| PREV: Features of the Programmable Controller | NEXT: |

AMAZON multi-meters discounts AMAZON oscilloscope discounts

Now that you have a better understanding how the basic PLC operates you are ready to understand more complex operations.

Immediate I/O Updates

In some applications the PLC scan time is too long. One way to lower the scan cycle time to ensure that an input is read more quickly is called an immediate I/O update. The switches that require immediate update must be connected to a module that has special high-speed solid-state devices that can detect the transition of a signal in the nanosecond time frame. The high-speed module has access to a special part of the processor memory. When the processor receives a signal from one of its immediate inputs, it will drop out of its normal scan and immediately service the program logic the switch is controlling. This means that the normal scan cycle for the PLC may be 20 msec, and when the switch that's connected to the high speed module transitions, the processor will acknowledge the request, and interrupt its primary scan to actuate or call the secondary scan called the immediate interrupt scan. The immediate interrupt scan operates independently of the primary scan. This means that the immediate interrupt scan can operate at a much higher speed than the normal scan.

When the input to the immediate interrupt module is transitioned and the signal is sensed, the immediate interrupt scan will execute the logic where the input is used, and write the results of the logic for that line to the correct output as quickly as possible. To ensure the output signal is actuated as quickly as possible, the output module must also be an immediate interrupt output. An example of an immediate interrupt signal is a dud detector for a printing process for soft-drink cans. When soft-drink cans are manufactured, they pass through a high-speed inking process at speeds of over 1000 cans per minute. If one can is not inked correctly, it must be detected as a dud and ejected from the line while the cans pass at high speed. The sensor for the dud detector is connected to an immediate interrupt module. When it identifies a can that's a dud, an immediate interrupt signal is sent to the PLC processor. The PLC processor interrupts its normal scan and activates its immediate scan where the logic is activated and an immediate output signal is produced. The output signal is sent to the immediate interrupt output module that produces the dc signal that's sent to the high-speed solenoid. When the solenoid is energized, it activates a pneumatic high-speed push-off cylinder, which knocks only the dud can off the line as the cans pass by without stopping or slowing the line. Prior to high-speed immediate interrupt modules, the dud detector circuit would be controlled with solid-state logic components instead of a PLC.

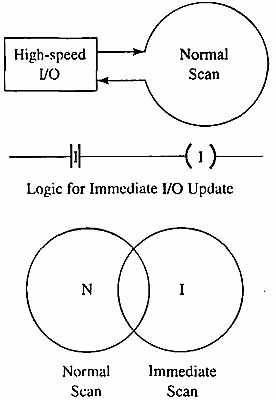

AMAZON multi-meters discounts AMAZON oscilloscope discountsill. 11 below shows an example of the logic in a PLC program that uses the immediate update instruction. This diagram also shows how the immediate update scan cycle is called from the normal scan cycle to high-speed inputs and outputs.

ill.11: Ladder logic for the heat-treating section of the carbon brush manufacturing

system. Logic for Immediate I/O Update. Normal Scan; Immediate Scan.

The Need for High-Speed Inputs and OutputsPrior to the immediate I/O update capability, there were many industrial applications that the PLC was too slow to control. In these cases, traditional solid-state ICs were used. E.g., when a PLC is used for counting functions such as making aluminum beverage cans, the maximum line speed was limited to approximately 600 cans per minute if the scan cycle for the PLC was 10 msec. The immediate I/O update function allows this time to increase by approximately five times. Another way to read inputs and write outputs at higher speeds is to use a module that has a microprocessor specifically dedicated to counting. These specialized modules called high-speed input modules can sense input signals at speeds up to 50 kHz and energize one or two outputs without interacting with the main PLC program. |

| Top of Page | PREV: Features of the Programmable Controller | NEXT: |