A no-compromise circuit with noise gating

This preamplifier design offers a distortion figure of below 0.002%, an overload margin of around 47dB, and a signal-to-noise ratio of about 71 dB for the disc amplifier. A novel noise gate mutes the output when no signal is presented to the disc input and conversely, by using the subsonic information present on record pressings, eliminates the problem of muting low level signals.

This article describes a stereo pre-amplifier that equals or exceeds the performance of many of those available.

The circuit incorporates a novel method of muting the signal path, when the disc input is quiescent, by using a noise gate that never mutes a wanted low-level signal.

Many of the important performance factors, such as signal-to-noise ratio, overload margin, and accuracy of the RIAA equalization, are essentially defined by the design of the disc input circuitry. This therefore merits close attention. The best attainable s/n ratio for a magnetic cartridge feeding a bipolar transistor stage with series feedback is about 71 dB with respect to a 2mV RMS input at 1kHz, after RIAA equalization. This has been clearly demonstrated by Walker 1. The equivalent amplifier stage with shunt feedback gives an inferior noise performance over most of the audio band due to the rise in cartridge source impedance with frequency. This limits the maximum s/n ratio after equalization to about 58dB. These facts represent a limit to what the most advanced disc input stage can achieve.

Overload margin appears to be receiving little attention. The maximum velocities recorded on disc seem to be steadily increasing and this, coupled with improved cartridges, means that very high peak voltages are reaching disc inputs. Several writers have shown that short-term voltages of around 60 to 80mV RMS are possible from modern discs and cartridges, and higher values are to be expected. This implies that to cater for signal maxima, a minimum overload margin of 32dB with respect to 2mV RMS at 1kHz is essential. Obviously a safety factor on top of this is desirable. However, most pre-amplifiers at the top end of the market provide around 35-40 dB only. There are certain honorable exceptions such as the Technics SU9600 control amplifier which achieves an overload margin of 54dB, mainly by the use of a staggeringly high supply of 136V in the disc input amplifier. The Cambridge P50/110 series offers a margin in excess of 60dB by the artifice of providing unity-gain buffering, for correct cartridge loading, but no amplification before the main gain control. This allows the use of an 18V supply rail, but does limit the maximum s/n ratio.

The overload margin of a pre-amplifier is determined by the supply voltage which sets the maximum voltage swing available, and by the amount of amplification that can be backed-off to prevent overload of subsequent stages.

Most pre-amplifiers use a relatively high-gain disc input, amplifier that raises the signal from cartridge level to the nominal operating level in one jump. Low supply voltages are normally used which reduce static dissipation and allow the use of inexpensive semiconductors. The gain control is usually placed late in the signal path to ensure low-noise output at low volume settings. Given these constraints, the overload performance is bound to be mediocre, and in medium-priced equipment the margin rarely exceeds 30dB. If these constraints are rejected, the overload margin of the system can be improved.

Two separate gain controls remove the most difficult compromise, which is the placement of the volume control.

This approach is exemplified in the Radford ZD22 and the Cambridge P60 circuitry. One gain control is placed early in the signal path, preceded by a modest amount of gain. Cartridges of high output can be accommodated by the use of this first control. The second is placed late in the pre-amplifier and is used as a conventional volume control, see Fig. 1.

The other performance criterion which is largely defined by the disc input circuitry is frequency response, as defined by the accuracy of the RIAA equalization. Assuming that the relevant amplifying stage has sufficient open-loop gain to cope with the bass boost required, the accuracy of the equalization depends entirely on the time constants within the feedback loop. Careful design, and the use of close-tolerance components can assure an accurate response to within ±0.2dB from 30Hz to 20kHz.

