| PREV: Example Input and Output Instructions for the SLC 100 | NEXT: Inputs and Outputs for the Carbon Brush Process System |

The best way to understand all of the instructions in the SLC 100 is to study an industrial application that uses a large variety of its instructions. Most programming manuals that come with the PLC explain the instructions without linking them to an actual application. The application in this example will help you understand each instruction.

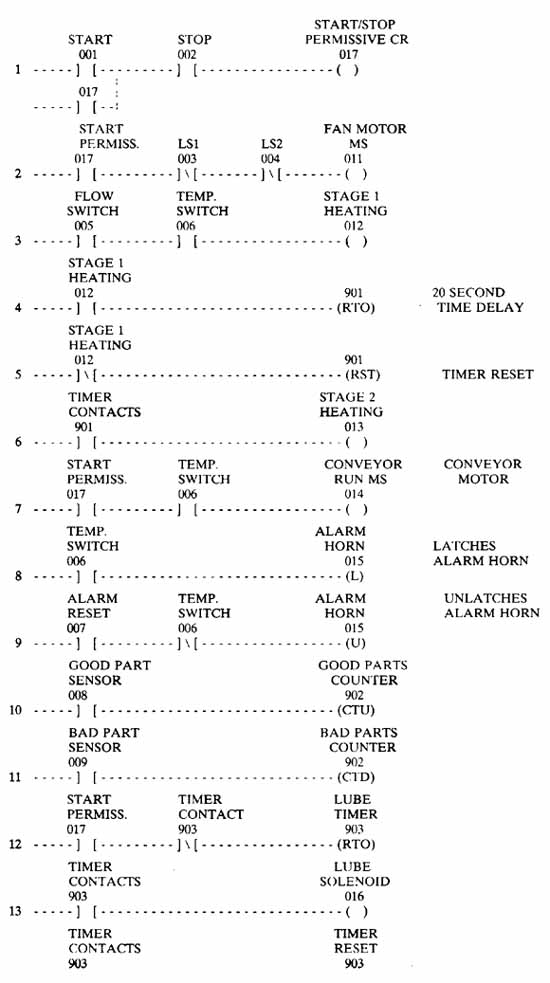

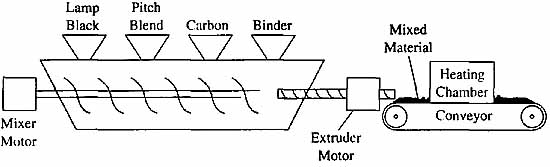

AMAZON multi-meters discounts AMAZON oscilloscope discountsThe batch-mixing and heat-treating system shown in ill. 14 uses contacts, coils, timers, counters, and a sequencer to mix the ingredients to make carbon brushes. One of the largest uses of carbon brushes is in dc motors such as the starter motors in automobiles. After the ingredients are mixed and the brushes are pressed out of an extruder, they have to be sent through a heat-treating process to cure them. A diagram of the process machinery for this application is shown in ill. 15.

ill.14 : Ladder logic for the heat-treating section of the carbon

brush manufacturing system. 20 SECOND TIME DELAY; TIMER RESET; CONVEYOR

MOTOR; LATCHES ALARM HORN; UNLATCHES ALARM HORN

ill.15: Diagram of the mixing and heat-treating equipment

for the carbon brush manufacturing system.

| Top of Page | PREV: Example Input and Output Instructions for the SLC 100 | NEXT: Inputs and Outputs for the Carbon Brush Process System |