AMAZON multi-meters discounts AMAZON oscilloscope discounts

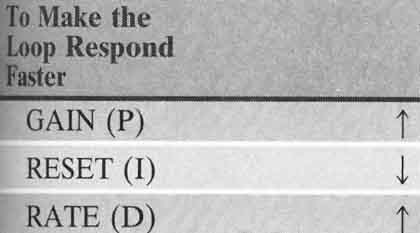

More frequently, adjustments to gain, reset, and rate are made after the system has been running for a while. Changes will need to be made if the system response is too fast or too slow. This type of tuning is very easy to comprehend if one remembers the rules in ill. 1.

Changing gain, reset, and rate is like changing the speed of an automobile while driving. One can slow down by letting off on the accelerator or by stepping on the brakes. Varying amounts of each can achieve the exact same speed. When changing the system response, realize that gain is used to set the first part of the response, and the integral is primarily used to make changes during the remaining cycle. It's important to understand this if, for example, a system is controlling the temperature in an oven, which is brought up to temperature once a week on Monday morning and left to run at the SP for the remainder of the week. Here, the gain would be used when the system was brought up to temperature, and the integral should be used to make adjustments after it's up to temperature.

If the system requires the SP to be continually changed, or if the PV changes significantly, such as when a new batch is processed every hour, the gain will have a much greater effect on the response of the loop.

PREV: Determining

PID Values in Automatic (Closed-Loop) Mode

NEXT: Process

Alarms and Deviation Alarms