AMAZON multi-meters discounts AMAZON oscilloscope discounts

A.1 The Problems with Requests to Glass Shops

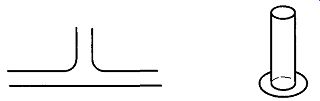

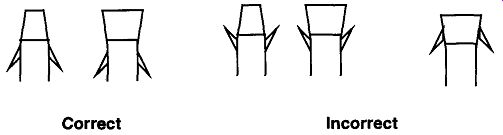

Fig. A.1 Examples of requests to a glass shop.

There are many brilliant men and women who are excellent teachers and scientists, can analyze the most complex data, and can draw the most complex molecules or mathematical equations. Yet, many of these same people cannot communicate the shapes of even simple items on a piece of paper. In addition to this complication, when an object is made of glass, new complications are created. These new problems typically derive from the fact that working with glass is like working with no other material on earth. Thus, the average person will try to rationalize construction with materials they are more familiar with, such as wood or metal. In addition, it is unlikely that this average person will have had the opportunity to learn the parameters and limitations of glassware construction.

[* As a glassblower, I am most familiar with the specific problems encountered with requests to a glass shop. Regardless, these frustrations are shared by all who request custom items for construction.]

I am in no way trying to belittle the problems that machine, wood, or electrical shops have with poorly-made or inadequate drawings. However, sawing, turning, gluing, soldering, drilling, and cutting are common terms that are understood by most people. The terminology of glass is different: Fire-polishing, fusing, blowing open a hole, and spinning a base are as foreign to the average person as the tools used. Because of misunderstandings of the tools and operations used with glass, what a person asks for is often not what they want. Over the years, I've had requests for "drilling a hole in a tube and sticking a tube over the hole in the tube so that material could go several ways" or "welding a flat glass plate on the end of a tube so that it could stand up." In these two examples, what the requestors wanted were a "T" seal and a base to a column, respectively (see Fig. A.1). If I had done exactly what was requested, the costs could have been phenomenal.

A.2 Suggestions for Glassware Requests

Whether you have a glass shop in your facility or send your glassware requests to an outside glass shop, you should limit your requests for what you want and not state how to do it, because this will save you time and money. By simply stating what is wanted, providing necessary dimensions and related construction materials, and avoiding discussions on how to make the item, much time and confusion can be avoided.

The Sketch. Prepare a reasonably accurate sketch. You do not have to be a draftsman or an artist. However, you are not a two-year-old child with a crayon. It is likely that the more time that the glassblower spends on trying to figure out what your drawing is trying to represent, the more you will be charged.

The Measurements. Measurements should preferably be given in centimeters (or millimeters). English measurements are not recommended, and tenths of English measurements are not acceptable.

Tubing Identification. Commercially available tubing is only available in metric sizes. These tubing sizes are shown in Section 3. American-made medium and heavy-wall tubing is made to English measurement dimensions, but are now listed in metric equivalent sizes. For example, 1-in. tubing is listed as 25.4 mm.

Commercially available sizes (both metric and English) of medium and heavy wall tubing are shown in Section 3.

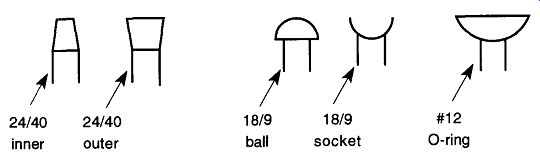

Fig. A.2 Examples of complete joint identification.

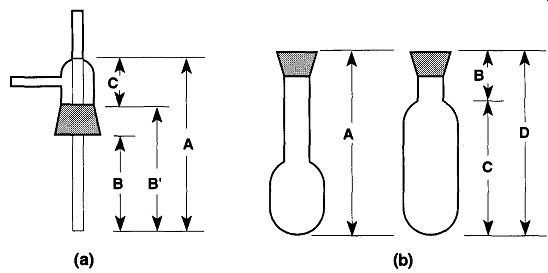

Fig. A.4 Where measurements are made is important.

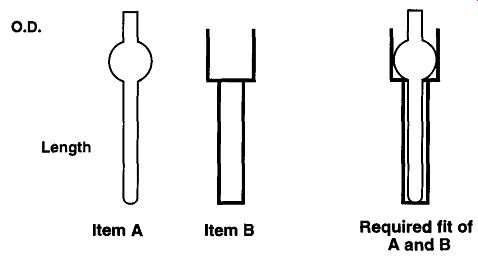

Fig. A.5 If your piece needs to fit within something, say so.

Fig. A.3 Proper orientation and placement of hooks.

Demountable Joint Identification. Joints should be drawn and identified as being either an inner (male) or outer (female) section. Size should be identified as well (see Sec. A.2 and Sec. 3.1.1). Ball-and-socket joints should be equally identified (see Fig. A.2 and Sec. 3.1.2). Because O-ring joints do not have inner and outer sections, only their sizes are required (see Fig. A.2 and Sec. 3.1.3).

In addition, hooks always point away from joints and cannot be attached to joints (see Fig. A.3). The former is obvious because hooks are used to attach springs used to keep pieces together. If hooks are pointed the wrong way, they cannot function. The location of hooks is more subtle because problems can occur if a hook is placed on the outside of an outer joint or too close to ground glass. By placing a hook on or too close to the ground section, it is likely to warp the shape of the ground section, which will cause a poorly fitting, leaky joint.

"But You Never Told Me." Leave nothing understood or assumed unless you are willing to accept whatever is handed back to you. Therefore, leave your name and how (and where) the glassblower may get in touch with you if additional questions should develop. If you are working with (or for) someone else, leave a name and how to get in touch with that person, as well as your own information.

Provide the Right Measurements. Give measurements from specified areas that cannot vary. For example, see Fig. A.4(a), where the length of the cold trap's internal tube is ambiguous by the A measurement because C can vary extensively. On the other hand, the measurement from the ground area of the joint to the end of the inside tube is specific. The B (or B') measurement is preferred.

Provide measurements when a change occurs, such as the seal of one size tubing to another [see Fig. A.4(b)]. The length of the internal tube of the cold trap is ambiguous with the A measurement because the location of B and C can vary extensively. Two preferred measurements would be either B and C, or " and D.

Do Not Make Your Primary Drawing in 3-D. Most of these types of drawings are incomprehensible or confusing, and it is difficult to place measurements on them. An extra sketch in 3-D can sometimes be helpful.

Accuracy. Most glasswork is done within an accuracy of ±1.5 mm (l/16th of an inch). If you require greater accuracy, say so. Similarly, if the glassware fits into some other device, or some other device fits into the glassware, say so. For an example, see Fig. A.5. If item A is ordered, and it is required to fit into item B, it is important to provide the following specifications of item A to the glassblower:

1) The maximum O.D. of the (lower) tube

2) The minimum length of the (lower) tube

3) The maximum O.D. of the ball

Whenever possible, provide item B to the glassblower so that he or she can test to see of the item fits before it is delivered.

Listen to Any Suggestions from the Glassblower. He or she knows what glass can do (and how to do it) and cannot do (and how to avoid it). In addition, he or she makes and often repairs items (perhaps similar to what you want) every day.

Prev. | Next