By T.R. de VAUX-BALBIRNIE

Staying alive with electrical equipment.

LAST month we discussed electric shock, some first aid procedures and a little of the theory. This time we shall pursue the same topic.

By understanding this, it is more likely that we shall avoid electric shock or reduce its severity in an accident.

Note that those working in industry and education must seek more specific guidance. Also, overseas readers should check their own national regulations since there may be differences in detail.

MAINS SUPPLY

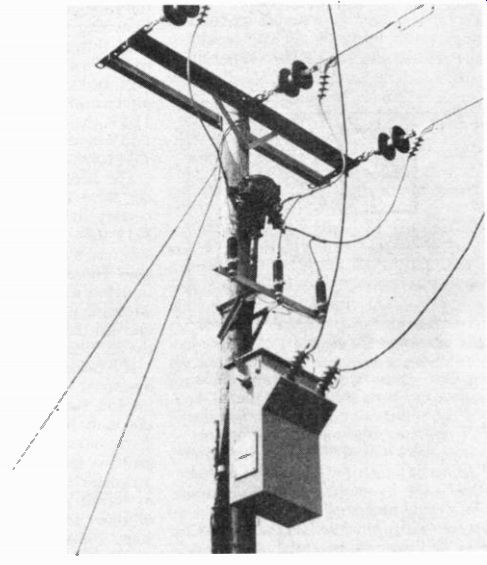

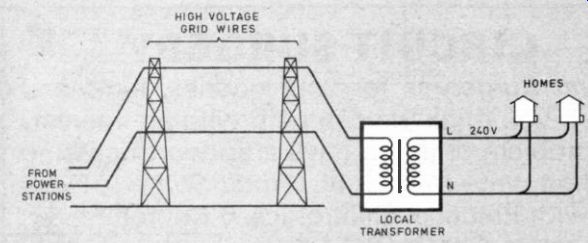

Before proceeding, it is necessary to have at least a simplified knowledge of how mains electricity is supplied to the consumer. The energy is transmitted from the power stations along the National Grid network at very high voltage (up to 400,000 volts--400kV). It arrives at a local transformer (see Fig. la) which may be situated at ground level or may be a pole transformer of the type shown in the photograph opposite.

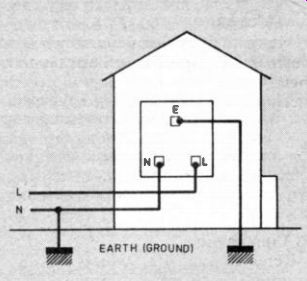

The transformer reduces the voltage to the household working level of 240V and the supply arrives in the house through two wires--Live (L) and Neutral (N). These, together with a third one connected directly to Earth (E), appear at each power socket in the house (see Fig. lb). For technical reasons, the neutral wire is also connected to earth--this is an important point as we shall see presently.

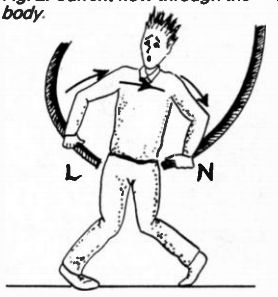

To operate an appliance, a circuit is made by connecting it between the live (L) and neutral (N) wires. For simplicity, we refer to the current entering by the live wire and returning by the neutral one. However, in reality it pulses backwards and forwards through the circuit because the mains supplies alternating current (a.c.). Imagine we have an electric shock situation where a person is holding both live and neutral wires at the same time--one in each hand (see Fig. 2). Current flows through the body completing a circuit.

However, holding both conductors in this way seems rather unlikely and it is difficult to see how it could easily happen by accident. It is more likely that a single bare wire--the live one--will be touched while the feet make contact with the ground. This may also produce an electric shock called an earth-loop shock.

above: Pole mounted local transformer

Fig 1a. Simplified Electricity distribution system.

Fig. 1b. Connections in the house.

Fig. 2 Current flow through the body.

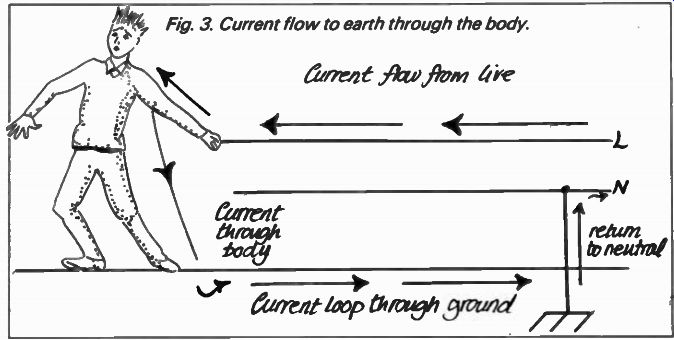

Fig. 3. Current flow to earth through the body.

DOWN TO EARTH

To understand this "loop", refer to Fig. 3. Suppose, due to some fault, the live wire is exposed and a person touches it. Sufficient electrical contact is made with the ground ("earth") through most shoes and, for example, a wooden floor. The earth conducts electricity due to the presence of moisture and various conducting sub stances. There is therefore a circuit formed through the body from live to neutral via the earth as shown by the arrows. Accidental touching of a live conductor can hap pen very easily if wires are pulled free, cut through or sufficiently worn so as to expose the copper beneath the insulation.

The severity of the shock depends on the strength of the current which, as well as the skin contact resistance with the live wire, is also related to the resistance between the person's feet and ground. This, in turn, is influenced by the type of footwear, if any, the material used for the floor and the amount of any moisture present. Note that an accidental brush with the neutral wire will not cause a shock because--no circuit is formed from the live one.

Since touching the live wire is so dangerous, it is essential to distinguish it from the neutral one.

This is done by using a colour code for the insulation. The live lead is usually red in fixed cable (that is, permanent wires) and brown in flexible ones.

The corresponding colors for the neutral are black and blue respectively. In fixed cables, the Earth wire is bare copper and in flexible ones the insulation on the earth wire has green and yellow stripes. It is obviously essential for everyone to follow this code.

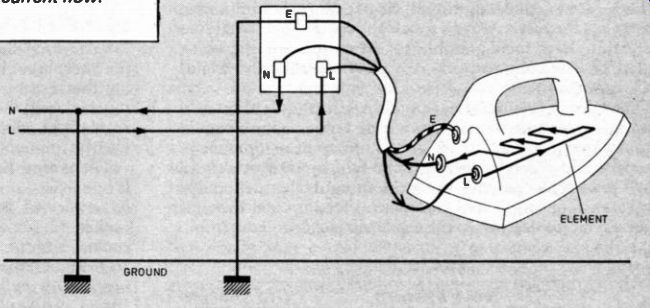

Fig. 4a. Normal current flow.

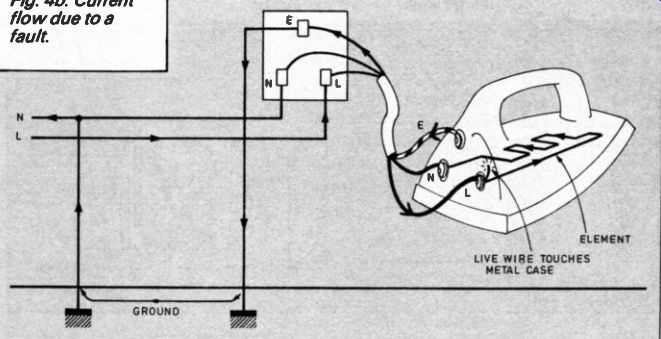

Fig. 4b. Current flow due to a fault.

----Dangerous situation with earth wire disconnected

----Simple test to check appliance earth continuity.

AN INTERESTING CASE

Many pieces of electrical and electronic equipment are housed in a metal case. This may be to provide mechanical strength, electrical screening, to withstand high temperatures or for any other reason where plastic would be unsuitable, it is usual to connect all exposed metalwork to ground via the earth wire mentioned previously using the top pin of the 13A mains plug.

