Source: Radio Electronics--Electronic Experimenter's Handbook (1993)

The horizontal output transistor is a critical component in any TV set.

Let's examine some of the procedures involved in measuring its output.

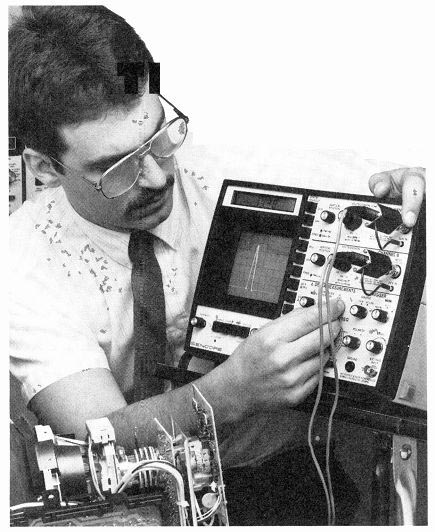

BRIAN PHELPS

FOR ANYONE WHO HAS EVER TRIED TO repair a television with defective signals throughout, or changed a horizontal output transistor only to have it fail once more, we have a technique that can save hours of work and needless replacement of parts. All you have to do is check the "HOT pulse," or the signal at the collector of the horizontal output transistor. Let's see why this waveform is so important, and some key procedures for measuring the signal.

The HOT pulse is important because it performs many functions other than just sweeping the CRT beam horizontally. Some of the key functions of the horizontal output waveform are:

It generates 0.7 amps of horizontal deflection current every 63.5 microseconds.

It generates a 700-1,500 volts peak-to-peak retrace pulse every 63.5 microseconds.

It generates 15,000-30,000 volts DC for the picture tube.

It generates 3,000-8,000 volts DC for the focus circuit.

It delivers "trace-derived" high-current DC power from 16 to 30 volts to operate most circuits.

It delivers "retrace-derived" low-current DC power of 185 to 220 volts.

It provides 6.3 volts for the pulse current of CRT filaments.

It is a critical safety feature.

It provides accurate pulse voltages for the tuner's frequency-synthesis power source.

What to look for The horizontal output pulse supplies operating voltages for the entire TV. It is therefore the most important waveform to check on every TV before and after changing parts. Note: In order to make any of the following measurements, your scope must be capable of measuring, and have input protection up to 2 kilovolts or more. Also, a digital-readout oscilloscope, although not essential to troubleshooting, will make it easier to make the measurements.

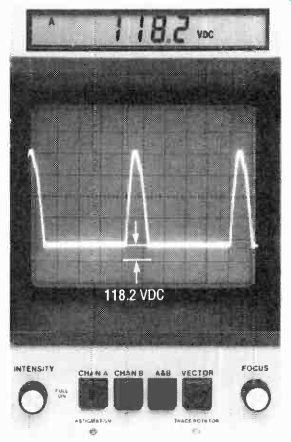

The first thing to check when analyzing the horizontal output pulse is the wave shape; it should look like the one shown in Fig. 1, and be symmetrical in shape during the retrace time. A wide peak at the top of the retrace, or deep saddle conditions, can be caused by an off frequency or glitch in the horizontal transistor base-drive signal. Such problems are often caused by a change in the value of the output-transistor timing capacitors, or by an excessive load on a B+ supply.

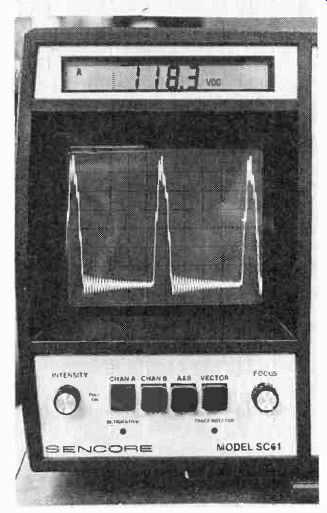

Any excessive ringing or noise is a clear indication of deflection-system problems, such as a cracked integrated high voltage transformer (IHVT) core, or open or shorted IHVT windings. Figure 2 shows an example of a faulty horizontal output. Make sure the waveform looks good be fore you proceed.

Check to see if there are any noise pulses during the trace time. Many of the noise pulses may not be detected when viewing the low-level horizontal wave forms, but they become very noticeable at the collector with an amplitude reaching 1500 volts peak-to-peak. The noise could cause symptoms from drive lines in the video picture to faint noise throughout the TV's circuits.

First measure the DC voltage level of the horizontal waveform.

