An overview of Biomedical Engineering

By Elliott S. Kanter, BA [Mr. Kanter is Director of Biomedical Engineering, Memorial Medical Center, Savannah, GA.]

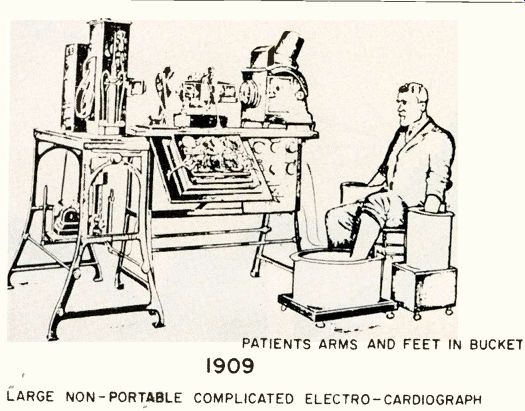

Fig. 1---One of the first examples of biomedical equipment, an early electrocardiograph

represented a first and the beginning of a long and prosperous marriage between

the medical profession and electronics. (Photo courtesy of Hewlett Packard)

New career opportunities appear almost daily for the young, professionally trained electronics technician. In this article the author discusses opportunities in the medical field.

It is just barely dawn and John, a CET is at work. He changes from his street clothes to a loose fitting green uniform, putting shoe covers over his sneakers and a disposable cap over his trim hair.

He enters his 'office', large, well lighted room comfortably maintained at 72° with not less than 50% relative humidity. He then begins his ritual ten minute scrub.

While up to this point, John was like many other technicians throughout the country-up to a point; but, why the need for a ten minute scrub? The reason for the scrub and specialized uniform will become quite apparent as you read this article. John's office is a surgical operating room at a hospital and John is a Biomedical Engineering Technician.

What is a biomedical engineering technician?

What does he do and where?

How does one break into this profession?

Where are training programs located?

Who hires such technicians?

Is there a future as a biomedical engineering technician?

To answer the questions posed here, we will first examine and explain the term biomedical, and give some historical perspective. Don't quit your job yet. The best way to begin or explain this relatively new field is at the beginning, which in this case is the early 1900's.

After centuries of lighting by candle, open flame and oil burning lamps, a young gentleman by the name of Thomas Edison perfected the electric light. This paved the way for valves, or vacuum tubes, which were capable of amplification of minute amounts of electrical energy that were present in the human body. To give you an idea of just how small "minute" is, the human heart provides signals which can be picked up through the skin. However, these signals are in the order of one millivolt (0.001V). Naturally, with the exception of some of our more sophisticated meters and more specifically the newer digital types, we would not be able to discern voltages of this low magnitude.

But, in a manner of speaking, this is putting the horse behind the cart or vice versa.

The wonderful machine we live in is a curious mixture of mechanical, electrical and control circuitry. Each of the body's cells will polarize and de-polarize producing a tiny electrical current which will then travel through a complex cable network of nerves in order to activate control circuitry in the brain. Scientists had been able to prove through a variety of studies, mostly on cadavers (dead bodies), that these things existed. But they were unable, until the advent of electronics in medicine to view and prove these theories on the living body.

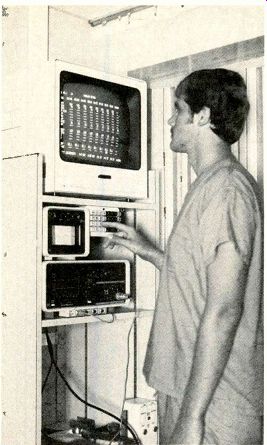

Fig. 2 A scrubbed and suited BMET checks a computer assisted monitor display

prior to its application to a patient. (Photo courtesy Roche-Medical Electronics)

Early devices

Figure 1 is from an old print and shows an early electrocardiograph, a device which takes the minute electrical energy produced by the heart, amplifies it and displays it via a galvanometer on a strip of paper with a heated stylus tracing the actions for all to see. The early EKG machine, was a breakthrough for medicine, and electronics, although its size and the need for buckets of liquid for electrodes did not make it all-too-portable. The key to this "breakthrough" was the fact that a graphic representation of the heart's action in a living breathing body had been achieved; and the strange marriage between electronics and medicine was on!

