subtasks, and detailed procedures. Continuing with the starter removal as an example, we might develop several tasks including the de-energizing of the cubicle, proper use of safety equipment, mechanically removing the starter, and so on. The safety subtasks would include, but not necessarily be limited to, determining the proper personal protective equipment required to perform the job, the inspection of rubber insulating gloves and leather protectors, inspecting and testing the proper voltage-measurement device, performing proper voltage measurements, application of proper lockout-tagout procedures, proper technique for removal of the starter, proper inspection and application of safety grounds, and so on. The detailed procedures can be developed either in-house or from manufacturers' literature.

Step 4. Develop training objectives for the tasks and subtasks. The objectives should have the measurement criteria contained within them. The following examples use the motor starter removal as their subject.

Task

1. The employee shall independently remove a low-voltage motor starter from its cubicle. The job shall be performed using all applicable company safety standards.

Subtasks

(a) The employee shall perform a safety inspection of a pair of class 00 low-voltage rubber insulating gloves and the leather protectors.

(b) The employee shall wear a flash suit, previously inspected rubber insulating gloves, hard hat, and face shield.

(c) The employee shall stop the motor and de-energize the starter module. He or she shall demonstrate proper procedure and stand in a safe work location while per forming these steps.

Here we have shown only one of the objectives; there would be several more, one for each safety task and one for the mechanical procedures.

Step 5. Develop the written materials necessary to support the program. The following should be developed as a minimum:

1. Complete set of written objectives.

2. Written, detailed description of each task. To accomplish this portion, manufacturers' literature may augment materials developed in-house.

3. Diagrams, illustrations, or examples.

4. Employee record cards. The cards should have space for the employee's name, classification, and other demographic data. The majority of the card should contain space for completed job functions (by identification code), time of completion, and instructor's initials indicating successful completion.

Implementation

The implementation phase of an OJT program should be a simple extension of the setup phase.

Step 1. Select several of the job functions to be used as trial runs of the OJT program. At the same time, select an experienced group of employees to receive the initial training.

Develop the record cards for each employee.

Step 2. Thoroughly indoctrinate each of the test employees in the program and give them advance knowledge of what is expected. Of course, if you have been properly including the employees in the development phase, this step will not be necessary.

Step 3. Introduce the training, one job function at a time. Scheduling should be made by working the program into the normal work schedule. That is, when plant scheduling requires relay testing, use the opportunity to provide the OJT.

Step 4. Have the employee's supervisor go over the task with the employee and make certain the employee thoroughly understands what is required of him or her. Remember, this is training and the supervisor may be the instructor. The employee should perform the work, with the instructor giving guidance. The instructor should watch the employee per form each task and make certain all tasks are performed within measurement criteria.

Step 5. After each training session is completed, thoroughly evaluate the results. See the next section for a more detailed description of evaluation.

Step 6. Gradually involve each existing and new employee in the OJT program. Any time an employee is called upon to perform a new job function or task, the OJT program should be implemented and the employee's record card should be updated accordingly.

Evaluation

Step 1. The results each employee obtains should be measured against the criteria established during the setup phase. Do not make any assumptions based on just one or two employees. Poor performance by several employees could mean the program is bad, or it could mean that more classroom training is required.

Step 2. Interview the employees in a confidential manner. Give them a chance to critique the entire training program. All aspects-materials, implementation, and objectives- should be reviewed.

Step 3. Interview the instructor to get his or her feedback.

Step 4. Based on the first three steps, modify the program as required.

Step 5. Every two years, review the program from top to bottom.

Conclusion

One major misstep taken by many organizations when they enter the world of OJT is to forget the key word-training. On-the-job training is not an on-the-job test. Rather it is on-the-job training. Do not forget to provide the necessary field instruction as the program progresses.

In general, OJT will not stand alone. It must be accompanied by good classroom instruction and/or self-training properly implemented and monitored. As stated in the previous section, OJT can be the most cost-effective of all the parts of a training program.

TRAINING CONSULTANTS AND VENDORS

Only very large companies can justify having their own, completely self-supporting, in-house training organizations. Even when in-house organizations exist, they frequently use outside vendors for support and special programs. In other words, you should use training consultants and vendors for the same reasons you use any consultant or vendor-when time, personnel, expertise, or economics makes it impossible to perform the task yourself.

