(source: Electronics World, Mar. 1966)

New use for laser permits length measurements having an extremely high order of accuracy.

THE successful measurement of length with a laser has just been completed at the National Bureau of Standards (U.S. Department of Commerce). By the use of a laser beam as an interferometric light source, Bureau scientists have measured the length of a meter bar with an accuracy better than one part in ten million.

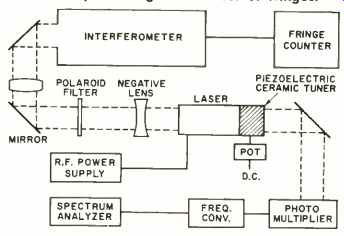

Conventional light sources, such as krypton-86 or mercury-198 lamps, do not permit direct interferometric measurements of lengths greater than a few decimeters. Hence, successive determinations have to be made to measure longer lengths, requiring tedious and time-consuming procedures. A helium-neon laser of improved stability was de signed and built, and the performance of this laser was tested in actual length measurements by means of an automatic fringe-counting interferometer that had been developed at NBS for measuring line standards up to one meter lengths.

The laser was kept in single-mode operation by adjustment of its r.f. power supply and was made to function at or near the center of the red neon spectral line at a wavelength of approximately 632.8 nanometers (6328 A) by tuning the laser cavity.

Since the neon wavelength produced in the laser was not known with sufficient accuracy, it was determined in comparative interferometric measurements. Interference fringe counts were obtained over various portions of a decimeter line standard, first by use of a standard mercury-198 lamp and then with the laser. The neon wavelength of this laser was then calculated by use of the accepted value for the mercury-198 wavelength at 436 nanometers.

-----The meter bar is mounted within the interferometer unit. Its length

is determined by counting the number of fringes.

This calculation showed the neon wavelength to be 632.81983 nm. under standard meteorological conditions, that is, in air at 20°C containing 0.03% carbon dioxide at standard atmospheric pressure and at 1330 N/m^2. (10 mm. of mercury) water-vapor pressure.

The automatic fringe-counting interferometer, with the laser as a light source, was then used to measure the length of the meter bar in terms of this wavelength. As the meter bar inside the interferometer was moved over its en tire length, interference fringes produced by the laser were automatically counted. From the total count of 3,160, 460.33 fringes, or half-wavelengths, the length of the meter bar was determined to be 1.00000098 meters. This length agreed to within 7 parts in 100 million with an independent measurement of 1.00000105 meters for this bar. In addition, measurements of each decimeter graduation on the bar agreed with the independent measurement to better than 0.0000005 meter.

The laser was stable by virtue of its compact and sturdy design. However, it was unstabilized in the sense that no electronic feedback was used to lock its wavelength output automatically to the center of the neon line. Hence, stabilized lasers with single-mode operation will be used in future experiments to eliminate the need for manual adjustment.

Thus, accurate length measurements through the use of a laser may ultimately be routinely performed.

------------------

UNIQUE TEST SET

ONE of the methods used to determine the range and sensitivity of a radar set is to use an r.f. reflective tar get having exact known physical dimensions and radar reflectivity characteristics located at an exact known distance from the radar. This type of testing, known as radar cross-section measurement, is in common use at many of our test ranges today.

Most of these tests are made at special radar test ranges where the calibrated r.f. reflecting metal spheres are placed at various distances from the radar and their return signals measured. In this way, radar sensitivity and range characteristics are evaluated.

Recently, an Air Force Titan III rocket placed in orbit a 75-lb., precisely machined, carefully polished rigid aluminum sphere of unit square meter optical cross section (22.232 inches average radius).

The sphere was ejected from the Titan into a nearly circular orbit 1503 miles up. Making 10 passes each 24 hours, the high-flying test device is presently being used for accurate calibration at a number of radar stations scattered about the world.