Fig. 3 A typical state-of-the-art patient monitor capable measuring heart

rate, displaying analog waveforms of direct blood pressure and heart action,

graphic "hard" copy of any parameter in the cabinet as well as cardiac

output and a second direct pressure expressed in CmH2 0. (Photo courtesy Abbott

Medical Electronics)

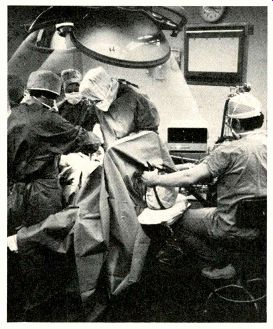

Fig. 4 A compact monitor acts as an additional set of eyes and ears to surgeons

during a complex surgical procedure. During surgery, the monitor constantly

updates the doctors on the heart rate and blood pressure of the anesthetized

patient. (Photo courtesy of Roche Medical Electronics)

The honeymoon has been going on for many, many years now and the grandchildren and great-grandchildren of these early instruments have included the ability to receive radio signal representations of heart rates and other vital signals from astronauts walking the surface of the moon, as well as monitoring patients during surgery. The equipment shown in Figures 2 through 4

represent state of the art monitoring equipment, including computer assisted data interpretations for medical determinations. All in all, from an historical standpoint, biomedical electronic devices have kept pace with the general growth of the industry. What is state-of-the-art in many home entertainment devices is likewise found in medical electronics equipment. The difference being that what your customer might consider a mild irritation on a television set, would prove to be fatal in an open heart operating room.

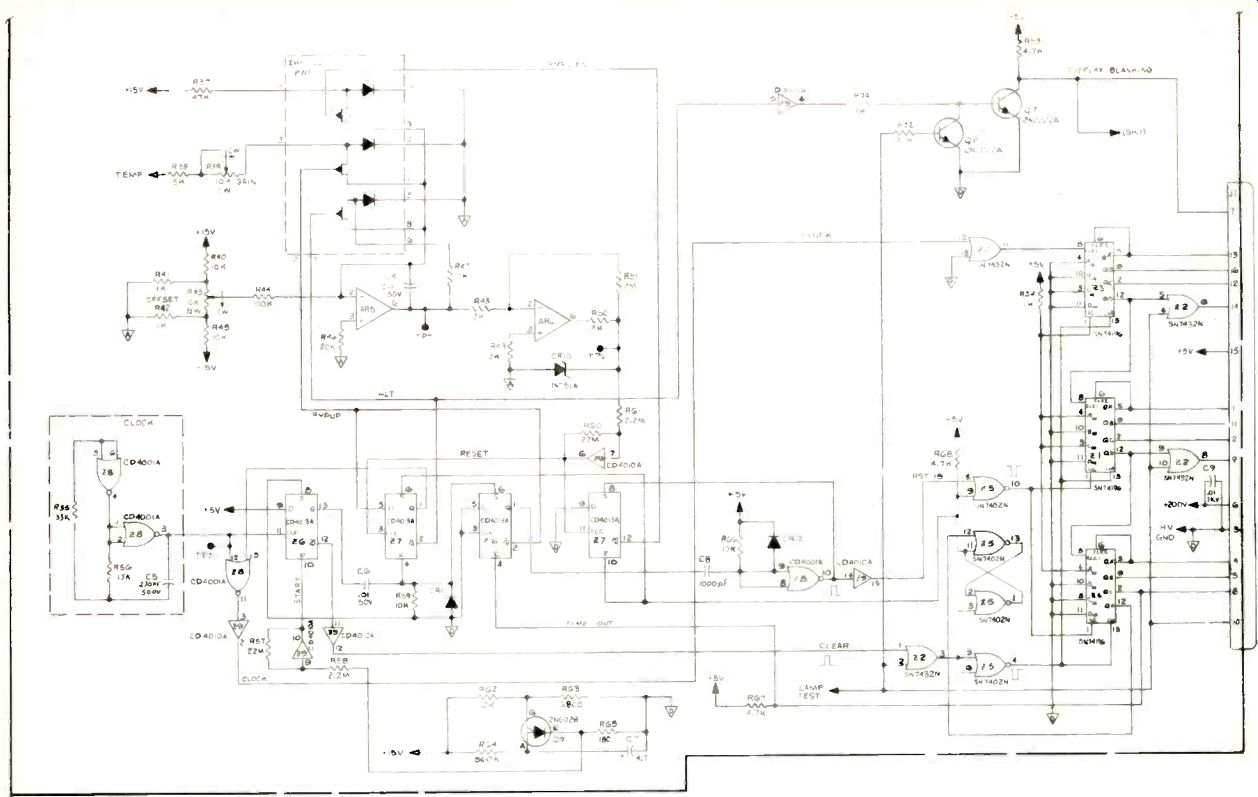

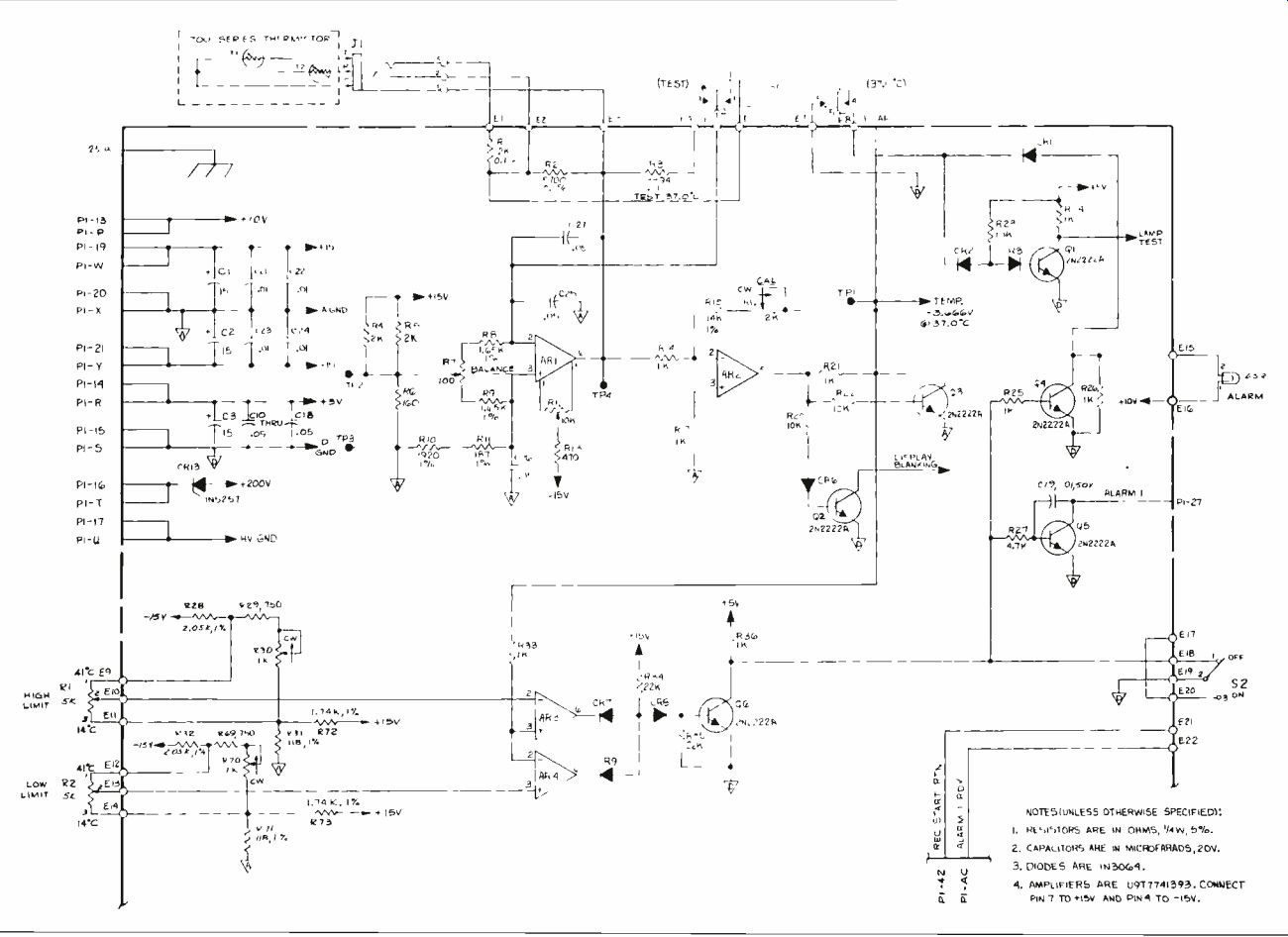

The schematic shown in Figures 5 and 6 represents a digital readout temperature probe with resolution in tenths of a degree and alarm capability. As we examine the circuitry, we find it quite a surprise. We discover it is not complex, but, rather quite straight forward-even simple.