Training consultants fall roughly into three categories-those who provide canned pro grams, those who develop and present tailored programs, and those who provide training analysis. Of course, some companies fit into more than one category.

Canned Programs and Materials

Programs. Companies that provide the short one-week, manufacturer's type of seminars have proliferated since the early 1960s. Training programs are available in electrical safety, circuit breaker maintenance, relay testing, substation maintenance, transformer testing, uninterruptible power supplies, programmable logic controllers, and a host of other such topics. Usually these courses are from three days to two weeks in duration. They are normally presented either in a training center or at a hotel with adequate meeting facilities.

Some of them are equipment-specific, while others are generic in nature. Several of these programs consist of classroom as well as hands-on training, which provides a more thorough training program, essentially consisting of classroom instruction and OJT in one package. Pricing varies, but these seminars generally offer a very economical approach when you have only one or two employees to train.

Learning-by-mail programs, called correspondence schools, also fall into this general category. Some companies have been providing programmed mail-order instruction for decades. The correspondence schools are especially useful for vocational-type training at a more generic level.

The vocational technical schools (votechs), both private and public, fill yet another need in this arena. Many companies are requiring two-year associate degrees or the equivalent for employment in certain technical areas. The votech schools provide such programs. Most of the votechs have evening courses, allowing students to attend in their free time.

Each of these three types of programs has its own advantages. The one-week seminar is very intensive and provides training in very specialized areas in a hurry. The correspondence schools are very effective for students who have schedules that make attending classes difficult. The votech types of programs are excellent for those students who wish to start at the beginning and learn the entire discipline.

Materials. Some organizations sell training materials such as programmed courses, videos, interactive video, and/or computer- or Web-based programs. The principal difference between these materials and the correspondence school is that the materials may be used to present training to many people in one organization. These packages may also cover very specific equipment maintenance, safety, and/or operations.

Tailored Programs

When a company is truly committed to highly cost-effective training, it should opt for the tailored program. Often surprisingly affordable, tailoring may be as simple as taking a canned one-week course and teaching only about the equipment that is in use at the particular plant or company. Most of the large vendors are glad to do this sort of tailoring.

Other vendors will develop entire tailored presentations to a client's specification.

This type of service is most useful when your organization has a large number of people to train in a given area or areas. For example, immediately prior to a major maintenance shut down, you may wish to have five or 10 of your maintenance personnel trained in cable testing and maintenance at your own facility. Such training is usually much more affordable than sending individual employees to single presentations.

Some training consultants will develop completely tailored programs based on existing industry standard texts, for example, safety programs based on NFPA 70E or substation maintenance based on an electric equipment text. Such programs are extremely effective and are generally no more costly than those described previously.

Training analysis

Sometimes, a company may have no idea what its training needs are. This is less common than in years past, but it does still happen. Training consultants can be retained to provide an entire training systems analysis. The major areas in such a development include needs analysis, job and task analysis, and curriculum development.

Needs Analysis. Also called a front-end analysis, the needs analysis is the starting point for any training program. The overall method is covered in many industry standards such as those by ASTD. The general principle is quite simple. Desired performance is compared to actual performance for the workers under consideration. If the desired performance is below nominal, training is indicated.

Job and Task Analysis. This portion is usually a part of the needs or front-end analysis.

The procedure involves defining each employee's job functions in measurable, objective terms; breaking each job function into tasks and subtasks; and finally writing these job functions, tasks, and subtasks as measurable learning objectives. These learning objectives are then used as the basis for the training programs.

Curriculum Development. The actual curriculum is written and/or selected to fulfill the learning objectives developed during the job and task analysis. However, how this is accomplished may be quite flexible. For example, if a given group of employees has the responsibility to perform routine maintenance on the uninterruptible power supply, the learning objectives may be met by sending the group to one of the canned courses previously discussed.

Evaluating t raining Vendors and Consultants

Evaluation of any training must be based on the learning objectives. To know how well you are doing, you must know what we intended to do. Training must be objective-based and done on purpose. Proper evaluation demands that such an approach be used. With this in mind, vendor training can be evaluated using four simple criteria.