Refer to Fig. 4(a) which shows a familiar piece of equipment--an electric iron--operating from the mains with the element correctly connected between live and neutral and with the case earthed. Suppose the live (L) wire became detached and touched the metal case--see Fig. 4(b). There would now be a circuit formed from the live wire to the metal work, to earth and hence to the neutral of the supply as shown by the arrows.

Since the resistance of this circuit is low, the current would be correspondingly high and blow the fuse in the live wire at the plug or elsewhere. This would isolate the appliance from the mains live feed so if someone touched the case it would be safe.

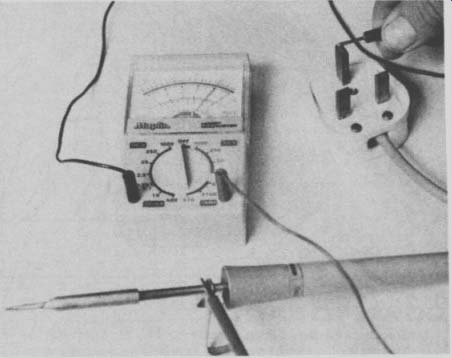

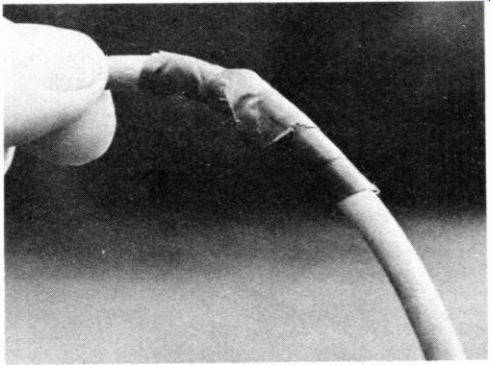

If the earth (E) wire broke loose--perhaps inside the plug (see photograph)--the earth loop would be broken.

In the event of the above fault developing, the fuse would fail to blow and the next person touching the case would receive an earth-loop shock. For this reason, the proper earthing of metal cases should be checked frequently.

This may be done using a multitester set to a low resistance range. With the appliance unplugged from the mains; touch one probe on the earth pin of the plug and the other on a metal part of the appliance (see photograph of this test being carried out on a soldering iron). Practically zero resistance (a fraction of an ohm) should be indicated. This is a very basic test but is better than no testing at all. Note that this does not apply to double insulated appliances (see below).

DOUBLE INSULATION

Certain appliances do not need earthing. Totally plastic cased equipment, for example, where there are no exposed metal parts and certain items which, although having ex posed metal parts, are said to be double-insulated.

Here, because of additional insulation, it is impossible for a detached live wire to touch the metalwork whatever the fault. It is then possible to dispense with the earth wire. This is common practice with certain garden and DIY-type tools.

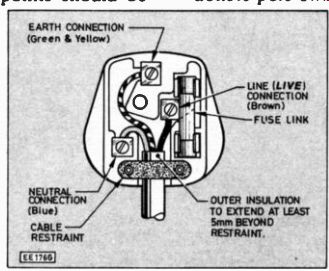

The correct wiring of a 3-pin 13A UK plug is shown in Fig. 5. Table. 1 shows the old wiring colour code mapped against the new one--there is still plenty of equipment in use with old colored wiring although, by now, it should have been replaced with the modern equivalent. If equipment needing only a live and neutral feed is used then, of course, the connection to the earth pin is ignored.

Fig. 5 13A plug wiring.

Table. 1:

New system Old system Live Neutral Earth Brown Blue Green/Yellow Red Black Green

When wiring a plug, the following, points should be especially noted:

• The wires must be connected to the correct terminals.

• Only a small amount of insulation should be removed from the wires.

• When removing insulation, no strands of copper wire should be lost.

• Wire should be securely gripped on the outer sheath. It must not be possible to dislodge it with an accidental pull.