In a single phrase, biomedical equipment or medical electronics equipment encompasses any device which can be used on a person to aid his doctor in providing quality medical care.

It can be a simple suction pump or a complex multi-mode monitor or a sophisticated X-ray machine. It might even include computer-assisted equipment such as the full-body-scanners known as C.A.T.'s (computerized-axial tomography) which look at the entire body in "slices" and provide a computer-enhanced view of possible tumors or blockages. All in all, medical electronics is a fascinating field, one that is growing daily. It is a field open to both men and women and, while some training requirements are specialized, entry level positions are usually readily available.

What does a Bio-Tech do?

A simplified answer to this question would be that he or she would repair, install and maintain equipment either in a hospital, laboratory or doctor's office.

In fact, this question also is combined with another which we posed earlier in this article: Who will hire me? Because these areas are interrelated, we shall examine them collectively. BMET's, as they are known, are found in three areas of industry. The first and most likely place for a majority of new technicians would be on the "staff" of a hospital or medical center. The second area in order of numbers of technicians employed in a service capacity would be factory-direct service engineers or technicians. Also lumped into this category might be the factory assembly personnel. The third and last area would be the independent service agency or specialist who contracts with the hospital, a company or a doctor to provide service in much the same manner that the home entertainment industry service shops would sell a service contract to a TV or stereo retailer.

Fig. 5 Schematic of Abbott Medical Electronics" analog to digital converter

for the TE-4 Temperature Module.

The hospital staff-technician is a full time employee of the medical facility. He is usually assigned to a department and can be under the overall guidance of the chief hospital engineer. At Memorial Medical Center, the department is a separate entity and we cooperate with the general 'plant and engineering' departments to avoid crossovers which can reduce efficiency and increase costs, factors which ultimately must be paid by patients in the form of higher room rates. The department which I head consists of four full time technicians, one of whom is assigned to radiology equipment repair duties. The remaining staff is considered 'generalists' and will work on literally any and all equipment which comes into the shop. Frequently, however, we go to the equipment because it is mounted on a wall or located within a surgical suite.

The center also has a part-time technician whose duties are to assist in repairs to equipment, run patient TV service calls and act as a "gopher." All full time technicians have attended formal electronics schools and supplemented this training with personal home study and attendance at seminars and factory schools. Education in this field is an on-going process which begins on your entrance and will continue until the day you retire.

The obvious advantages of being on a hospital staff are the benefits which would be yours as well as opportunities for continuing education. This can include discounted, or free, medical service for you and your dependents.

Working in the hospital is always going to be diverse and at times quite exciting.

Being assigned to a surgical suite, you might view a child being born, a defect in human heart repaired, or a severed limb re-implanted. Granted, much of your day to day routine will not be this dramatic, but, it would be safe to assume that there is seldom a dull moment.

Factory reps

The factory-direct service-person is employed by one of the countless manufacturers of biomedical equipment. He might be assigned to a field service center, or be on the "road" making on-site repairs. He is both the factory's service-specialist as well as a public-relations person in that he is probably going to be the best or worst-remembered representative of his company for a long time. The technical qualifications of most factory-service personnel are similar to those of the hospital staffer with the exception that they tend to be more specialized.

Frequently the factory service tech might be a specialist on only one portion of his company's line as opposed to the requirement that the hospital staffer be a generalist. Formal electronics training is a must, and some companies require either an associate's degree or a B.S. before you enter their own training program. The obvious differences are that salaries might be higher in private industry and the work could be more specialized. If you like to travel, the field specialist's job is tailor-made for you!

The independent

The last category is that of independent service specialist. This individual may operate his own shop or be part of a combined shared service organization. Basically, he operates in much the same manner that the independent home entertainment repair specialist does. However, he is infinitely more specialized and trained, with a considerable investment in test equipment. Additionally, an insurance premium for third-party liability (malpractice) which approaches the salary of a TV repair technician for an entire year is a necessity due to possible law suits. Being independent, he is his own boss, sets his hours and rates, and must depend on advertising and word of mouth to build his business. He might elect to take on installations and warranty service for a manufacturer who does not have service capabilities in his area. Unlike television service on a warranty-basis, biomedical repairs are at least profitable. Most manufacturers pay $25.00 per hour plus travel time, usually 1/2 the labor rate and/or mileage.

