Advantages of using programmable electronic controllers in industrial plants are discussed.

By Larry Thompson, Struthers-Dunn Corp.

Ten years ago, most plant personnel regarded the programmable controller (PC) as an alien in industrial control. Too delicate. Too expensive. Too complicated. Takes an electronic wizard to maintain. These comments typify many an initial reaction.

But today, controllers have overwhelmingly earned their place in numerous applications in many industries including the chemical, food, rubber, metals, plastics, lumber, electrical and electronic, petroleum, paper, automotive, textile and power fields. Many have run for seven or eight years without a single failure.

In fact, the question most frequently asked today isn't, "Will they work?" but rather "Where else in our plant does the PC make sense, and how can I get more capability out of it?" The answer depends on what you want.

One surprising thing about the rapid increase PCs have made in the controller field is that the programmable controller usually is not specified mainly for its programmability. Often the decision is made because of other benefits. It's possible that modern programmable controllers are misnamed.

Important controller features In today's industrial field, what is a typical programmable controller? What jobs can one do? When should it be considered for a specific application? A strictly technical definition states that a programmable controller is a solid-state sequencing control device that, once programmed and wired properly to a machine or system, will perform the exact same electrical switching sequence time after time. The strictly technical advantages over relay-type systems lie in:

solid-state reliability which eliminates downtime due to relay failure,

ease and speed of programming and reprogramming--sometimes 10 to 15 minutes versus days of relay wiring,

faster switching which speeds up production, space saving, and

PCs cost less than custom relay panels.

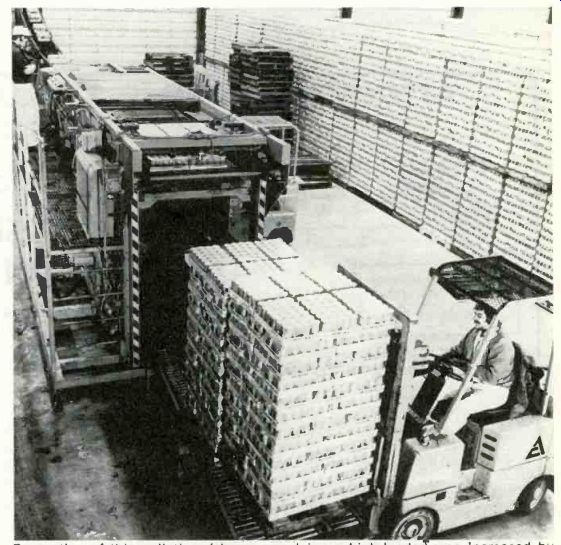

Production of this palletizer (shown supplying a high-loader) was increased by 25% in one Coca Cola plant when an older controller that used relays was re placed by a programmable electronic controller. Faster operation was possible without the relay-cycling time delays. Photos courtesy of Struthers-Dunn.

But this strictly technical recitation is extremely limiting. It misses the programmable controller's real impact. It's like saying a computer can add or subtract faster and store more information. In a real sense, PC's enable plants to manage and monitor the entire production operation better, much like a computer helps executives run the business better.

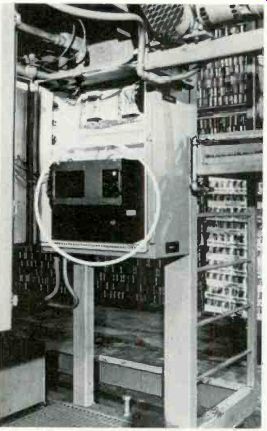

------------ Location of the programmable controller inside the Coca Cola

palletizer is marked by a circle. This controller is much smaller than the

relay unit it replaced, and has no downtime be cause there are no relays to

malfunction.

The reason is that, because it is electronic, the PC inherently lends itself to communicating with a supervisory controller or central computer in ways that no relay system possibly could. Thus, with PCs you not only can control individual machines better, you also can better control the interrelation ship between machines. Put another way, a PC is not limited to operating machinery, it also can help supervise an entire plant.

A quick look around industry will indicate the variety of ways in which industries have capitalized on different aspects of PCs.

To speed production: In a material handling and packaging line, Coca Cola of Houston has increased the capacity of existing equipment 25% by switching from relay control to programmable control. The gain stems from the inherently faster switching that is possible in solid state control. To speed up the relay control would have started a lot of relay races, because the required sequencing rate would have exceeded the response speed of traditional relays.

To speed changeover: At S&S Corrugated Paper Machinery, the new line of box-making machines (essentially a sequencing assembly machine) has shifted from producing one type box to another in a matter of 15 minutes instead of hours. The reason: PCs replaced relay panels in the control section.

Although the number of I/Os (or control steps, in effect) didn't seem large enough to justify PCs on an initial cost basis, the fast changeover capability in itself made the switch worthwhile. In effect, the PCs helped S&S create a new breed of box-making machine, the quick change machine.

In a wider variety of high-production equipment in many plants, it might have been unthinkable to try to change a line over to run another kind of product. Now it's being done in a variety of industries, and creating entire new businesses and product options.

With PCs, changeover to an entire new sequence simply involves switching program cards or chips.

The old chip or card can be stored for the next time the job is run.

New programs can be created quickly by any electrical engineer or technician familiar with traditional relay ladder-type of electrical control logic.

