AMAZON multi-meters discounts AMAZON oscilloscope discounts

Vibration sensors are sensors for measuring, displaying and analyzing:

- Acceleration

- Displacement

- Linear velocity

- Proximity

Above: A typical vibration sensor. This one is thread-mountable and made of stainless steel.

Vibration sensors may be used on a stand-alone basis, or as a component in a data-acquisition system.

Vibration sensors are available and sold in several forms, including:

- Packaged transducers

- Raw sensing elements

- As a sensor system or instrument which incorporates useful features such as totalizing, local or remote display and data recording

Above: An indicating model vibration transmitter.

This one comes in handy if you need to observe vibration (and take written

notes) at the equipment or machine being monitored.

Vibration sensors may have from one to three axes of measurement; the multiple axes normally being orthogonal to each other.

Vibration sensors operate on myriad physical principles. The most common are:

- piezoelectric

- capacitance

- null-balance

- strain gage

- resonance beam

- piezo-resistive

- magnetic induction

- newer MEMS technology allows for the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through micro-fabrication technology

Vibration sensor selection criteria:

- Accuracy (% of allowable error over the full measurement range of the device)

- Environmental conditions (in which sensor(s) are to be used in. Example: humidity, temperature, maximum shock and vibration the vibration sensors will be able to handle. I.e., amount of abuse the device can tolerate before it stops performing -- which is different from how much vibration or acceleration vibration sensors can measure.)

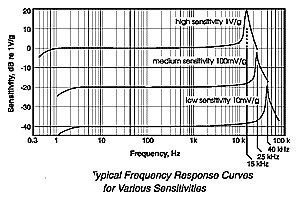

- Frequency range, in Hz (see figure below of frequency vs. sensitivity)

- Measuring range (in G’s for acceleration, inches/second for linear velocity (or other distance over time), and inches or other distance for displacement and proximity))

- Transverse sensitivity (this is the effect a force orthogonal to one being measured can have on the reading; given as % of full-scale of allowable interference). See figure below of frequency vs. sensitivity

- Other selection criteria include electrical output options (depends on the system being used with the vibration sensors). Typical analog options are: voltage, current or frequency. Digital output choices are: standard parallel and serial signals. Another option is to use vibration sensors with an output of a change in state of switches or alarms. Also, these sensors can have acceleration, velocity, or displacement as output by either integrating or differentiating their primary output.

|

|

Criteria for mounting vibration sensors:

- Stud mounting (most secure)

- Threaded on to machine, equipment or device being monitored (see thread-mount sensor below)

- Other methods include:

- Adhesive

- Magnets

- Wax

- Electrical and /or ground isolation may be required in certain cases (see sensor power schematic below)

- Triaxial mounting cubes (see figure beelow) may also be used to mount three vibration sensors together in an orthogonal configuration (this allows one mounting surface on the monitored device has to be used for all three)

- Your ultimate choice must be weighed based on your specific application and ability

|

Above: thread-mount sensor |

Above: Sensor power schematic |