AMAZON multi-meters discounts AMAZON oscilloscope discounts

Laggings are enclosures, or wrappings, which are used to isolate noise transmitted through the walls of pipes and ducts. The lagging generally consists of a sound-absorbing layer (or blanket) wrapped on the outside by a heavy, airtight, sound-isolating membrane. The effectiveness of a lagging depends on the surface weight of the outside wrapping and the thickness and sound-absorbing efficiency of the blanket. Lightweight wrappings ( < 1 lb/ft don't effectively reduce noise transmission below 500 Hz. Often reducing noise at the source will be more cost-effective than using extensive lagging treatment. For procedures on selecting laggings, see G. E. Johnson, "to Select Effective Lagging Configurations," Sound and Vibration, April 1977.

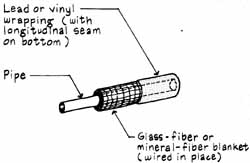

Pipe Lagging

Pipes carrying water at high velocities should be isolated from the building structure and wrapped with dense blanket materials (3 to 18 lb/ft to isolate the water flow noise. Outer wrappings include heavy mastic, lead sheet, loaded- or leaded-vinyl, and composite metal jacket with core of laminated limp materials. An example pipe lagging is shown below. For most situations, a doubling of weight is needed to provide a significant increase in noise reduction (called insertion loss).

Pipe Lagging Details

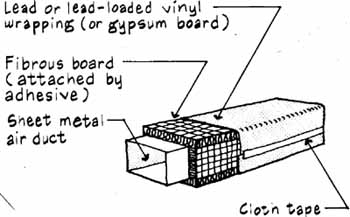

Duct Lagging

Ducts in mechanical spaces and ducts which pass through noisy areas can be penetrated by the surrounding noise energy (called noise break-in). Enclosures of heavy-gauge sheet metal or gypsum board can be used to form a sound-isolating membrane around the ducts. As shown by the illustrations below, provide a wrapping of sound-absorbing material (e.g., glass fiber or mineral fiber) between the air duct and the sound-isolating membrane of the lagging. When duct width exceeds 36 in, support enclosures on underside with battens or other framing elements. To control the transmission of low- frequency noise (< 125 Hz), use sound-isolating plenum or circular ducts in stead of rectangular ducts. For example, at frequencies from 63 to 250 Hz, the transmission loss of sheet metal (without lagging) can be 30 dB or more greater for the stiffer circular ducts than for rectangular or flat oval ducts.

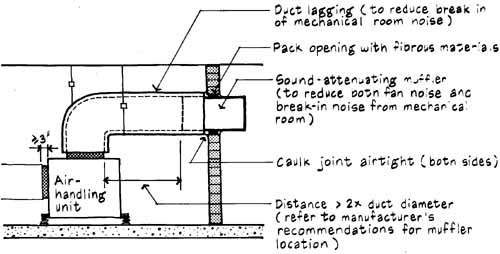

Duct Lagging in Mechanical Room

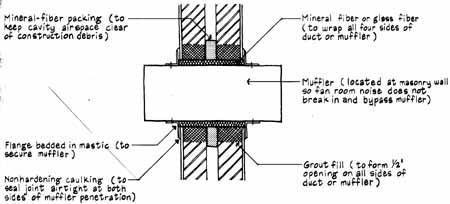

Muffler Installed at Wall of Mechanical Room

Next: Vibration Analysis Graph

Prev: Isolation Hangers