AMAZON multi-meters discounts AMAZON oscilloscope discounts

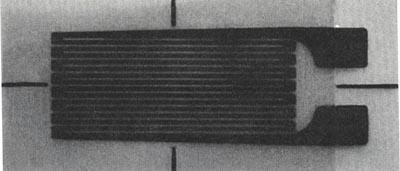

A strain gauge consists of a grid of very fine wire that is bonded to a surface. When the surface moves due to changes in pressure, the resistance of the wire changes. The strain gauge must be connected in a circuit such as a Wheatstone bridge so that the change in resistance can be converted to a change in voltage. The image below shows an example of a typical strain gauge. In this figure you should notice that the strain gauge looks like a long piece of wire neatly laid out on a flat surface in multiple rows. The strain gauge has two terminals that are the ends of the long piece of wire. The material that the strain gauge is mounted to is called the backing or carrier matrix. This material is flexible like a thin piece of plastic tape but durable so that it can hold the strain gauge wire in its proper position. The backing also is the material that the adhesive is applied to so that the strain gauge can be glued into place. The overall size of the strain gauge will range from less than 1 in. long for the smaller sizes and up to 10 in. long for larger ones. When you purchase a strain gauge, it will come mounted on its backing ready to be glued to the surface of the material that will move or flex when pressure is applied to it. e.g., a strain gauge could be glued to the end of the Bourdon tube or the bellows of the pressure gauges that were previously discussed. As pressure is applied to the Bourdon tube and bellows, they will deform or change and the strain gauge will monitor this change by changing its resistance. If the strain gauge is connected to a Wheatstone bridge, the amount of change in resistance can be converted to a change of voltage.

above: A typical bonded

resistance strain gauge.

On the left, a modern strain sensor from SMD.

Applications: Indirect force measurement on mechanical presses,

machine tools, high-speed production machinery, assembly units. Characteristics:

Very high sensitivity, extremely low acceleration sensitivity, also

suitable for measurements on moving parts, overload protected, ground-isolated

(optional).

On the left, a modern strain sensor from SMD.

Applications: Indirect force measurement on mechanical presses,

machine tools, high-speed production machinery, assembly units. Characteristics:

Very high sensitivity, extremely low acceleration sensitivity, also

suitable for measurements on moving parts, overload protected, ground-isolated

(optional).

Prev. Page: Bellows Pressure Sensor | Next Page: Types of Strain Gauges

Related pages: Load Cells | Flow Meters