AMAZON multi-meters discounts AMAZON oscilloscope discounts

INTRODUCTION

This handbook serves as a reference on how to be safe around electrical energy. In this section, the consequences of an electrical safety failure related to generation, transmission, distribution, or operation of commercial power are presented from a medical point of view.

As noted in the preface, each year many people are killed or injured by electrical energy.

In the vast majority of these events, the individuals involved never realized how their time on the job might change their lives.

Statistical survey

Numbers give a statistical picture of known electrical injuries and fatalities. The U.S. National Institute of Occupational Safety and Health (NIOSH) has published analyses of the U.S. Department of Labor (DOL) Bureau of Labor Statistics (BLS) electrical incidents data. Cawley and Homce in 2008 found that between 1992 and 2002 in the United States, 3378 people died because of an occupational contact exposure to power frequency electrical energy. During this period, electricity remained the sixth leading cause of injury-related occupational death, with 47 percent of all electrical deaths occurring in construction and 42 percent involving contact with overhead power lines. Nonfatal electrical injuries affected 46,598 employees, with 36 percent reporting contact with electric current of machine, tool, appliance, or light fixture and 34 percent reporting contact with wiring, transformers, or other electrical components.

In a 2003 analysis of 623 detailed fatality reports, Cawley and Homce's research showed that 87 percent of the fatalities occurred with electrical sources of 15,000 V or less, with 32 percent of the fatalities noted during work on 0 to 600 V (Table 1). Overhead power lines were an electrical source in about 40 percent of the deaths, consistent with the researchers' 2008 findings.

AMAZON multi-meters discounts AMAZON oscilloscope discountsFrom 1980 to 1995, among young workers, electrocution was the cause of 12 percent of all workplace deaths and the third leading cause of work-related deaths among 16- and 17-year olds, after motor vehicle deaths and workplace homicide.

====

Table 1 Source Voltages recorded in 623 Occupational Fatality Narratives2

Cases No. of deaths | Source voltages

198 0-600 V

50 480 V

18 440 V

24 277 V

36 220/240 V

42 110/120 V

8% 50 601-5000 V

35% 215 5001-10,000 V

13% 81 10,001-15,000 V

13% 79 Over 15,001 V

====

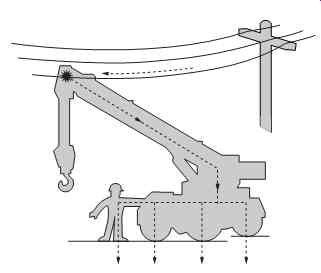

FIG. 1 Overhead power line contact by a construction crane. Worker

electrical exposure to an overhead power line in a construction scenario

with a haul truck contacting an overhead power line. Overhead power lines

account for about 40 percent of U.S. occupational electrical fatalities.

Focusing on electrical fatalities among U.S. construction workers, while comprising about 7 percent of the U.S. workforce, construction workers sustained 47 percent of electrical fatalities. FIG. 1 illustrates possible electrical exposure hazards on a construction work site with a crane truck and overhead power line nearby. In the illustration, electrical current flows from the power line through the truck to contacts between the truck tires and earth ("step potential" hazard) and the truck and worker ("touch potential" hazard) while the worker is standing on the earth.

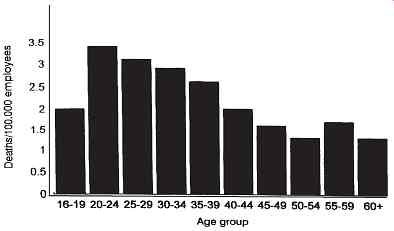

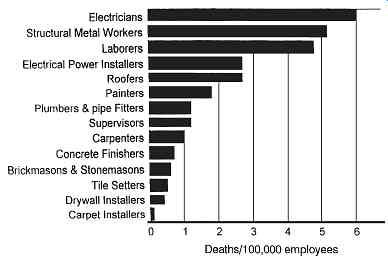

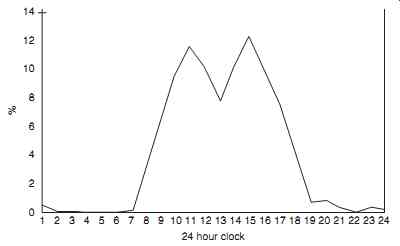

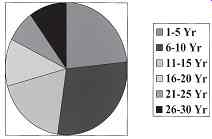

The researchers studied 1980-1991 data, showing the age distribution of those construction workers killed in electrical fatalities ( FIG. 2), their job titles ( FIG. 3), and the time of day when fatalities occurred ( FIG. 4). The data showed that a worker is vulnerable to an electrical failure at any age, regardless of job title. The pattern of fatality time of day reflects the increasing activity typically seen on a construction site from start of day to end of day; an interpretation of this FIG. is that the more workers on a job site, the more likely it is that a fatal incident will occur.

FIG. 2 Distribution of electrical fatalities among U.S. construction

workers, 1980-1991. Adapted from FIG. 2 from Ore and Casini's 1996 report,

this illustration shows the number of deaths per 100,000 workers by age groups.

FIG. 3 Job titles of electrical fatalities among U.S. construction

workers, 1980-1991.

Considering construction fatalities from the perspective of crane hazards, when Suruda and colleagues studied U.S. construction crane fatalities for 1984 to 1994, 196 of 502 fatalities, or 39 percent, involved electrocution. The historic new OSHA standard addressing the use of cranes and derricks in construction published by the Federal Register on August 9, 2010, in part addresses fatality risks associated with crane and derrick operation near power lines.

FIG. 4 Time of day of electrical fatalities among U.S. construction

workers, 1980-1991. This graph shows the percentage of U.S. construction

electrical fatalities compared across a 24-hour period.

Often the question is asked, "Do electrical fatalities or injuries mostly occur in people new to their jobs?" This is a question that tries to sort out differences in the fatality trends in relationship to the worker's job experience, rather than the worker's age while on the job.

Data from the International Brotherhood of electrical Workers (IBeW) addresses this question in part. Power line transmission and distribution worker fatalities for 1975 to 1988 were previously reported by seniority on the job ( FIG. 5). Note higher seniority status does not confer protection from an electrical fatality in the workplace or from nonoccupational electrical trauma, as discussed in the following section.

FIG. 5 power line transmission and distribution worker fatality experience

by seniority, 1975-1988. This shows the distribution of power line

fatalities in IBeW linemen from 1975 to 1988 by years of seniority. (IBEW

Transmission and Distribution Worker Data.)

==========

Table 2 Nonoccupational electrical Trauma Scenarios

Setting Source Fatality/injury description

Homes receptacles 3900 injuries annually, with 33% young children inserting metal objects*

Clinical/hospital Iatrogenic pectoral muscle damage after defibrillation† police action Stun guns Associated with more than 50 fatalities since 2000†† educational/recreational Swim pools electrocutions and electric shocks§

Vending electrocutions, shocks¶

==========

Nonoccupational electrical trauma

Compared to workplace electrical trauma, nonoccupational electrical injury and fatality statistics are not collected routinely, limiting injury and fatality estimates. Typically, nonoccupational electrical injuries are sustained in personal or public settings, such as households, medical facilities, emergency response sites, and educational and recreational locations ( Table 2).

A Consumer product Safety Commission 2010 report considered product-related electrocutions between 2002 and 2007 using electrocution death certificate records from the National Center for Health Statistics and the Consumer product Safety Commission data bases. Product-related incidents were included in the analysis if the products involved fell under the jurisdiction of the Consumer product Safety Commission. Work-related incidents were excluded. During the study period, there were 2350 electrocutions, with males affected six times more frequently than females. Twice as many people ages 40 through 59 years were electrocuted as those 19 years and younger. Following are the three most common product categories associated with electrocutions between 2005 and 20078:

• Small appliance

• Power tool

• Lighting equipment

Fatality- and injury-related costs

According to survey research from the Integrated Benefits Institute including a traditional view of paid benefits, workers' compensation costs in 2002 for work-related injuries and illnesses were estimated at 9 percent of health costs.

More than 1.85 million U.S. employees work in the construction trades, as shown by 2010 U.S. Census data (Table 3) ; the annual value of U.S. construction put in place by type of construction ( Table 4) is also shown for 2002.

A utility industry study reported that for a series of reviewed cases occurring between 1995 and 2004, while 3.7 percent of the cases involved thermal burn or electric shock injuries, the costs were nearly 13 percent of medical claims expenses.

A single injury can cost an electrical utility a million dollars.

========

Table 3 Construction employment, 2010-10

Occupation employment, 2010 Carpenters 509,700 Construction laborers 608,810 Construction managers 153,100 electricians 384,100 Operating engineers and other construction 203,020

Equipment operators

Table 4 Value of U.S. Construction put in place, 2002

Type of construction ($ millions) Office 37,578 Hotels 10,285 religious 8217 Other Commercial 55,879 educational 68,995 Hospital and Institutional 22,366 public Housing & redevelopment 5507 Industrial 18,486 electric Light and power 24,789 public Utilities 54,370 Military 18,284 All Other Nonresidential 49,362 TOTAL 374,118

========

ELECTRICAL EVENTS

The size of an electrical event may range from an almost unnoticeable release of energy, like localized heating in a conductor or a very brief light flash in a low-voltage installation, to a massive explosion from an escalating arcing fault in a multiphase high-voltage system.