• The correct value of fuse must be fitted

Choosing the correct fuse value will be one of next month's topics.

In an appliance, any on-off switch is placed in the live wire. When switched off, the live feed is therefore disconnected. This is why it is essential when a mains plug is fitted, that the live and neutral wires are connected to the correct terminals.

If the neutral wire is inadvertently connected to the live terminal instead, the switch would appear in the neutral wire. The appliance would still work but, when switched off, the live wire would still be connected--a dangerous situation. Double-pole switches are inherently safer be cause they disconnect both live and neutral wires but they are more expensive.

SAFETY CHECK

Earth-loop shocks are more serious in a bathroom due to the likely combination of bare feet and condensation lowering the resistance, also the taps and pipes which may be touched will be earthed. This is why there are special regulations concerning the use of electrical equipment here.

Use the following information to do a safety check yourself.

There must be no standard power socket in a bathroom.

If one exists, it has been installed by an amateur and must be removed and the circuit isolated. A special shaver socket is allowed--perhaps combined with a small enclosed lamp. The light switch must be cord-operated and situated out of reach--probably on the ceiling. There must be no wall-mounted switches.

Any radiant heater must be situated high enough to prevent accidental touching and, again, the switch must be operated through a cord. Any such heater must be fixed securely to the wall and wired-in permanently--that is, not through a plug and socket.

An electric shower should be provided with a double-pole switch and, in common with other switches, must be ceiling-mounted and cord operated. No appliance may be situated above the bath nor near enough to be touched by a person in the bath.

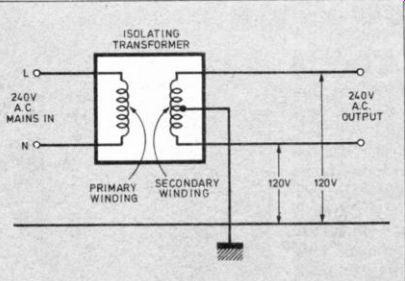

Fig 6. Power isolated transformer wiring.

--------Never repair a damaged lead in this way.

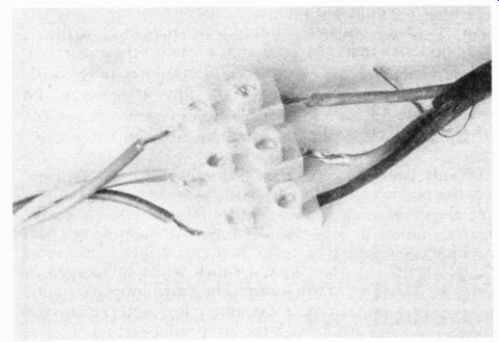

--------Dangerous connections with too much insulation stripped off

Connecting blocks should only be used inside a suitable fixed housing.

---------The plug and socket of a two-core extension must be fitted

in the correct part of the lead.

Obviously, leading a temporary supply into the bathroom by, for ex ample, passing an extension lead under the door is extremely dangerous.

The worst scenario is that of a person receiving a shock while submerged in bath water. The earth-loop resistance here is extremely low and the current through the body will be lethal.

It is not unknown for mains electrical equipment to be placed on a shelf above the bath. It is difficult to see how a person doing this could be so stupid.

IN ISOLATION

We can eliminate the possibility of receiving an earth loop shock by removing the connection between the neutral wire and ground. If a person then touched the live wire--even while making good contact with earth--there would be no circuit and therefore no shock (see Fig. 3). This can be achieved by using an isolating transformer.

An example of a small isolating transformer is the one used in a shaver socket. This has the same number of turns on both primary and secondary windings so the voltages at both input and output are the same--that is, the output voltage will be 240V. A shaver plugged into the outlet operates just as it would if connected direct to the mains. However, there is no longer a link between either output wire and earth (the terms live and neutral do not now apply). Since a shaver socket provides an output at mains voltage, it is still possible to receive a lethal shock if both output terminals are touched at the same time but this is unlikely. However, check the condition of the razor plug and connecting wire regularly just in case it could happen.