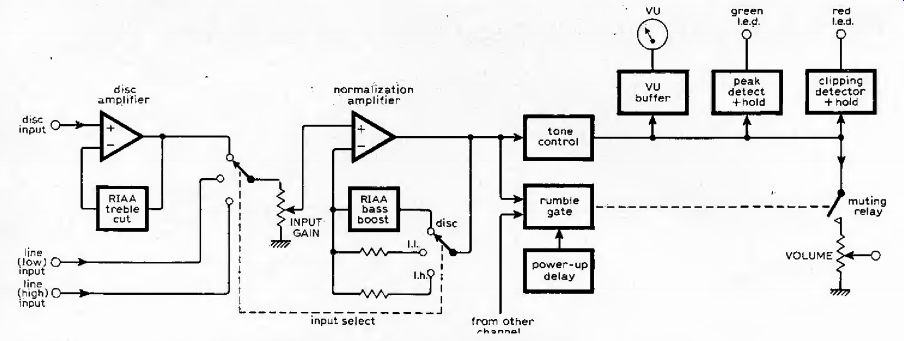

Fig. 1. Block diagram of the complete circuit. Two gain controls are used

in the signal path to allow a substantial increase in overload margin.

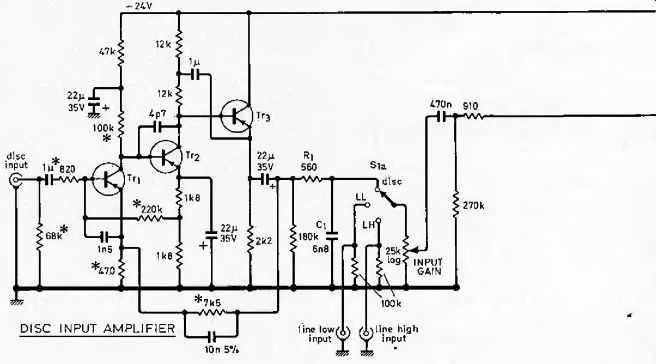

Fig. 2. Circuit diagram of the signal path. Constant-current sources are

biased from a LED/resistor chain for improved thermal stability.

Pre-amplifier distortion seems to have received little attention compared with that generated by power amplifiers, perhaps because the former has traditionally been much lower. However, power amplifiers, with such Sow THD that the residual harmonics can no longer be extracted from the noise at normal listening levels, are now commonplace, particularly with the advent of techniques such as current dumping.

This desirable state of affairs unfortunately does not extend to pre-amps, which in genera] produce detectable distortion at nominal operating levels, usually between 0.02% and 0.2%. In this design the THD at I kHz is less than 0.002% even at 25dB above the nominal operating level of 0 dBm. A Sound Technology 1700A distortion measurement system was used during development.

At this point it is convenient to consider the noise gate principle. When the pre-amplifier is being used for disc reproduction the output from each channel is continuously sampled to determine if a signal is present; if nothing is detected within a specified time interval, dependent on the previous signal levels received, the pre-amplifier is muted by the opening of a reed relay in series with the output signal path. This allows only power amplifier noise to reach the loudspeakers and considerably reduces the perceived noise generated by a quiescent sound system. Noise in the quiescent state is particularly noticeable when headphones are in use. The reed relay is also used to prevent switch-on transients from reaching an external power amplifier. So far this circuit appears to be a fairly conventional noise gate. The crucial difference is that signals from disc that have not been subjected to rumble filtering are always accompanied by very low frequency signals generated by record ripples and small-scale warps. Even disc pressings of the highest quality produce this subsonic information, at a surprisingly high level, partly due to the RIAA bass boosting. The IF component is often less than 20dB below the total program level but this is quite sufficient to keep the pre-amplifier un-muted for the duration of a l.p. side.

The pre-amplifier is un-muted as soon as the stylus touches the disc, and muted about a second after it has been raised from the run-out groove. This delay can be made short because the relative quiet at the start of the run-out groove is sensed and stored. The rumble performance of the record deck is largely irrelevant because virtually all of the subsonic information is generated by disc irregularities.

Audio circuitry

A detailed block diagram of the preamplifier is shown in Fig. 1, and Fig. 2 shows the main signal path. The disc input amplifier uses a configuration made popular by Walker, but the collector load of the second transistor is bootstrapped. This increases the open-loop gain and hence improves the closed-loop distortion performance by a factor of about three to produce less than 0.002% at an output of 6.5V RMS (1kHz). This stage gives a s/n ratio (ref 2mV) of about 70dB and a gain of 15 at 1kHz. This is sufficient to ensure that the noise performance is not degraded by subsequent stages of amplification.

