By E. Stanley Busby, Jr., Engineer, Ampex Corporation

Industrial controls and TV broadcasting equipment often contain circuits that convert analog signals to digital signals, or digital to analog. Such interfaces have made noise-free digital audiotape recorders possible. In the future, improved versions might be the answer for digital video. An experienced design engineer describes the general operation of some circuits that digitize low-frequency signals.

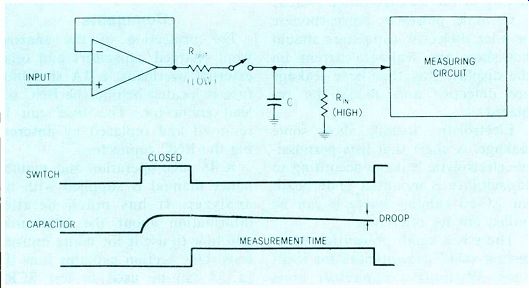

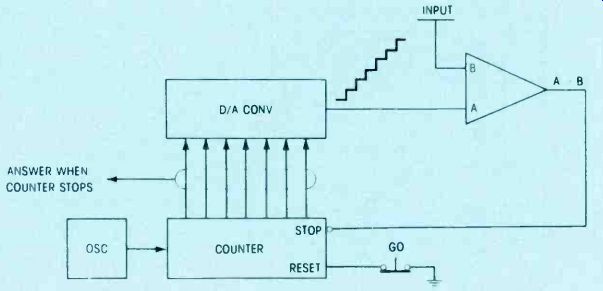

------- Figure 1 -- A dc voltage can be measured or digitized by

a sample-and-hold action. The instantaneous value of an ac signal also

can be determined by a similar method; however, the sampling time and

the holding time must be selected carefully.

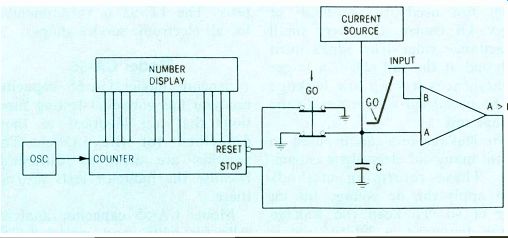

Figure 2 Some digital multimeters measure an unknown dc voltage by counting

the time required to charge a capacitor until its voltage equals the

unknown.

Many digital meters indirectly measure dc voltage by counting the time required for an R/C circuit to reach a certain level as it charges or discharges. This counting and displaying operation is repeated over and over, usually several times per second.

The important word in the previous paragraph is "counting." A nonvarying dc voltage is easily measured by the counting method.

A dependable and accurate reading usually can be obtained by the first or second timing count. Each counting period requires perhaps a quarter to a half second. Measuring the average amplitude of ac voltages is not much more difficult.

The ac is changed to dc, a correction factor is added, and the resulting dc is measured. However, conversion of an ac signal waveform to digital for processing or storage, followed by conversion back to the original analog waveform, is more difficult.

One of the problem areas concerns the length of each individual measurement.

Low-repetition-rate signals (such as industrial-control signals or audio) require careful matching of the duration of each measurement versus the repetition of the signal.

When the time between measurements (or sampling) is too long for the conditions, some part of the waveform will be missing. For example, a sine wave might have segments missing between each measurement.

Also, a measurement time that's too long can allow several repetitions of the waveform to occur, thus changing several sine waves into a straight line.

These two timing relationships must be optimized for best results.

For example, if a sine wave is converted from analog to digital, processed or stored, and then is finally converted from digital to analog, the output waveform should be the same as the original input.

These same precautions apply to digitized video signals.

Several preliminary concepts and a few alternate methods of digitizing ac and varying-dc signals are examined next.

Sample and hold

Figure 1 shows how an electrical signal can be made to hold still while being measured. The procedure goes: close the switch long enough for the capacitor to charge up, open the switch to prevent further change, then measure the voltage across the capacitor.

How fast to repeat the measurement? If a sampling frequency of less than double the highest signal frequency is used, the sampling lower sideband is inside the signal bandwidth. The resulting distortion is heard as a birdie, is seen on TV as moire, and is called an aliasing component by digital engineers.

Theoretically, a brick wall filter having an infinitely steep cut-off (that eliminates all modulating frequencies above half the sampling rate) could permit sampling at exactly twice the signal bandwidth. However, a brick-wall filter is not possible, and so the sampling rate always is chosen to be faster than twice the signal bandwidth. In systems with analog input, digital in the middle, and analog output, bandwidth-restricting filters are used before and after digitization.

