(source: Electronics World, Aug. 1963)

----(Left) Teletypewriter is tested with specially built test console. (Right) Checking voltage and current calibration of standard meter.

By GROVER C. GEDNEY & FRANCIS M. WINTERBURG / Federal Electric Corp., Service Associate of ITT

A growing field for qualified electronics technicians and engineers in government, military, and industrial laboratories in this country and all around the world.

ASTRONAUT Walter Schirra's flight was held up for five days because one pressure transducer was out of tolerance by 1 pounds. This error in a simple instrument made necessary a new countdown and the expenditure of many, many thousands of extra dollars.

Accuracy in this case was critical. It is just as critical--if not as dramatic--in countless instances every day. Military operations, industry, and laboratories around the world all require greater and greater degrees of accuracy. The instruments which provide this accuracy could not serve their purpose properly without accurate calibration.

Calibration is the comparison of one instrument with another which has a higher order of accuracy. The ultimate in standards in this country are at the National Bureau of Standards at Washington, D.C. and at Boulder, Colo.

The importance of calibration cannot be overstressed. Research and development, manufacturing, and the installation of complex systems in the field can only be successful if measurements are taken by instruments calibrated to give nearly identical readings during each of these stages. For example, one microvolt prescribed by the design engineer in the laboratory must be read and set to one microvolt by the test technician during field installation.

There are, broadly speaking, three categories of instruments: (1) Test instruments are used to test and set up systems or equipment in the lab, factory, or in the field., and are of medium to high accuracy. (2) On-line instruments are associated with processing plants and other facilities utilizing automated production techniques, and are usually of lower accuracy. (3) Precision -measurement instruments are more unique, due to their specialized applications. These are used in space capsules, missile ranges, built -in test consoles and the like, and require a high degree of accuracy.

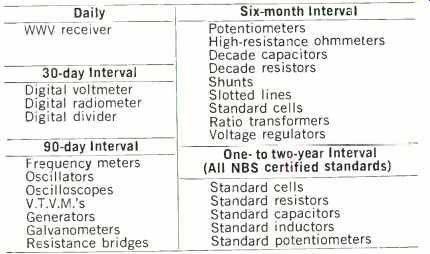

All of these must be calibrated but not at the same intervals. Here are some typical calibration intervals.

While test instrument calibration and repair are closely allied, they require different levels of technical competence.

Standards-lab technicians perform lengthy and very precise calibration of the highest level, usually with secondary standards certified by the National Bureau of Standards.

They must be proficient in the theory of instruments and the mathematical calculations necessary to determine probability of error and long-term reliability. They usually work in a controlled environment where temperature fluctuates not more than a degree, where humidity is held at plus or minus 10 %, and where dust particles are no larger than 10 microns. The work is exacting, requires considerable training and experience. Base salaries range from $6000 to $9500. Highly qualified standards-lab technicians are hard to find.

Test-equipment technicians are called upon to diagnose and repair the many types of faulty and inoperative instruments which are brought to them. Their work is rarely routine, and they must be capable of operating independently, with a minimum of supervision. If gifted with the ability to train others quickly, a test-equipment technician may soon be given the opportunity of assuming supervisory responsibilities. He must respect the mission of the standards lab and establish a confidence in the accuracies to which standard instruments are calibrated for his use.

This category of technician, too, is in relatively short supply and the pay scales are only slightly lower than for the standards-lab group --approximately $5000 to $8000 a year.

As in other branches of electronics, the opportunities for graduate engineers in this particular field of electronics are growing steadily. The demand for specialized training in this area has been great enough for George Washington University to establish a "Center for Measurement Science" which offers an engineering curriculum oriented to the measurement field. Called "metrologists," these engineers develop new measurement criteria and prepare measurement and calibration procedures which the technician may perform. They may be called upon to assist technicians in solving difficult instrument troubleshooting problems, or to determine the probable error of calibration in several instrument systems tied together. Salaries range from $6000 to $15,000 and more.

Background Requirements

Most of the instrumentation we are concerned with at Federal Electric Corporation is in the electrical-electronic field. To qualify for employment in one of our calibration and repair facilities, a man must be a high-school graduate; he must have had one or two years of electronic schooling in a trade service school or engineering college; and three years of experience, at least one of which was in the test instrument field.

Math is extremely important; the more the better. We look for people who have had college physics, college algebra, trigonometry, analytical geometry, statistics, and even calculus. Any math above the high-school level conditions a man's mind to think along technical lines.