More substantial isolating transformers are used to provide large-scale power. Often the secondary winding is centre-tapped to ground (see Fig. 6). Since this winding has two equal sections, only one-half mains voltage exists between either output wire and Earth i.e. 120V. Although it is now possible to receive an earth-loop shock by touching either output wire, the chance of a lethal shock is greatly reduced.

Last month we mentioned that portable tools on a building site are often powered from a 110V supply. This is done by using an isolation transformer having fewer than half the number of turns on the secondary winding compared with the primary. The secondary is wound in two equal sections centre-tapped to earth. This means that the maximum voltage between either output wire and ground is 55 volts and it is thought that, in the event of an earth-loop shock, the current would be too low to present much of a hazard.

HAVING AN EXTENSION

In an ideal world there would be no extension leads but they are sometimes necessary. A short discussion about their safety is therefore worthwhile.

If an extension lead is needed for a double-insulated appliance, this may be of the two-core (live and neutral) only variety and so save costs. The danger is in using it for an appliance which needs an earth connection. On the whole, it is safer to use only three-core extension leads.

For the same reason, it is extremely foolish to mix pieces of two-core and three-core wire to make a long extension lead. If someone removed a plug cover to check that an earth wire existed, on seeing one, they would assume that it was continuous through to the other end. If the live wire in an appliance were to touch the case, the metal work would become live and deliver a shock to the next person handling it.

Ideally, extension leads should not be lengthened but, again, this is sometimes necessary. If it must be done, use proper flex connectors with cable grips and never taped joints. Do not repair sections of insulation removed by abrasion or accidental cutting by using p.v.c. tape or a screw terminal block. The whole length of wire must be replaced or, at least, the offending section removed and a proper connector used.

Sometimes the two parts of a flex connector are used the wrong way round and this is extremely dangerous.

Each connector has a plug and a socket section (see photo graph). It is essential for the socket to be used in the piece of wire which is connected to the mains and the plug part to the wire leading to the appliance. If this precaution is not observed, then with the connector parted and with the lead plugged in to the mains, exposed live pins will exist.

Extension leads should be inspected regularly along their entire length since they are subject to more pulling and abrasion than other forms of wiring. Strain relief clamps in the mains plug and in any connectors must be regularly inspected for tightness. It often happens that wires are accidentally pulled free to expose live conductors. In a damp garden environment this is very dangerous.

The Earth wire in an extension lead should be checked for continuity every so often. To do this, the lead MUST be disconnected from the mains. A multitester set to its lowest resistance range should then be used to measure the resistance of the earth wire from one end to the other.

Depending on the type of extension lead, an earth pin removed from a discarded plug may be used to make the connection at the socket end. Practically zero-resistance (a fraction of an ohm) should be indicated.

Note that in this discussion, we are not concerned with the current rating of the wire. This is equally important and will be looked at in detail next month.

RESIDUAL CURRENT DEVICE [RCD]

The Residual Current Device (RCD) is instrumental in preventing electric shock but--presumably because of its cost and some apathy on the part of householders--is not used as much as it should be. An RCD is often called a Powerbreaker or trip switch.

Contrary to popular belief, an RCD is not an overload cut-out so the correct fuse must still be fitted in the circuit.

An RCD should always be used with extension leads and particularly with appliances being used in damp conditions or in the garden where there is a chance of the wire being cut accidentally.

An RCD is connected between supply and appliance so that the current in both live and neutral wires flows through it. Inside is a circuit which compares these currents. Normally they are the same (that is, current in equals current out) and there is no further effect. If someone touches a bare live wire, current will flow through the body to ground. The effect of this is to reduce the current returning through the neutral wire since some is now diverted to earth. This in-balance is detected and relay contacts break the circuit instantly.

Regulations state that the trip current of an RCD shall not exceed 30mA and it should operate in 40ms maxi mum. Although 30mA is regarded as a lethal current, the disconnection time is too short to cause harm. Before the circuit can be re-used, the fault must be corrected and the RCD reset by pressing a button.

