AMAZON multi-meters discounts AMAZON oscilloscope discounts

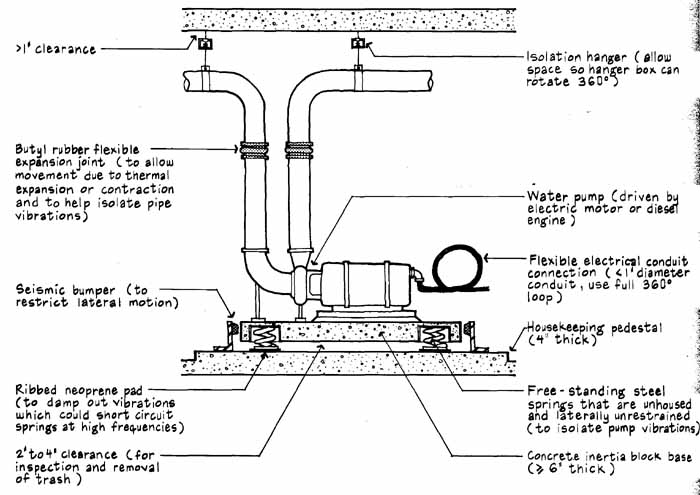

An example vibration-isolated water pump is shown below. The pump motor assembly ( > 5 hp) is supported by a concrete inertia block sized to support more than 2 times the fluid-filled pump weight plus all filled piping to the first isolation hanger. The length and width of the inertia block should be 30 percent greater than the length and width of the supported equipment.

Isolation hangers should be used to resiliently support piping for a distance of at least 150 times the pipe diameter (or preferably the complete length of the pipeline). Butyl rubber or nylon-reinforced neoprene expansion joints can reduce noise and vibration transmission along pipe walls and absorb pressure variations by bending like an automobile tire.

Pumps ( < 5 hp) often can be supported by metal frames instead of inertia blocks, if they can be located on grade where the edges of the concrete floor slab will be entirely separated from the building structure by a continuous joint filled with resilient material (e.g., polyethylene-wrapped glass fiberboard).

Note: Where piping systems are subject to earthquakes, piping damage due to building movement can be lessened by using flexible connections. Snubbers, or seismic bumpers (shown above), must allow sufficient free movement for normal operations.

Next: Isolation Hangers