Single ramp A/D

Probably the most simple method of converting a voltage to a number (analog-to-digital or A/D) is the indirect method used in most digital voltmeters. Figure 2 shows one elementary approach. To measure, a short circuit is removed from the capacitor, and at the same time, a counter (usually a BCD counter in bench instruments) is started from zero. The capacitor charges linearly until its voltage exceeds the voltage to be measured.

The counter is then stopped and its contents displayed.

This requires that the current source, capacitor, and counting frequency have good long-term stability. There are a number of schemes used to reduce these stringent demands, some of them ramping the capacitor up and down as many as four times. By doing this, the accuracy requirements are concentrated in the reference cur rent source and the instrument can be caused to "zero" itself before each measurement. For digitizing audio or video signals to any usable resolution, this method is too slow.

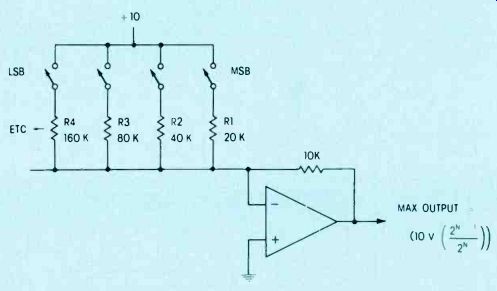

Figure 3 One binary-weighted resistor and switch for each digit can

function as a simple digital-to-analog (D/A) circuit. LSB is the least-significant-bit

and MSB stands for most-significant-bit. Each bit adds its own voltage

to the output.

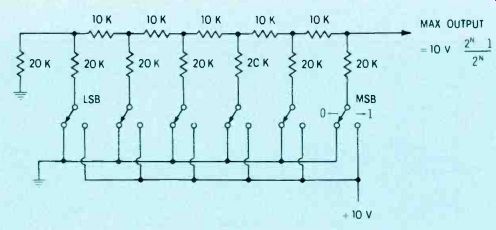

Figure 4 A ladder attenuator can perform the same D/A function as the

binary-weighted circuit of Figure 4, but the smaller spread of resistances

allows better temperature stability.

Figure 5 A/D conversion can be performed by reversing the previous circuits.

A counter starts at zero, and the staircase output is compared to the

unknown voltage. The counting continues until the staircase voltage equals

or exceeds the unknown. When the counter stops, the readout shows the

digital value of the unknown voltage.

Start at the output

A/D conversion is often accomplished with the same circuit used to convert a number to a voltage (digital-to-analog or D/A). Figure 3 shows the simplest D/A circuit. R1, when connected, furnishes a current into the amplifier which is responsible for 1/2 full-scale output; R2 is responsible for 1/4 full-scale; R3 for y, and so on.

Digitization

Adding one more resistor doubles the resolution. It has a problem: even with moderate resolution, the resistor values cover an enormous range.

This makes it very difficult to maintain their two-to-one ratio over a range of temperatures, even when they are encapsulated into the same package.

Figure 4 shows how a ladder attenuator can be used. Arranging the resistors into a ladder attenuator (Figure 5) allows D/A operation without temperature drift.

Try it on for size Figure 5 shows how a D/A can be used as an A/D. A counter which starts at zero drives a D/A whose output is compared to the input being measured. The D/A output increases one step at a time.

When it exceeds the input, the counter is stopped and the number read from it. In the worst case (full scale) it is slow, because it must step through each intermediate value in turn.

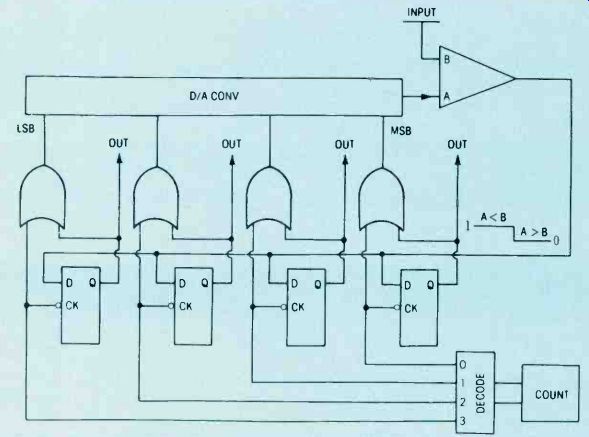

A very popular method is illustrated in Figure 6. The most significant bit (responsible for 1/2 full-scale) is turned on and the D/A output compared with the input. If the D/A output is too much, this bit is turned off and if not is latched on. The next bit (1/2 full-scale) is turned on and tested to see if it should be kept or not. In this way it is only necessary to make N tests for an N bit A/D instead of 2N tests for the counter type. It is adequately fast for digitizing audio frequencies, but not for video.

