AMAZON multi-meters discounts AMAZON oscilloscope discounts

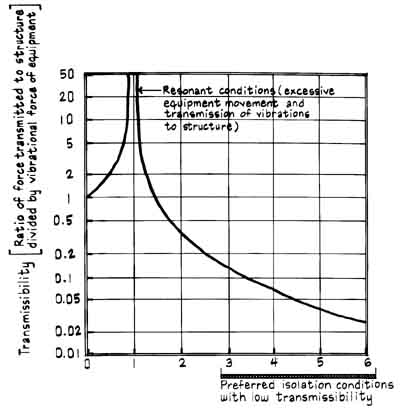

Vibration isolation involves installing vibrating equipment on resilient materials such as ribbed or waffle-shaped neoprene pads, precompressed glass- fiber pads, and steel springs. The goal is to choose an appropriate resilient material that, when loaded, will provide a system natural frequency, or resonant frequency, at least one-third of the lowest driving frequency of the equipment. This kind of support can provide the desired conditions of low transmissibility.

Transmissibility is the ratio of the force transmitted into the supporting structure to the vibrational force of the equipment. Driving frequency f in Hz (or cycles per second) is an operational characteristic of the equipment (e.g., the lowest drive shaft rpm divided by 60) which can be obtained from the equipment specifications or the manufacturer. Natural frequency 1, in Hz is the lowest frequency of vibration that occurs when a mass supported by a resilient material is deflected from its rest position and released. To calculate the natural frequency of a steel spring isolation system on a solid foundation, use the following formula:

fs = 3.13 (sqr. root (1/Y))

where f = natural frequency of isolator (Hz)

Y = spring static deflection (inch)

Next: Natural Frequency and Deflection