AMAZON multi-meters discounts AMAZON oscilloscope discounts

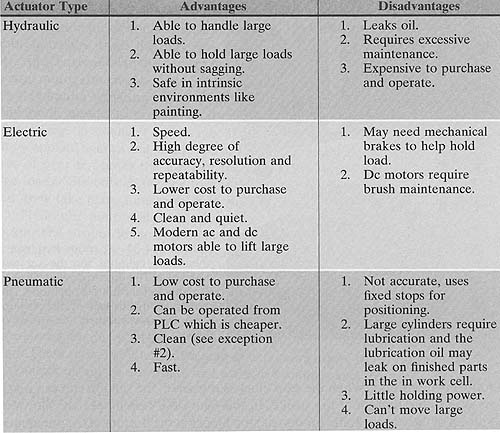

During the 1970s and 1980s more dc motors than ac motors were used on robots because ac variable-frequency drives had not been perfected for larger loads. The DC motors used on robots were mainly permanent magnet motors that required maintenance on their brushes and commutators, and they also were limited to smaller-size payloads. Today brushless servomotors and permanent magnet DC motors are popular on smaller robots that can attain high-speed travel. This is useful in applications where the robot must make multiple movements at high speed, such as inserting components in a printed circuit board. The table in ill. 1 shows a comparison of the advantages and disadvantages of electric, hydraulic, and pneumatic robot actuators.

Above: ill.1: A table that compares electric, hydraulic, and pneumatic robots.

| Top of Page | PREV: Stop Blocks for Pneumatic Robots | NEXT: Input and Output Signals for Industrial Robots |