The maximum output of this stage before clipping is about 6.5V RMS and the nominal output is 30mV RMS

Because this is the only stage before the input gain control, these two figures set the overload margin at 47dB. To ensure that this overload margin is maintained at high frequencies, the treble-cut RIAA time-constant is incorporated in the feedback loop. This leads to slightly insufficient cut at frequencies above 10kHz because the gain of the stage cannot fall below unity, and hence fails to maintain the required 6dB/octave fall at the top of the audio spectrum. This is exactly compensated for outside the feedback loop by the low-pass filter R1 C1, which also helps to reject high frequencies above the audio band.

For convenience I have referred to the next stage of the circuit as the normalization amplifier because signals leaving this should be at the nominal operating level of 0-dBm by manipulation of the input gain controls. Separate controls are provided for each channel to allow stereo balance. A later ganged control is used for volume setting and causes no operational inconvenience. In the disc replay mode, the normalization amplifier provides the RIAA bass boost, by the feedback components R1, and C1.

Two line inputs are also provided; line low requiring 30mV and line high 100 mV to give 0 dBm from the normalization stage with the input gain control fully advanced. When these inputs are selected, the feedback networks are altered to adjust the gain and give a flat frequency response. Ultrasonic filters are incorporated to ensure stability and aid RF rejection. Capacitor C3 in the feedback arm reduces the gain to unity at DC for good DC stability. If a fault causes the amplifier output to saturate positively the capacitor is protected by a diode which has no effect on the distortion performance.

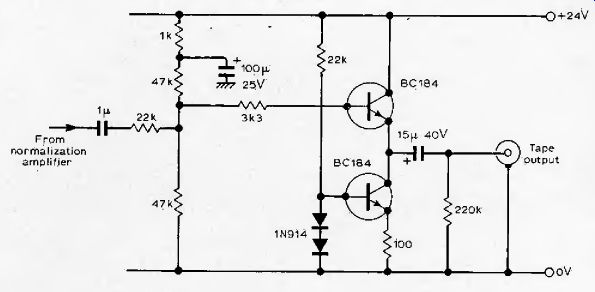

Fig. 3. Tape output circuit. The smallest allowable load impedance for an

undistorted output is about 2.2 k-O. Line inputs of the pre amplifier are

suitable for playback purposes.

The circuitry of the normalization amplifier is complicated because its performance is required to be extremely high. The harmonic distortion is far below 0.002% at the maximum output of 14.5V r.m.s. which is 25dB above nominal operating level. This large amount of preamplifier headroom allows gross preamplifier overload before clipping. The input stage of the amplifier is a differential pair with a constant-current source for good common-mode rejection. The operating currents are optimized for good noise performance, and the output is buffered by an emitter-follower. The main voltage amplifier, Tr9 has a constant-current collector load so that high voltage gain at low distortion can be obtained.

This performance is only possible if the stage has very little loading so it is buffered by the active-load emitter-follower, The various current sources are biased by a LED-resistor chain because the forward voltage drop of an l.e.d, has a negative temperature coefficient that approximates closely to that of a silicon transistor Vfe drop. Hence, this method provides exceptionally stable: DC conditions over a very wide temperature range.

After the normalization stage the signal is applied to a tone-control circuit based on the Baxandall network. The main limitation of the Baxandall system is that the turnover frequency of the treble control is fixed. In contrast, the bass control has a turnover frequency that decreases as the control nears the flat position. This allows a small amount of boost at the. low end of the audio spectrum to correct for transducer shortcomings. The equivalent adjustment at the high end of the treble spectrum is not possible because boost occurs fairly uniformly above the turnover frequency for treble control settings close to flat. In this circuit the treble turnover frequency has been given three switched values which have proved useful in practice. Switch 2 selects the capacitors that determine the turnover point. The maximum boost/cut curves are arranged to shelve gently, in line with current commercial practice, rather than to continue rising or falling outside the audio range. In addition, the coupling capacitor C4 has a significant impedance at 10Hz so that the maximum bass boost curve not only shelves but begins to fall. Full boost gives + 15dB at 30Hz but only + 8dB at 10Hz. The tone control system has a maximum effect of ± 14dB at 50Hz and ±12.5d8 at 10kHz.