To cut capital costs: The more relays required in a control system, the greater the chance that a programmable controller will carry a lower initial cost. The crossover point depends on the type of relays required and the installed cost that is assigned. A few facts will help figure out the economics, though.

Today, PCs cost between $10 and $15 per I/O when into the 16 I/O capacity range or higher. By contrast, the installed cost of relays may vary from $10 to $100 per relay depending on the relay used and the tabor rate you assign, or the control panel builder assigns.

In some cases today, PCs actually carry a lower initial cost than relay systems in controls requiring as few as 16 relays.

It's always important to consider both cost and capacity together.

Reason even if I/Os are equal, PCs can simply do so much more-in speed, reliability, space savings and communicating with other controls for overall supervision.

To gain reliability: It's ironic that plant managers were suspicious about whether PCs would stand up to tough industrial environments when they were first offered as an alternative to the old relay. In reality, PCs have proven to be more reliable, because there are no moving parts to wear out and fail.

Improved reliability, in fact, is one of the main reasons that pipeline companies have, by and large, switched over to PCs for total station control at remote unmanned pumping stations. Usually the closest available maintenance man is a day's drive away. Yet the PCs must control some extremely complicated pumping sequences, re-routings or shuntings, in rain, snow, hot and cold weather, dust and electrical storms. Moreover, many must operate on either REA power or gasoline-driven generators, where even the quality of electrical power is suspect.

Newer programmable controllers have taken an even further step toward reliability and reduced downtime. The Struthers-Dunn Director 4001 PC incorporates fiber optics for remote I/Os to gain immunity from electrical interference in the plant; and a built-in self-diagnostic system to speed the identification of any defective module.

To minimize plant energy peak demand: Many plants are installing PCs to monitor total plant energy demand and supervise this operation to avoid paying premiums for energy or tripping circuit breakers.

John Deere has extended the same idea to the company's steam-plant which generates heat for some processes as well as overall plant power and comfort. The effect has been more energy-efficient startups.

To cut lead times on new custom machinery: Scores of special ma chine builders, and many company plants which prefer to build their own custom machinery for proprietary reasons, have found that PCs cut the lead times for new machinery by 50%. Reason: machine construction can proceed in parallel with control system design rather than serially. No need to design the entire control system first before mechanical assembly. Run-in and debugging time is cut substantially as well, since a control system adjustment can be made in minutes instead of hours of rewiring or relay replacement.

To cut costs of duplicated ma chine control systems: Where many identical production machines that require the same control sequence are to be built, PCs have allowed enormous savings. Reason: once the initial program for the first ma chine is completed, the chips and cards for the rest of the machine controls are duplicated almost as fast as they can be photocopied. By contrast, in duplicating hardwired relay machine controls, each new control box must be built from scratch in a labor-intensive, time consuming process.

To simply have one around: In the engineering departments of many plant operations, a spare PC is likely to be found. It is used to develop programs without tying up production equipment or to keep a relay-based production line running when a relay fails.

This last phenomenon may be the best indication of how far PCs have come in the plant operations scene.

Another indication of how pervasive PCs have become in the industrial control scene is their appearance on the shelves of many electrical distributors and supply houses as stock items. More than 20 distributors in the more highly industrialized sectors of the country now carry some of the lower-cost PCs in stock, and they're reordering.

Which PC? If a PC seems to make sense, which of the more than 200 models is the right one? That depends on the user's needs. The fact is, some are extremely sophisticated and can do more, but are more complex to program and more expensive. At the other end are extremely stripped-down, simple units.

Here are the key points to consider once the needs are defined, and the models that simply won't work are ruled out.

Cost/capacity: Look past dollars per I/O. Many PCs have special functions (i.e. counters, timers, latches, delays, feedback and loops) that may be important for the application. To compare raw cost per I/O is misleading.

Ease of programming: Some PCs need a computer programmer to program. Others are designed so that any technician or electrician familiar with relay ladder language can do the programming. Consider how much reprogramming will be needed before choosing a brand of PC. If it's the kind of application that will almost never need reprogramming, ask the supplier if he'll do the original program.

Ease of maintenance: PCs fail very rarely, because they're solid state. Look into the cost and complexity of troubleshooting and diagnostic work, particularly if a lot of programming will be done. Some newer models have totally self-contained diagnostics that would en able any plant employee to find a bad module and replace it as easily as finding and replacing a burned-out light bulb. By contrast, other models may require a separate piece of electronic diagnostic equipment to do any kind of trouble shooting.

----- A programmable controller was installed in a bakery to prevent excessive

down time of the previous relay unit (from flour and grease). This was a good

solution, although the bakery operation did not require the flexibility and

additional features available from the electronic controller (a Director 3001

from Struthers-Dunn).

Track record in your industry:

This goes for the company as well as the unit. At the rate new PCs are introduced, it would be a mistake to arbitrarily stick only with ones that have proven themselves in similar service: they could be missing an important new feature. Look at the company behind it as well.

Do its engineers have experience in the field and understand the industry? Will it be there when needed? It is important to be sure the company has the resources to back its product and stay in business.

The PC is here to stay in industrial control. It can do much more than improve the operation of machines-it also can provide better operation of the entire plant.

Also see: