AMAZON multi-meters discounts AMAZON oscilloscope discounts

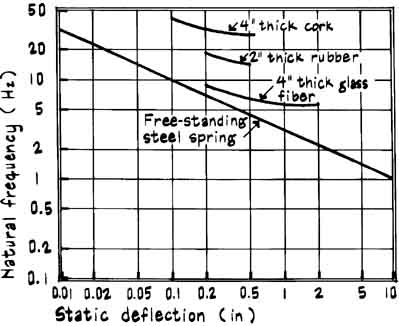

Vibration isolators are fabricated in various shapes from a variety of materials to prevent or reduce energy transfer. The curves below show the natural frequency f, when isolation is provided by free-standing coil steel springs, precompressed glass-fiber pads, rubber or neoprene, and cork. Static deflection is the distance an isolator will compress (or deflect) when the equipment weight is applied to it.

Generally springs are the most resilient of the commonly used isolators because they can provide the largest deflections and therefore can effectively isolate low-frequency vibrations. For lateral stability, the coil diameter of springs should be at least 0.8 times compressed or “working” height H. To isolate both low-frequency vibrations and high-frequency noise, use steel springs which have waffle-shaped or ribbed neoprene (< 50 durometer) attached to the bottom of their base plates. Note that cork gradually compresses under constant load and consequently loses its resilience.

![]()

Rubber; Ribbed Cork; Glass Fiber; Steel Spring

Note: For isolation of vibrations at extremely low frequencies (< 80 Hz), air mounts can be used as an alternative to steel springs. Air mounts are resiliently-reinforced neoprene chambers containing compressed air to support the applied load. A constant supply of dry air is required to compensate for normal mount leakages. Air mounts also can be used to isolate vibration-sensitive equipment, such as electron microscopes and microbalances, from the building structure. The best location for vibration-sensitive equipment is on a ground-supported slab.

Next: Vibration Isolation Design Graph