Does the Vendor Provide Properly Documented, Objective-Based Training? If the answer is no, do not use that vendor. Of course, this does not apply directly to some of the situations described in this guide. However, even training analysis consultants can be checked for competency in and knowledge of objective-based learning.

Does the Vendor Listen Closely to Your Desires and Counsel You If He or She Believes That You Are Wrong? One of the most difficult things for any consultant to do is to argue with his or her client. Remember, the client pays the bills. Therefore, if your consultant listens, and then counsels (or argues) with you when he or she believes you are wrong, that consultant has your best interests at heart.

Does the Vendor Provide Only Qualified and Competent Personnel? Consultants are only as good as the people they employ. Take the time to quiz the individuals that your consultant provides. Ask for resumes, and, where applicable, interview the individuals. Even qualified people will not be effective if they have a personality conflict with you.

Did the Program Meet the Objectives That Were Set Out at the Beginning? Do not depend on course critiques and/or personal evaluations of attendees. Give quizzes where applicable.

Sit down with employees and have them review the material they learned. Develop your own short quiz based on the course materials, and administer it to your employees. The quiz can be administered orally, in written form, or as a field-type performance quiz. (For example, one task might be to "test this relay like they taught you at school.") As a corollary to this last question, always insist that a vendor administer performance quizzes as part of a training program. Quizzes accomplish three objectives:

1. They measure the student's performance.

2. They measure the trainer's performance.

3. They measure the course's success.

In some cases, union contracts may make quizzing difficult or impossible; however, since the quizzes also measure the quality of the training that occurs, many unions are eager for their members to be tested. In this way, they know their members are receiving proper and adequate training.

Conclusion

The use of training consultants is really no different in concept than the use of any other consultant or contractor. You should first determine what you need, monitor what you are getting, and, finally, evaluate what you got.

TRAINING PROGRAM SETUP-A STEP-BY-STEP METHOD

Introduction

Among the many difficulties faced by employers wishing to establish a viable electrical safety program is the need to validate that workers have the proper background, skills, and training as required by OSHA and NFPA 70E. Unfortunately, the existing standards do not address detailed methods that allow employers to validate that an employee has truly "received training in and has demonstrated skills and knowledge in the construction and operation of electric equipment and installations and the hazards involved." The program described in this section uses long-recognized industrial education procedures such as job and task analysis, skills assessment, and training needs analysis to develop and validate a program that will provide the highest level of compliance with existing regulatory and consensus standards.

Background

All of the modern regulatory and consensus standards allow only "qualified persons" to perform work that requires approaching energized conductors and circuit parts. OSHA defines a qualified person as one who has received training in and has demonstrated skills and knowledge in the construction and operation of electric equipment and installations and the hazards involved. (29CFR1910.399)

===========

Table 1 Explanatory Notes for the Definition of a Qualified person (From 29CFR 1910.331, .332, and .339)

[ Location in 29CFR:

1910.331

1910.332(b)(3)

1910.399

]

[

Text The provisions of 1910.331 through 1910.335 cover electrical safety work practices for both qualified persons (those who have training in avoiding the electrical hazards of working on or near exposed energized parts) . . .

Additional requirements for qualified persons. Qualified persons

(i.e., those permitted to work on or near exposed energized parts) shall, at a minimum, be trained in and familiar with the following:

• The skills and techniques necessary to distinguish exposed live parts from other parts of electric equipment.

• The skills and techniques necessary to determine the nominal voltage of exposed live parts, and

• The clearance distances specified in 1910.333(c) and the corresponding voltages to which the qualified person will be exposed.

Note 1: For the purposes of 1910.331 through 1910.335, a person must have the training required by paragraph (b)(3) of this section in order to be considered a qualified person.

Note 2: Qualified persons whose work on energized equipment involves either direct contact or contact by means of tools or materials must also have the training needed to meet 1910.333(C)(2).

Note 1: Whether an employee is considered to be a "qualified person" will depend upon various circumstances in the workplace. It is possible and, in fact, likely for an individual to be considered qualified" with regard to certain equipment in the workplace, but "unqualified" as to other equipment. (See 1910.332(b)(3) for training requirements that specifically apply to qualified persons.)