RCD's come in various forms. The smallest type re places a standard mains plug but there are also high current ones which can protect a whole building. RCD's occasionally trip for no apparent reason so it is best not to use one where failure of the supply could be disastrous--with a freezer, for example. The test button provided on an RCD should be used regularly to test its action.

Touring caravan mains hook-up supplies must be protected with an RCD. Installing these, or adding to an existing system, must be carried out only by those with a proper knowledge of the regulations. A section of next month's work will be devoted to such caravan electrics.

FAINTING IN COILS

Suppose you arc checking a relay by connecting its coil to a battery. This is a standard test and the armature will move and click confirming that it is working. If you hold the coil terminals between your fingers while you do this, as the battery is removed it is possible to receive a short, sharp shock.

This often confuses people since only a low-voltage (perhaps 9V) battery has been used as a supply. The shock is unlikely to be of any consequence--it occurs only for a very short time and is confined to the fingers but an explanation is in order.

When the battery is connected, a magnetic field is set up in the iron core on which the coil is wound. This causes the armature to be attracted and the contacts operate.

When the battery is disconnected, the magnetic field collapses very quickly.

This sets up a high reverse voltage (that is, in reverse compared with the battery supply) and this may be sufficient to cause a shock. To avoid it, never hold both coil connections when you test a relay.

Any coils of wire, especially when wound on an iron core to enhance the magnetic effect, can cause similar shocks.

For this reason, it is unwise to experiment with transformers by connecting a battery while holding any terminals between the fingers. Some very nasty shocks can be delivered this way and there may be a stepping-up effect too.

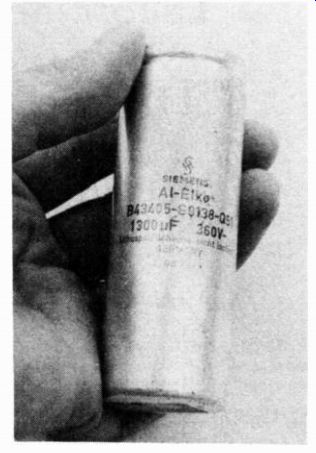

-------- A high voltage capacitor can store a dangerous charge.

CAPACITORS

Electronics enthusiasts should beware of another source of electric shock which may occur even when equipment has been switched off. This is the energy stored in a capacitor.

When a capacitor is connected to a d.c. supply, it will charge up until the voltage across its terminals matches that of the supply. It follows that a charged capacitor can deliver a shock similar to that which would have occurred had the victim touched the supply terminals direct. Real danger exists when a capacitor charges up to more than 25V or so.

In commercial equipment, a high-value resistor is usually connected between the terminals of a capacitor so that when the appliance is switched off, it gradually discharges.

However, this cannot be relied on. It is best to check the voltage across the terminals of any suspect capacitor cautiously using a multitester set to an appropriate (or higher) voltage range. If it is charged to a dangerously high voltage it is best left to self-discharge--check again later.

Some people discharge capacitors by bridging the terminals with an insulated-handled screwdriver (this is not recommended as it is dangerous and it can damage the capacitor). With large-value capacitors--and especially where high voltages are involved--the effect can be very violent. This is because the amount of energy involved is quite high.

The resistance of the circuit is very low, so the current will be enormous--thousands of amps for a short while.

This can cause a flash and melt off pieces of screwdriver. It has been known for pieces of molten metal to cause eye injury.

Problems usually occur with old valve-type equipment where the mains voltage is frequently stepped up to around 350V. Experimenting with such equipment can be very dangerous unless it is unplugged from the mains and any smoothing capacitors allowed to discharge first.

That's all for this month. Next time we shall begin by looking at electrical installations in touring caravans and continue with a discussion of the other dangers of electricity--Overheating and Fire.

(adapted from: Everyday Practical Electronics, Jan. 1994)