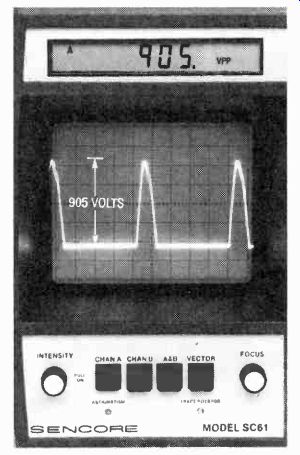

In Figs. 1 and 2 you can see that the digital display shows approximately 118 VDC, which is the regulated B + voltage. Next mea sure the peak-to-peak voltage of the waveform. As you can see from Fig. 3, the display shows 905 volts peak-to-peak.

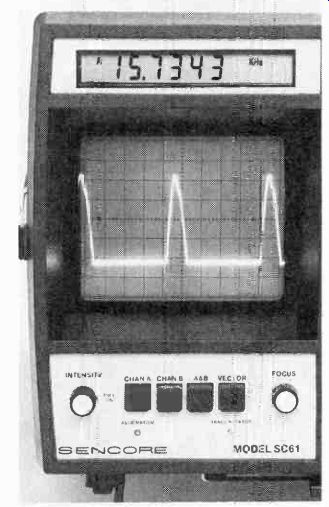

The frequency of the waveform must also be measured. That's as simple as pushing a button on a digital scope. Figure 4 shows the frequency to be 15.7343 kHz. If everything checks out so far, you know the condition of the regulated B + supply, that the TV is not in the shut-down mode, and that the horizontal oscillator is locked to the composite video sync pulse.

FIG. 1-THE WAVE SHAPE should be sym metrical during the pulse retrace time.

FIG. 2--HERE'S AN EXAMPLE of a faulty horizontal output. Make sure the

wave form looks good before you check any thing else.

FIG. 3--THE PEAK-TO-PEAK voltage of the waveform should be between 900

and 1500 volts peak-to-peak. It's shown here as 905 volts peak-to-peak.

FIG. 4--THE FREQUENCY of ;he wave form is important; here it is measured

to be 15.7343 kHz.

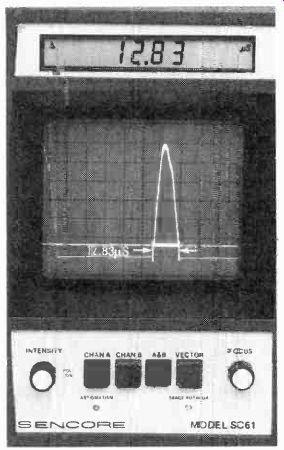

FIG. 5--THE TIME DURATION of the re trace pulse should be between 11

and 14 microseconds; 12.83 microseconds in this case.

The duty cycle of the horizontal transistor output waveform is helpful in troubleshooting. The manufacturer specified that the retrace time should be from 11-14 microseconds, and the trace time should be 49-50 microseconds. Those recommended duty cycles should be observed when troubleshooting.

The time-duration measurement of the retrace pulse should be made between the 10% levels of the waveform. Some digital scopes are equipped to measure portions of a waveform with a delta-time feature. To make that measurement on a digital scope, align the pulse so that the top of it is at the 100% graticule marking and the bottom is at the 0% marking, using the volts/division and calibration knobs. (Make sure your scope will allow accurate digital readings when it is unsealed.) Select the dual-channel mode, couple channel B to ground, and align the trace so it lies on the 10% graticule marking. Select the time-measurement mode, and set the "begin" and "end" knobs so that the intensified trace section is as shown in Fig. 5. The digital display should show between 11 and 14 microseconds. (The display in Fig. 5 shows 12.83 microseconds.) If you measure, say, 9 microseconds, instead of 11-14 microseconds, even though the peak-to-peak value, the DC voltage, the wave shape, and the frequency are correct, the TV will work for awhile, but will more than likely fail at some point. That's because the horizontal output system sees a 35.7% reduction in retrace time-meaning that retrace is faster and generates higher voltage. Therefore, the horizontal output transistor is on longer at full-scan conduction, producing increased heat, increased scan-derived power supply levels, and higher voltages throughout the set. All the circuits are now stressed working at the higher voltages. That, in time, will cause components to fail.

Your scope can also be used to watch for an instantaneous start-up pulse. Simply connect the scope and preset it to view the HOT pulse. Then, watch the CRT as you apply power to the TV's circuitry. If you see a pulse appear and then disappear, your start up circuitry is operating and the set is in the shut-down mode.

If that happens, service the chassis in a "powered-down" condition by either halving the normal B + level separately, or reducing the AC input power to 60-90 VAC. Then monitor the collector of the horizontal output transistor with your scope.

Many underlying performance problems can be uncovered by examining specific characteristics of the "HOT pulse." The wave form shape, symmetry, and duty cycle of horizontal output transistor is critical in diagnosing and troubleshooting electrical malfunctions in your TV set.