]

===========

OSHA also offers some additional clarification in several locations as shown in Table 1.

Unfortunately, none of the regulations give clear methods for certifying that personnel are truly qualified in the OSHA sense. This can lead to situations in which the employer and employee are caught in a "no-win" scenario.

For example, several years ago a worker was injured in an arc-flash incident. This individual was a journeyman electrician with almost 25 years of direct, hands-on experience and training. He was working in an electrical switch that was identical to hundreds of others he had serviced over the years. The arc occurred when the worker allowed a grounded lead to contact exposed, energized conductors. These conductors were exposed via mounting hardware that was in a very difficult-to-reach location in the equipment.

Through subsequent investigation, it was determined that the worker did not know that the mounting hardware was directly connected to the energized bus through a plastic mounting piece. The design of the equipment predated the dead-front requirement of modern equipment. The injured worker had never realized that the exposed hardware was energized even when the switch was turned off.

The experience and the training history of the worker did not sway the OSHA investigator, who correctly determined that the worker was, in fact, unqualified. He had not recognized and had not avoided the hazard.

This puts employers in the difficult position of declaring that their employees are qualified for certain work, only to find out later that, in fact, OSHA disagrees. Short of OSHA certifying employees (a highly unlikely scenario), there seems to be no way to validate that employees are qualified.

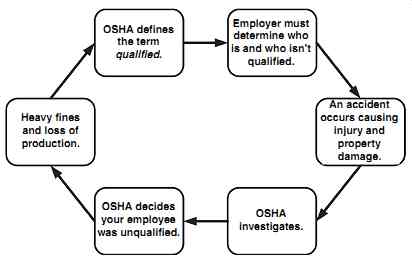

FIG. 2 illustrates the problem.

=======

FIG. 2 The regulatory training problem.

OSHA defines the term qualified.

Employer must determine who is and who isn't qualified.

An accident occurs causing injury and property damage.

OSHA investigates.

OSHA decides your employee was unqualified.

Heavy fines and loss of production.

========

The regulatory standards define the term qualified and give definitions and explanations as to what the term means. The standards also task the employer with the responsibility of determining who is and who is not qualified.

An accident involving a "qualified" employee occurs, which OSHA investigates. As a part of the evaluation, the OSHA investigator determines that one or more of the employees involved in the accident were not qualified. OSHA then issues fines and requires that the employer modify procedures and training.

At this point, the cycle starts again. The employer must again use the OSHA definitions to determine who is and who is not qualified, and so on.

In addition to the OSHA definition of a qualified person noted previously, OSHA pro vides some clarifying notes to this definition as follows:

Note 1 to the definition of ''qualified person:'' Whether an employee is considered to be a ''qualified person'' will depend on various circumstances in the workplace. For example, it is possible and, in fact, likely for an individual to be considered ''qualified'' with regard to certain equipment in the workplace, but ''unqualified'' as to other equipment. (See 1910.332(b)(3) for training requirements that specifically apply to qualified persons.)

Note 2 to the definition of ''qualified person:'' An employee who is undergoing on-the job training and who, in the course of such training, has demonstrated an ability to per form duties safely at his or her level of training and who is under the direct supervision of a qualified person is considered to be a qualified person for the performance of those duties.

A Plan

The following paragraphs present a program that can be used to validate the training of electrical workers as well as organize the overall electrical safety program. This program has been successfully deployed in many locations throughout the united States and continues to be introduced in a number of other plants.

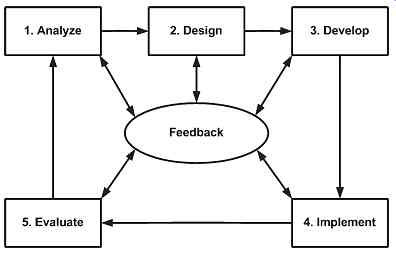

This validation program uses a holistic approach by integrating well-established engineering, technical, and educational methods. At its core, the overall strategy is based on the Instructional Systems Design (ISD) model, which is shown in FIG. 3.

