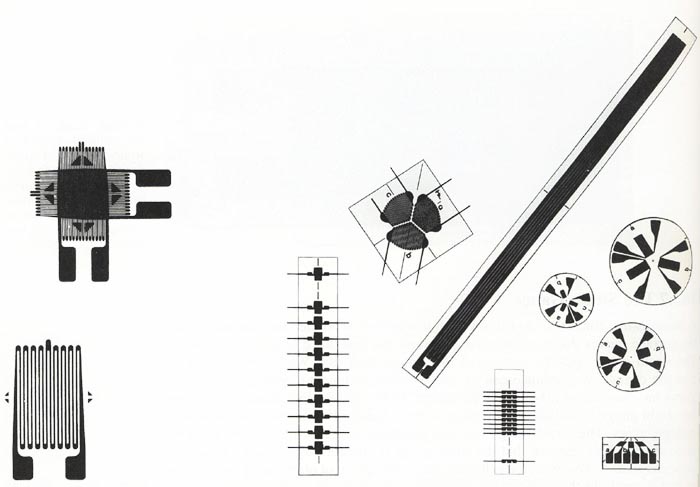

Strain gauges come in a variety of shapes and material that provide more or less change in resistance as they are deformed due to pressure. The types of strain gauge material include piezoresistive or semiconductor gauge, carbon-resistive gauge, bonded-metallic-wire, and foil-resistance gauges. The figures below show examples of the variety of shapes of strain gauges. The most common type of strain gauge is the bonded-wire strain gauge that is less than 1 inch long Figure (a). Figure (b) shows an example of longer bonded-wire strain gauges, which are used to determine the amount of change of a larger surface.

The perpendicular strain gauge is shown in Figure (c). This type of gauge is used to measure strain in two directions such as when a surface is subjected to twisting forces. Figure (d) shows a rosette strain gauge, which is used on surfaces where the stress and strain will concentrate at a point and fan out in any direction.

This type of strain gauge is useful on surfaces that are rounded or curved like the domed surface of a tank. Figure (e) shows a crack propagation gauge and a full-bridge diaphragm strain gauge used to monitor cracks. When a crack is detected in the surface of a vital piece of equipment, this type of strain gauge is mounted directly on the crack and any time the crack changes or enlarges, the amount of change can be monitored by the change in resistance of the strain gauge.

above: (a) Example of the

short bonded-wire strain gauge. (b) Example of a long bonded wire strain

gauge, (c) Example of perpendicular strain gauge. (d) Example of a rosette

strain gauge. (e) Example of a crack propagation gauge and a full-bridge

diaphragm gauge that are used to monitor cracks.

Prev. Page: Strain Gauges | Next Page: Types of Strain Gauges - part 2

Related pages: Load Cells | Flow Meters