The tone-control amplifier uses the same low distortion configuration as the normalization stage, but it is used in a virtual-earth mode. The main difference is that the open-loop gain has been traded for open-loop linearity by increasing the emitter resistor of the main voltage amplifier from 1-k-O to 10k thus increasing local feedback.

Resistor has been increased to 5.6k to maintain appropriate DC conditions.

This modification makes it much easier to compensate for stability in the unity-gain condition that occurs when treble-cut is applied.

Level detection circuitry

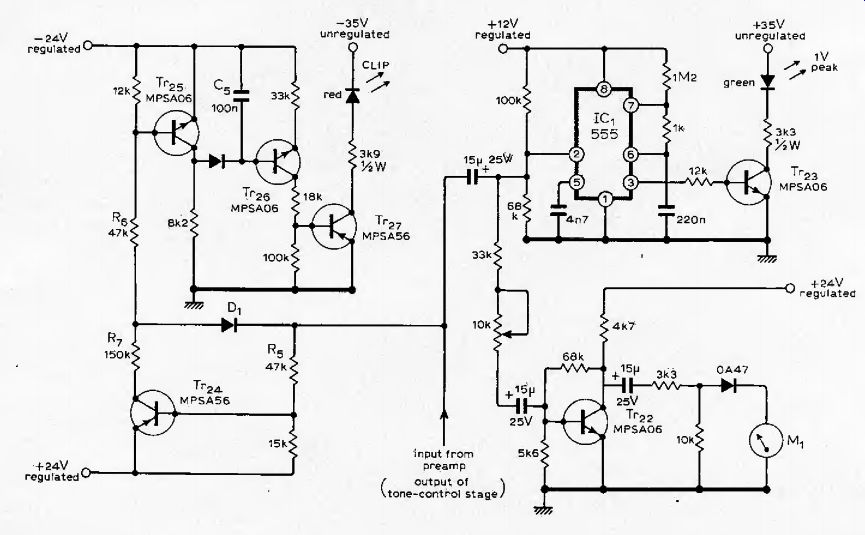

From the tone-control section the signal is fed to the final volume control via the muting reed-relay. Note that this arrangement allows the volume control to load the input of the external power amplifier even when the relay contacts are open, thus minimizing noise. The signal level leaving the tone-control stage is comprehensively monitored by the circuitry shown in Fig.4. Each channel is provided with two peak-detection systems, one lights a green LED for a pre-determined period if the signal level exceeds IV peak, and the other lights a red LED if the tone-control stage is on the verge of clipping. Each channel is also provided with a VU meter driver circuit. Transistor Tr22 forms a simple amplifying stage which also acts as a buffer. Voltage feedback is used to ensure a low-impedance drive for the meter circuitry. The first peak detector is formed by IC) and its associated components. When the voltage at pin 2 goes negative of its quiescent level by one volt, the timer is triggered and the LED turns on for a defined time. The relatively heavy LED current is drawn from an unstabilized supply to avoid inducing transients into any of the stabilized supplies.

The clipping detector continuously monitors the difference in voltage between the tone-control amplifier output and both supply rails. If the instantaneous voltage approaches either rail, this information is held in a peak-storage system. Normally Tr^ and Tr25 conduct continuously but if the junction of D, and Rs approaches the + 24V rail then and hence Tr25 turn off. This allows C5 to charge and turn on Tr26, and Tr27 and hence the LED until the charge on Cg has been drained off through emitter-follower Tr26. If the measured voltage nears the -24Vrail, then D, conducts to pull up the junction of R6 and R7, which once again turns off Tr25In this way both positive and negative approaches to clipping are indicated. This comprehensive level indication does of course add significantly to the task of building and testing the preamplifier. If desired, any or all of the three sections may be omitted.