FIG. 3 The instruction systems design (ISD) model.

Note that this model uses a "scientific" format that should be familiar to those in the engineering and technical disciplines. Note also that sufficient time and effort must be made in each stage to ensure that subsequent steps will be completed effectively. For example, shortening the analysis stage will create a disproportional increase in the time required for the design and development stages.

While the overall approach is designed to be a comprehensive methodology, it is flexible enough to be adjusted to fit the specific needs and situations found in a variety of different industrial, commercial, and utility cultures. The six major sections of the program are described in the following paragraphs.

Analyze

Needs Analysis. Not all organizations are in need of a comprehensive training effort.

Some, for example, may need only special skills training in a few isolated areas. A needs analysis is performed to determine what, if any, training is needed in the organization.

You should consult three sources to assess your needs-employees, supervisors and managers, and company performance.

1. Employees. Formally poll your employees for training requirements. Usually they know their shortcomings better than anyone. The poll should be concise and sincere.

Be prepared for a revelation because experience has shown that, more often than not, employers and employees have very different views about the state of their training.

2. Supervisors and managers. Extend the training poll to your management and supervision. Give them a chance to tell you where training deficiencies are causing problems.

Their input should be solicited for their employees' and their own training needs. Do not forget to include yourself in this analysis. Employees at all levels may need training.

3. Company performance. An honest evaluation of company performance can be one of the best sources of training needs assessment. The most obvious example of this element is in the area of safety. Do some departments have a consistent record of safety problems? Such a department is an obvious target for safety training. Remember to involve your employees and supervisors in the review and analysis of the material. The people who are going to receive the training should be involved at all stages. An electrical safety audit, as described in Section 13, can be used to satisfy all the requirements of the needs analysis. This comprehensive audit requires a minimum of two days for a small facility and a maximum of several days for a large facility. A combination of interviews, questionnaires, and site inspections creates a thorough assessment of the existing conditions. An exit presentation is held with key plant personnel to review critical findings. In most cases, severe hazards are discovered during the audit that can be corrected on the spot. A comprehensive report follows the audit within two weeks.

This report details the findings and recommendations of the audit and is the first concrete step in the process.

Job and Task Analysis. After the needs analysis is complete, you should have a well defined set of training needs. The next step is the performance of a job and task analysis (JTA) for each of the areas that requires training. This critical step defines the actual com position of a given job. The JTA involves the following three steps:

1. Employee interviews. Each employee is interviewed, and a listing is made of the jobs and tasks that he or she performs. The listing should be very detailed to allow for the development of performance objectives.

2. Supervisor and manager interviews. The department supervisors are interviewed to obtain their input regarding the jobs and tasks performed by their employees. This listing is compared to the one developed by the employee interviews, and modifications are made as required. Many training problems disappear when this step is performed since supervisors and employees develop a common understanding of the task at hand.

3. Job performance observation. Employees are observed in the performance of their jobs.

The job and task listings developed during the interviews are reviewed and refined to be consistent with actual performance. Remember that the actual performance of the given job is under question, so do not modify a JTA based on performance observation unless you are certain that the job is being performed correctly.

Arc-Energy Analysis. An arc-energy analysis that includes a short-circuit study, coordination study, and flash-hazard analysis is a critical part of the analysis stage and should be performed if it is not already available. Some companies may prefer to perform a "mini study" before any of the other steps to determine the severity of the flash hazard at their location. The results of this study will determine the minimum PPE requirements for workers, provide the required flash-hazard warning labels for each location, and introduce over all electrical safety requirements to plant personnel.

Because of the perceived cost of such a study, many companies opt for the use of the so-called simplified method as described in NFPA 70E and discussed in Section 3. The authors of this guide discourage this practice for several reasons, including the following:

1. The simplified method requires knowledge of much of the same baseline data including short-circuit duties and clearing times.

2. The simplified method frequently results in an overdressed workforce. In fact, if done conservatively, it should.

3. We have documented situations in which the simplified method actually results in underdressed personnel. That is, even when correctly applied, the simplified method may give results that will not provide adequate protection. While this occurrence is rare, even one time could result in severe injuries or death.

