AMAZON multi-meters discounts AMAZON oscilloscope discounts

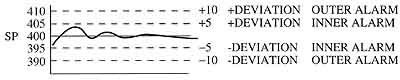

The process and deviation alarms can be set so that two bands of alarm points are used. ill. 1 (below) shows an example of inner and outer alarms for the deviation alarms.

Above: ill. 1 Graph showing two sets of deviation

alarms. The alarm that's closest to the setpoint is called an inner

alarm, and the alarm that's farthest from the setpoint is called an

outer alarm.

This figure shows the inner alarm point for the deviation alarm is set at +/-5°F, (395°F and 405°F) and the outer alarm is set at +/-10°F (390°F and 410°F). A warning light may indicate that the inner alarm point has been exceeded, and the operator can check the system to ensure the controller is trying to bring the process back into the correct operating range. If the condition continues to drive the process beyond the outer deviation point, additional controls may send the product to a holding area to be tested because the process exceeded the standards that are set for acceptable quality. The inner and outer deviation alarms provide a means to ensure that only top-quality products are produced.

The fixed process alarms can also use inner and outer alarm points. This gives the system the ability to warn the operator prior to the outer alarms being exceeded. E.g., the fixed high inner alarms may be set at 550°F and the low inner alarm may be set at 50°F. If the temperature exceeds either of these alarm points, the operator will be warned by an audible or visual alarm so that the system can be checked before it starts to shut down. If the problem continues and the outer alarm point of 600°F or 32°F is exceeded, the system will go into fail-safe shutdown procedure. During the fail-safe shutdown procedure, safety devices will take control of the process equipment and bring the process safely under control. For instance, if the outer high alarm on a heating system tripped, the power to the electric heating coils will be de-energized and an audible alarm such as a warning horn will indicate the system has a serious problem.

PREV: Process Alarms and Deviation Alarms

NEXT: Statistical Process Control