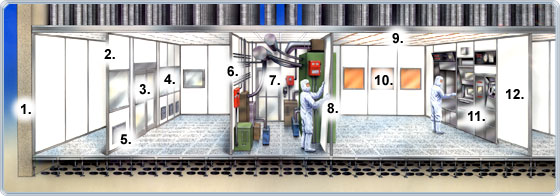

The following cutaway diagram of a modern cleanroom clearly shows its individual components. The description of each component is below the image.

- Furring Wall: a type of wall system that permits quick and easy "skinning" of existing walls or channels.

- Batten Wall: a type of wall system that allows for quick installation with a flush surface on both sides of the wall.

- Electric Sliding Doors: These may be made of aluminum and should be easily install-able into existing cleanroom wall systems.

- Framed Windows: Single or double flush windows; as an option, they may be glazed from stud to stud for full-glass viewing.

- Grille Openings: Return air grilles which can be easily installed into existing wall panels of a clean room.

- Wall Penetrations: Pass thrus, piping and equipment can penetrate wall panels through simple and quick in-the-field modifications.

- Doors: Aluminum rail and stile doors with various hardware options.

- Framed Wall: A type of wall system that provides flush-wall surfaces on the cleanroom side with integrated support on the chase side for piping, conduit and related equipment as may be required for maintenance of the cleanroom.

- Ceiling/Head Track Interface: these are gasketed head tracks that interface with standard grids and flush grids that permits an almost seamless transition.

- Factory Installed Windows: Pre-installed windows with mitered corners for flush glazing with a beveled back permitting simple and quick cleaning.

- Bulkhead

- Elevated Wall Panel: These are panels that may be elevated for side-wall returns. Egg crate or wire mesh can be installed into the studs to hide mechanical plenums.

Previous: Components of a Clean - Room part 1

Also see: Environmental Test Equipment: Cleanrooms