4. While most will agree that the current arc-energy calculation methods are a work in progress, they still provide the best available information of the degree of exposure. We owe our workers our best possible effort in determining the risk and attendant protection methods.

Design

Performance Objective Design. Based on the results of the JTA, a set of measurable performance objectives is developed. You may wish to develop training objectives in two tiers- terminal objectives and enabling objectives. Terminal objectives are broad-based objectives that represent the actual required behavior. Enabling objectives are "subobjectives" that define skills required to meet a given terminal objective. The following give examples.

• Terminal objectives. The employee will be able to test a Westinghouse induction disk overcurrent relay. The tests will be performed using the manufacturer's instruction leaflet, a transformer-loaded overcurrent relay test set and associated instructions, and the company-supplied test sheet. Test results shall be as defined in the relay instruction leaflet.

• Enabling objectives

1. The employee will be able to describe the purpose and use of each of the controls on the transformer-loaded test set.

2. The employee will be able to describe the pickup and timing adjustments on the Westinghouse induction disk overcurrent relay. (Add other objectives as defined from the JTA.) Note the specificity of the objectives. The regulations and standards are very clear in the requirement that employees must be trained on the equipment with which they work.

Structure Design. The information generated during the needs analysis, JTA, and performance objectives development is reviewed, and an overall structure for the training effort is defined. Of course, not all companies are going to need a large, expensive training center with a staff of trainers.

• In-house training. If you define an extensive training need with many ongoing course requirements, you may need to consider the development and use of an in-house training system. The materials for such training can include both specifically developed and/or vendor-supplied materials. On-the-job training is usually a very important part of in-house training.

• Vendor-supplied training. Specific skills such as cable testing, relay testing, breaker testing, and instrument repair may best be supplied by training companies that specialize in these areas. In fact, in some cases an entire program may be implemented through commercially purchased training.

• Self-study. Many skills can be learned effectively through one of the many self-study programs that are commercially available. Even if a program of this type is not purchased, employees should be encouraged (monetarily if necessary) to put in some study time on their own.

Infrastructure Design

1. Training department organization (a) the training department should report to the executive level of management. This is especially important for technical training departments.

(b) Training department supervisors should be technically qualified personnel. Furthermore, training supervisors should maintain a teaching schedule.

(c) Salaries for training department personnel should be equal to or exceed the salaries of equivalent level personnel in other departments.

2. Training facilities. The selection of a training facility will depend on the quantity and nature of the training that you wish to conduct. If you plan to use a lot of outside vendors, you may be able to use their facilities. Conference rooms, local meeting centers, and hotel facilities may also be viable alternatives. Specialized laboratory needs may require the construction of facilities. As an alternative to this, you may consider using your company work areas for laboratories; however, this is not recommended as a general practice.

Develop

Overall Training Structure. In some cases, the required training will be minimal and perhaps limited only to the specific qualification exercises necessary to ensure that all workers have the requisite technical and safety skills to perform their work safely. However, it should always be recalled that OSHA requires skilled personnel to be familiar with the hazards as well as the operation of the equipment, meaning that every worker must have a solid grounding in the hazards of electricity along with the various specific job requirements. The final training program will be a mix of several different training scenarios, including the following:

1. Prerequisite skills training from apprenticeship programs, public education, and/or validated on-the-job programs. The proof of such training may be a prerequisite for obtaining a job.

2. Formal classroom training to be attended by all personnel as they progress through their job structure. Such training may comprise one or a combination of the following:

(a) Internally developed and presented classes (b) external training from vendors, vocational schools, or community colleges.

(c) Formal on-the-job training requiring demonstration of skills in the presence of a supervisor with an appropriate qualification form.

Whatever the mix of training, there is only one way to ensure that workers are truly qualified. They must demonstrate their competence in a controlled environment, under supervision. To be fully qualified, workers must be trained on a switch of the exact type that they will encounter in the field. Trainees must demonstrate to a supervisor where all of the hazardous locations are and what steps/precautions should be taken to prevent an accident. FIG. 1 is a section of an employee on-the-job training qualification form for technical skills. Such forms should be used along with examinations and field demonstrations to ensure that workers are capable of performing all of the tasks to which they may be assigned.

