AMAZON multi-meters discounts AMAZON oscilloscope discounts

The main drawback to using pneumatic cylinders as actuators is that they don't provide a simple way to stop somewhere between the two extreme positions of fully extended and fully retracted. To correct this problem, robot designers found that stop blocks could be added to the pneumatic cylinder assembly to provide intermediate stops.

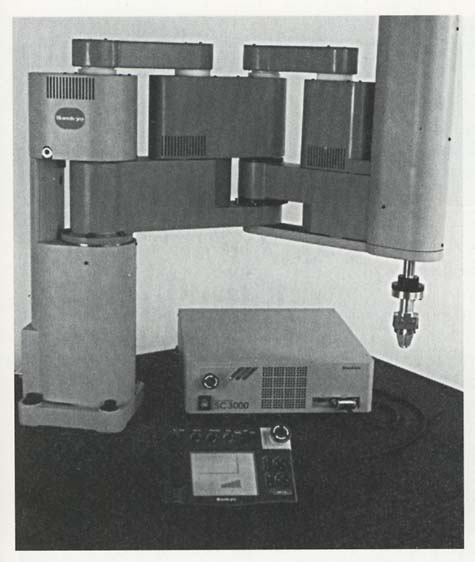

ill. 1 shows a picture of a robot that uses stop blocks. The up/down axis for these robots uses pneumatic cylinders, which allows the cost of this type of robot to be less expensive. Generally when the pneumatic cylinder is used as the actuator, the axis has two points or stops: one at the top of the pneumatic cylinder stroke, and one at the bottom. Stop blocks that are 1 inch (2.54 cm) or 2 inches (5.08 cm) in thickness are added to the cylinder several inches above the bottom of the stroke. When the stop block is activated into position by extending another small pneumatic cylinder, the robot will stop at a point that's 2 in. above the bottom of its stroke, which is also 2 in. above the work surface. This position could be used if the pick-up point for the robot is higher than the drop-off point. If the stop block is retracted, the pneumatic cylinder is allowed to drop all the way to the bottom of its stroke.

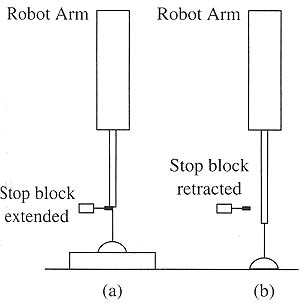

ill. 2a shows an example of the cylinder in the partially down position resting on the stop block to pick up a part from a raised work surface. ill. 2b shows the suction cup resting in the fully down position on the lower surface. Notice that the stop block is retracted to enable the pneumatic cylinder to be lowered to the fully down position. When the stop block is retracted, the suction cup can reach all the way to the bottom of the stroke. In this figure the stop blocks are shown at the bottom of the stroke. Some robots use stop blocks at the bottom of the pneumatic cylinder's stroke. The robot pictured in ill. 1 has its stop block located at the top of its pneumatic cylinder.

Above: ill. 1: A robot that has a pneumatic cylinder

for the up and down axis. The up and down axis uses stop blocks for multiple

positions. The remainder of the axis motion is supplied by servomotors.

Above: ill. 2: (a) Pneumatic cylinder that uses a

stop block to stop suction cup 2 in. above the work surface to pick up

a part. (b) The stop block is retracted so the pneumatic cylinder is extended

all the way to the bottom of its stroke where it touches the work surface.

| Top of Page | PREV: Pneumatic Actuators | NEXT: Comparison of Robot Actuators |