Noise gate

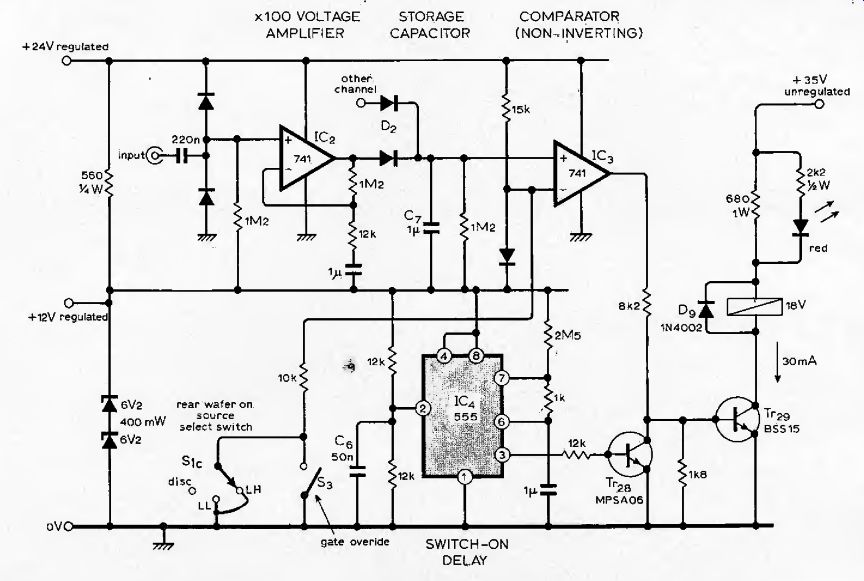

The final section controls the muting reed-relay. At switch-on, the + I2V rail rises rapidly until stabilized by the zener diode. Pin 2 on IC4 is, however, briefly held low by C6, and the 555 is therefore immediately triggered to send pin 3 high. This saturates Tr2g which prevents Tr29 from turning on. At the end of the time delay, pin 3 goes low and relay driver Tr29 is no longer disabled.

The noise gate uses two amplifiers with gains of about 100. These sample both channels at the output of the normalization stage and the inputs are clamped with diodes so that the normalization amplifiers may use their full voltage swing capability without damaging the 741s. Due to their high gain, under normal signal conditions the op-amp outputs move continuously between positive and negative saturation which keeps the storage capacitor C7 fully charged. In the silent passages between I.p. tracks the l.f, signal is not normally of sufficient amplitude to cause saturation but will usually produce at least +3 to +4 volts across C, which gives a large margin of safety against unwanted muting. To facilitate this the response of the amplifiers is deliberately extended below the audio band. When the stylus leaves the record surface and the IF signals cease, C7 slowly discharges until the non-inverting input of comparator IC3 falls below the voltage set on the inverting input.

At this point the 741 switches and its output goes low to cut off the base drive to Tr29, and switch off the relay. When the stylus is replaced on a record, the process takes place in reverse, the main difference being that C7 charges at once due to the low forward impedance of D2.

To prevent the relay sporadically operating when the preamplifier is handling signals presented through the line inputs, an extra wafer on the source-select switch is arranged to override the rumble-sensing circuit, and provide permanent un-mute. This is achieved by pulling the inverting input of comparator IC3 negative of the + 15V rail by the 10 k-O resistor so that even when C7 is fully discharged, IC3 will not switch. In addition, S3 provides a manual override for testing and comparison purposes.

Fig. 4 Level monitoring circuitry. Although three separate circuits are

shown, these may be omitted as required.

Fig. 5. Noise gate and delay switch on circuitry. The noise gate is provided

with an override switch for use with line input signals. The delay switch-on

overrides all of the circuitry.

Amplifier /C2 is repeated for a stereo system.