With this background, we can train technicians for calibration work on the job. Let's take, for example, a position in our DEW Line Communications and Electronic Equipment Depot.

The man usually begins by working with a more experienced man on the repair and overhaul of meters, or in troubleshooting a piece of test equipment. He then begins to assist in the calibration of test equipment. We have a set of written procedures to follow that becomes routine with experience.

After a month or two of this, he may be ready to become a member of the mobile calibration team. This is a group of five technicians who carry certified instruments from our headquarters in Paramus. N.J. to different areas of the DEW Line Early Warning System in the Arctic, where they calibrate the test equipment that keeps the giant communications and radar system operating at peak efficiency.

After months of mobile team experience, a technician may be qualified to begin work in the Standards Laboratory. He will assist the more experienced men, learn the procedures, and become proficient in the techniques of transfer calibration from NBS standards to our secondary standards.

In choosing a calibration technician for the Early Warning System, a man who is single and willing to travel is preferred to a married man. We do have married men working on the mobile teams and will hire them if well qualified, but the single man is given preference because of having fewer home responsibilities.

These mobile teams travel to Alaska, across Canada at the Arctic Circle, and into Greenland and may be gone for four months at a time. They return to the Communications and Electronic Equipment Depot for three or four weeks to recalibrate their standard instruments and then again return to the DEW Line.

There is adequate opportunity for the married man with a family in the fixed laboratories or facilities. Only on mobile teams staying away from a home base for a considerable period of time is the unmarried man preferred.

Opportunities for Technicians The instrument calibration and repair field is growing and the supply of qualified men is completely inadequate. For example, there are only about 14,000 engineers and technicians who are members of the Instrument Society of America.

The U.S. Air Force, to cite another example, has within the past five years: (1) installed a standards laboratory at Newark, Ohio; (2) built 19 area laboratories; and (3) added 149 precision measurement laboratories.

Within industry, the example of the International Telephone and Telegraph Corporation might be of interest. To assure the accuracy and reliability of its products, ITT Federal Laboratories established in 1956 one of the first large scale standards laboratories to serve an industrial facility.

For several years, the calibration and repair of test instruments have been important services of Federal Electric Corporation.

The instrument technician of today is not confined to the laboratory or factory. If he is well qualified, he enjoys an unprecedented demand for his services.

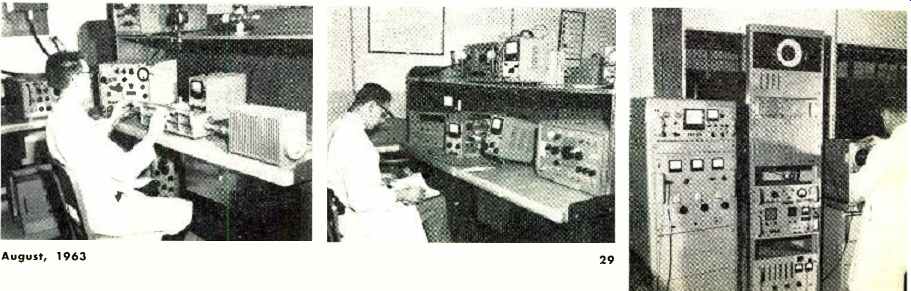

------ (Left) Technician is shown calibrating a u.h.f. signal generator.

(Center) Calibration of a vacuum -tube voltmeter against a standard. (Right)

Checking an oscilloscope time base against a master frequency standard.

ABOUT THE COMPANY

The Federal Electric Corp. operates instrumentation calibration centers in this country and overseas. At Paramus, N.J. there is the Communications and Electronic Equipment Depot established by the Air Force to repair and calibrate our Early Warning System instrumentation. There are 40 people employed there, including three traveling calibration teams made up of five technicians each. Some 20 are employed at an instrumentation center in Albuquerque, N.M. to serve Sandia Corporation, prime contractor for the Atomic Energy Commission, and other users in the Southwest.

The company also operates a standards laboratory at Chateauroux, France, serving the Air Force in Europe, Near and Middle East, and Africa. This group, consisting of 125 people, has technical teams and mobile calibration trailers for on-site checking and repair of electronic equipment. Over 400 are employed by the company in our Pacific Missile Range. These are responsible for the operation and maintenance of the Navy's range instrumentation facilities at Point Arguello and the missile launch facilities in California. Over 1.500 pieces of precision measuring equipment are calibrated and repaired by this facility, which has its own 15-man standards laboratory.