Course Development. Courses must be developed or purchased to fulfill the objectives defined during the setup step.

1. Purchased materials. Both self-study and classroom materials are available for purchase from a variety of training vendors. Make certain that the purchased materials meet the objectives defined during the setup step.

2. Developed materials. Although somewhat more expensive, developing company-specific course materials has some distinct advantages. In the first place, your employees will tend to identify with materials that are obviously site-specific; moreover, presentation time is optimized since all material is company-specific. Note that these materials may be developed by either in-house personnel or consultants.

Implementation

The format of training implementation depends to a large extent on the structure of the facility and the training needs of the workers as determined in previous sections. However, the correct implementation is absolutely essential in the validation process. At each step, the workers must demonstrate their knowledge of the operation and the hazards of the equipment that they work on; moreover, they must demonstrate their ability to plan ahead and avoid those hazards by using appropriate safe work practices, PPE, and other precautions as required.

Of course, examinations and hands-on exercises will be developed based on the job and task analysis and other assessments discussed previously. Any missed questions should be reviewed with students until they understand why they missed them and have demonstrated their ability to answer similar questions correctly. In other words, where safety is at risk, 70 percent is not a passing grade. In fact, anything less than 100 percent success is insufficient when safety is involved.

The actual presentation of the training program will depend upon the extent and type of training being implemented. Some courses may be presented on an ongoing basis. For example, skills updates such as cable testing, motor and generator maintenance, and the like may be repeated immediately before maintenance intervals that will require those skills. Safety training should be repeated frequently, especially in areas such as lifesaving and CPR.

Training in areas such as basic electricity, mathematics, and other such topics is usually performed only once per employee. Large companies may need to schedule such training on a regular basis to allow for turnover. Smaller companies, however, may opt to use self training or correspondence courses for such topics.

Evaluation

Although evaluation is identified as a separate step, it should be an ongoing effort employed at every level of the training program. Five basic elements of the training program may be used to analyze its effectiveness-test review, course critiques, employee interviews, course content, and needs analysis.

Test Review. Examinations evaluate the student, the instructor, and the course. They should be administered for every training course. Tests should be reviewed for a variety of problems such as the following:

• Commonly missed questions. If one question or group of questions is consistently missed by all students, you have a problem with the instructor and/or the course.

• Consistently high or low grades. If the average grades on a test are consistently high or low, the course is probably too easy or difficult, respectively. Another possible cause of such a problem is that the course material does not fulfill the course objectives.

Course Critiques. Carefully review the course critiques for trouble spots. Consistently high or low evaluations may be an indication of a problem. Take the occasional "sour grapes" critique with a grain of salt.

Employee Interviews. Periodically interview employees to keep your finger on their pulse. Make certain that the employees are learning and that the training program is accomplishing what you intended.

Course Content. Electrical technology is changing rapidly. Although basic electrical principles remain the same, testing technology changes rapidly. Periodically you must have your course materials reviewed for technical accuracy and relevance. Nothing frustrates students more than learning yesterday's technology.

Needs Analysis. Periodically update the performance of the needs analysis. Make certain that the desired behavioral objectives are being met. Ask the following questions:

Has company performance improved as desired? Is employee and supervisor morale at the levels you wished to achieve? Is your company safety record acceptable? Tracking the Training Program. Keeping track of the feedback received during the various portions of the program is a monumental task, especially for very large companies. A system for tracking the training program should be implemented to document and verify all of the various training steps.

For example, during training implementation, records are stored in an electronic data base. Forms, queries, and reports are structured to allow the user to search for information relating to employees, hazards, or departments. Individual status reports are quickly and easily accessible and show each hazard for which the individual has completed training.

Such record keeping is critical to optimize safety and to serve as proof of training if an OSHA investigation occurs.

Whatever criteria were used to establish the original need for the training program must be evaluated. If the desired changes have occurred, then the program is meeting its goals.

Modification

Update and modify your training program based on your evaluation. Although this may seem obvious, a surprising number of companies evaluate their programs and then make no changes. An evaluation is useless if no changes are implemented.

| Top of Page | PREV. | Index |