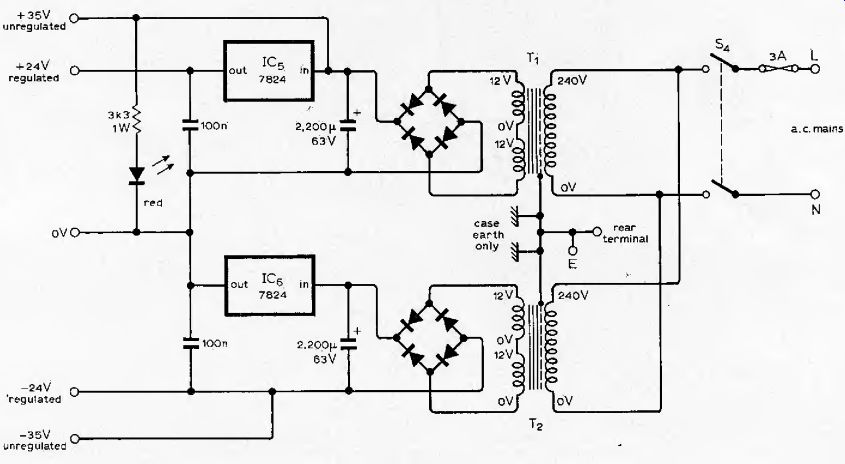

Fig. 6. Power supply. Two regulator ic’s are used which should be mounted

on heat sinks.

The power supply is shown in Fig. 6.

Regulators are used to provide stabilized ±24V rails. The unregulated supply rests at about ±35V. The signal circuitry has been designed to withstand ± 35V appearing on the supply rails, so that even in the unlikely event of both regulators failing, no further destruction will arise. Each regulator i.e. requires about 7 cm^2 of heat sink area.

Physical layout of the preamplifier is no more critical than that of any other piece of audio equipment. In general it is wise to use a layout that places the disc input amplifier as close as possible to its input socket, and as far as possible from the mains transformer. Screened cable should be used between the disc input stage and its input socket, and between the final volume control and the output socket. The earthing requirements are straightforward and the circuit common 0V rail is led from the input sockets through the signal path to the output volume control, and finally to the 0V terminal of the power supply.

This arrangement minimizes the possibility of spurious e.m.f.s arising between stages. The only problem likely to be encountered is the formation of an earth loop when the preamplifier is connected to a power amplifier. Therefore, it may be satisfactory in a permanent installation to have the preamplifier circuitry connected to mains earth only through the signal lead to the power amplifier. The preamplifier case must of course be connected to the mains earth for safety reasons. It is preferable to define the potential of the preamplifier even if the power amplifier is disconnected. In the prototype the 0V rail was connected to the mains earth via a 220 resistor which stops the formation of an earth loop and prevents the signal circuitry from taking up a potential above earth due to leakage currents etc.

Testing is relatively straightforward, providing the preamplifier is constructed and checked stage by stage. Dynamic parameters such as THD are not accurately measurable without expensive test gear, but it has been found in the course of experimentation that if the DC conditions are correct then the various signal stages almost always show the desired a.c. performance, The non-signal circuitry should be relatively simple to fault-find, No problems should be encountered with the noise gate section which has proved to be very reliable throughout a protracted period of testing. The only preamplifier adjustment is for the. VU meter calibration. This should be set to 1V RMS = 0VU, which is completely non-standard, but very useful in terms of the dynamic range of the signal path. For normal operation the input gain controls should be set so that the meter indications do not exceed 0VU, to preserve a safety margin in the later stages. This completes the preamplifier design.

---------------

Component notes

All unmarked diodes are 1N914 or equivalent.

Red bias LEDs are TIL209 or equivalent.

Green bias LEDs are TIL211 or equivalent

Resistors marked with an asterisk should be metal oxide types

Tr, to Tr6 and Tr^ to Tr15 are BCY71

^r

7. 8. 9' 16' 17' 13 2223' 25' 36' 38 are MRS A06Ttio 11¦ 13' 19. so21 ¦ 2427 are MPS A56 Tr9 is 6FX85 or equivalent.

The muting reed relay should be a 2 pole make type with an 1 8V coil, if a different coil voltage is used, the value of the dropper resistor should be adjusted.

The VU meter should have a 1 mA movement.

If an internal diode and series resistor are fitted, the external components should be omitted.

Switch 1 (source select) is a 5 pole 3 way Switch 2 (treble frequency) is a 4 pole 3 way

-------------------

by D. Seif, B.A., Electro-sonic Ltd

-------------------

References

1. Walker, H.P. "Low-noise Audio Amplifiers", Wireless World, May 1972.

2. King, Gordon J. "The Audio Handbook", Newnes-Butterworth, 197S,

3. Heidenstrom, P.N. "Amplifier Overload", Hi-Fi News, December 1974.