Figure 6 Operation of the successive-approximation A/D is faster than

the counting type because fewer tests are required. First, the MSB (which

gives half scale) is compared with the unknown voltage. The circuit then

latches or doesn't latch that MSB and tries the next bit, and so on until

a match is obtained and the readout shows the digital value.

Figure 7 Fastest A/D action is obtained by a "one look" circuit

that has one comparator for each analog level. Therefore, 255 comparators

are required for an 8-bit digitizer.

Do it all at once

Figure 7 shows the fastest approach of all. To conserve paper, the illustration is for a 3-bit A/D. One look at the input sample yields an answer. Its problem is that it requires 2N-1 comparators for N bits. An eight-bit digitizer would require 255 comparators. It has been done for digitizing video where time is very short. There are better ways.

When time is short...

Television video is normally sampled at three or four times the subcarrier frequency.

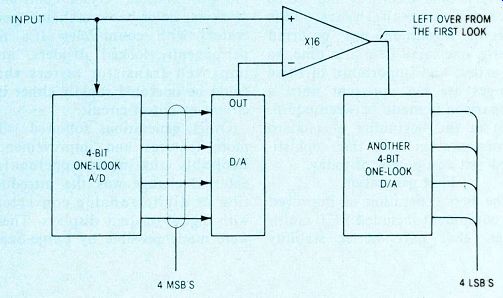

The method used in many digital time-base correctors is shown in Figure 8. Fifteen comparators in a one-look configuration examine the input sample and split out the four most significant bits of the end product. These four bits are applied to a D/A whose output is subtracted from the input sample. The remainder is amplified 16 times and applied to an identical 4-bit one-look A/D to yield the four least significant bits.

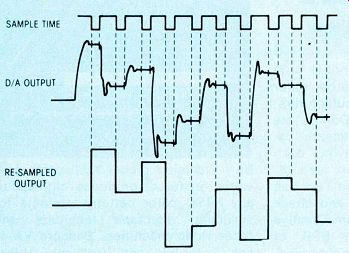

Stepping over the bad D/A circuits take time to settle down after the input number is changed. As their output moves from one value to another, they are likely to produce nasty transients.

The fast component of the transients will be smoothed by the output low-pass filter, but the average of all these ragged edges does not necessarily equal zero and this can produce undesirable effects in the output analog signal. A solution is to re-sample the D/A output as shown in Figure 9, capturing it only after it has become stable. It's like opening the curtains only when the sun is out.

There is a loss of amplitude at high frequencies of the same form as that produced by a playback head gap or an optical scanning slit on a film projector. In practical systems, it is usually less than three dB and easily equalized.

Different Kinds of noise

You may hear the term "quantizing noise." It is not a noise in the sense that it sizzles in the back ground when no one is talking.

Rather it comes from the deliberate limiting of accuracy when converting a signal to a number.

The final output is then only an approximation to the input. A large, spectrally pure input sine wave will emerge as a large sine wave accompanied by some low level trash spread throughout the spectrum. The magnitude of this trash is halved for each added binary bit of resolution. It occurs only in the presence of a signal. It is similar to the asperity noise or modulation noise of an audiotape recording.

Idling noise is more like real noise. If an amplifier somewhere has a little dc offset, its output (with zero input) can present to the A/D converter a voltage midway between step N and step Add to this the inevitable thermal noise in all amplifiers, and the A/D sometimes says N and sometimes says N+1. The output varies accordingly.

The peak amplitude of this garbage is one step. It can be minimized by adding to the input signal a square wave at half of the sampling frequency and having an amplitude of 1/2 step. This tends to concentrate the noise at a frequency which later will be removed by the output low-pass filter. This added signal is called dither.

It would seem that adding more bits of resolution is the answer to all ills. It is, if you can afford it.

For N bits, memory cost is at least proportional to N and the cost of A/D's and D/A's tends to vary as 2N. More accuracy also takes more time.

Analog systems tend to distort large signals, while digital systems mangle weak signals. But there are tricks that allow digital performance to exceed that of analog.

Comments

In industrial situations, digital circuits minimize drift problems and permit elimination of noise from analog control signals. Also, certain kinds of machine controls are practical only in digital form.

The number of digital circuits in industrial equipment will expand greatly.

Digital TV transmitters, tape recorders, and color receivers are coming some year soon. Look for them.

Figure 8 In some TV time-base correctors, the number of comparators

is reduced by digitizing in two steps. First, 15 comparators in a 4-bit

one-look system digitizes the larger amplitudes. Then the second 4-bit

D/A system produces the 4 LSBs.

Figure 9 Over shoots or transients in the output of a D/A system can

be removed by resampling, as shown.

Also see: Test Equipment roundup