Installations are figured on a per bed basis. The average per bed fee approaches $70.00, according to my industry sources. Taking on these jobs helps the independent build his customer list and frequently will permit him to attend specialized factory training schools which would have been closed to him as an outsider.

Fig. 6 Processor circuitry for the TE-4 Temperature Module.

The obvious disadvantages of the independent service specialist is that he has no assured income sources, at least at first; he must pay for his own liability insurance as well as hospitalization, etc., and he may be limited in what he can service and where. The advantage is he is his own boss. Regardless of which of the three types of service you consider, the field is rewarding both from a monetary as well as an intangible basis. No two days will ever be alike, and one thing's for sure-it will never be boring! There is one catch to whatever area you might elect to join. Hospitals and things related to the medical field happen 24 hours a day, seven days a week. In your local hospital, Christmas is just another day. For that reason, if you join the biomedical field, you will probably be issued, or lease a pager.

This will allow the hospital or your answering service to reach you 24 hours a day! While carrying a pager in some areas can be somewhat of a status symbol, I personally recall sitting in a theater, watching "The Way We Were," about fifteen minutes were left, the show was quiet and the tension was building.

Suddenly, from my belt came a loud series of beeping and a voice literally screaming "... Please call Cook County Hospital-STAT! ..." Needless to say, the tension was broken in the theater, and I received a goodly number of less than friendly stares as I went up the aisle to find a telephone. My date went home with the other couple, and I spent the balance of the night in the intensive care unit trying to get a monitor working again. So, it would be wise to consider the fact that biomedical engineering at any level is not a 9 to 5 job. It requires total commitment on your part, and the cooperation of your family.

Getting started

Basically, we have examined almost all of the questions posed earlier, and can summarize by giving you specifics about how you would go about entering the field, getting training and answering the questions in my somewhat biased manner: is there a future and is it secure? Again, we shall tackle them one by one and interrelate where necessary. Getting the skills is probably easier now than it was, say three years ago. Numerous vocational and junior colleges are offering courses, which can even include internships in local hospitals. If you already have a good solid background in vacuum tube technology, solid state and digital, you will be ahead of the game. All you will have to do is learn to speak "medical," which if you have been looking carefully as you read, part of this article is written in. We don't drip anything, we "infuse it." It's not all that hard to learn and after a while we tend to speak it quite fluently.

You might get strange looks from your friends down at the local parts house when you need a 1.2K 1/2 watt resistor with 1% accuracy, but don't despair, it's part of the medical field's, high degree of reliability and equally high cost.

If you are just finishing a two year electronics program, you might want to contact some of the larger manufacturers of biomedical equipment, they are looking for people just like you for entry level positions which pay considerably more than you'd imagine. In fact, eight dollars an hour is not unusual for entry level, plus a car, expense account, tools, fully paid hospitalization, dental coverage and literally any and every benefit you can dream about, and that's during training! It gets better when you are in the field.

On the other hand, if you haven't got the formal training, there's a good chance that no major company will want you.

You have to have credentials in this field, the more the better. The military offers excellent BMET schools, in all branches, and graduates are assured good jobs when they leave the service. The key word in this field, like any other electronics area today is education! Without it you are no better than "an outsider--looking in." There are possibilities for on-the-job training at some hospitals, but you will have to call around and see. Some hospitals are actually beginning to set up their own schools to train personnel for their immediate needs. Again this is going to vary from location to location and your best source of information will be your local hospitals-try their Personnel Departments and see.

This is not a field for the careless. A person's, maybe one day a loved one's, life may hang in the balance on a device that you have repaired. You can only work one way-as if your own life depended on the results! There is no room in this field for the fly-by-nighters.

He has literally been forced out of the home entertainment field by certification and, likewise, we in the biomedical field have certification: ISCET offers a CET (m) (medical) and the Association for the Advancement of the Medical Instrumentation (AAMI) has a program and exam series leading to a CBET (Certified Biomedical Technician). Many firms, including opportunities available with the VA hospitals, require the CBET as a condition of employment.

All in all it's a growth field and guaranteed not to be dull or bore you.

The question is, are you up to the standards it demands?

(source: Electronic Technician/Dealer, Nov. 1979)