The scale and time factors lead to differences in the amount of energy in an electrical event, and by extension, differences in the destructive effects.

Consider when the electrical energy release in an event is relatively small and slow, as for example, with ohmic heating in a fluorescent fixture ballast. This heating effect may be noticeable only during a preventive maintenance check of the fixture's performance.

However, the electrical hazard can lead to a potentially fatal consequence if it serves as an ignition source in the presence of combustible dust, vapor, or other ignitable materials.

Fires and explosions from combustion of these hazardous materials can follow, placing workers and other occupants and neighbors of the facility at risk. Another aspect of the hazard relates to the response to it: If an employee brings a metal ladder under the light to repair the fixture while electrical current is flowing, the employee may be startled by a shock, causing a loss of balance on the ladder. Or worse, the employee may be electrocuted and die. For this reason, use of nonconductive equipment and tools and local disconnects at luminaries is potentially lifesaving.

In another scenario, an employee may come in unprotected contact with an electrical shock hazard. Then electrical energy can flow from the hazard to the employee, essentially as if the employee has become part of the source circuit. The employee's connection to the circuit can be "in series," as when current flows "into" or "through" the body, or the connection to the circuit can be "in parallel," as when current flows over the employee without creating a potential electrical gradient across specific tissues in the body. Complex connection in both series and parallel paths may occur as well.

In a third scenario, an employee or equipment the employee is using can enter an air gap between conductors. This may happen initially intentionally as, for example, in the high voltage scenario of live-line work. Another possibility is that the employee or the employee's equipment may enter the air gap between conductors initially accidentally, as with the operation of equipment too near to a power line. As a result of entry into an air gap between conductors, a conductive channel can open between the source and the employee or the employee's tool, resulting in an electrical arc fault. With an electrical arc fault, a large amount of electrical energy can flow in an ultrashort time, creating an event that transforms electrical energy into multiple forms of energy flowing from the source into the electrical event space.

As suggested in the section on the hazards of electricity, an electrical event can be formally described using

• equipment voltage and involved current.

• occurrence of an outage resulting in disruption of service, manufacturing, or industrial process.

• destructive effects of the energy released in the incident.

As earlier discussions about the National electrical Code have indicated, hazard rating of electrical installations is variable, depending on the location of the installation as well as the surrounding operations and conditions. While consensus exists on how to rate electrical installations, there is no widely agreed-on scheme to rate an event's electrical failure severity.

As a general guide, the National Fire protection Association's (NFPA) Failure Mode and effects Analysis (FMeA) can be used as a qualitative rating from 0 to 4, with a 0 rating indicating an event for which the hazards result in no effect; a rating of 1 suggests a slight effect; a rating of 2 is for a moderate effect; a rating of 3 is for an extreme effect; and a rating of 4 suggests a severe effect.

If an electrical event produces a fire, the severity of the fire's results may be rated. For example, Table 5 summarizes Noon's suggestions for fire scene ratings that can be assigned during an investigation based on inferences using the materials present.

Electrocution and electrical fatalities

The term electrocution refers to an electrical event with electrical current exposure resulting in death. The implication is that the current flow has caused an electrical shock with subsequent physiologic effects interfering with life. While an informed speaker may use the term precisely, sometimes survivors or their caregivers use the term electrocution to refer to a "near death" electrical exposure rather than a more commonly experienced "shock" that might be experienced as "routine" or "innocent."

==========

Table 5 Severity of Fire Investigation Scenes

Rating -- Description

10 Materials are gone, wholly burned away

9 Materials are mostly gone, some residual

8 Materials are partially gone, recognizable residual

7 Materials are burned all over but shape intact

6 Materials are mostly burned

5 Materials are partially burned

4 Materials are slightly burned

3 Materials are heat damaged from nearby fire

2 Materials are heavily smoke damaged

1 Materials are slightly smoke damaged

0 Materials exhibit no significant fire damage

==========

Electrical accident fatality is a general-use phrase seen in news reports meaning either electrocution, or death resulting at the time of the electrical accident. This phrase may include fatalities, associated shock, or other forms of energy released at the time of the electrical accident, in particular those causing physical changes including burns, blast effects, or radiation damage.

Electrical injury mortality is a medical statistics phrase that suggests that a person who was injured in an electrical accident lived long enough to receive medical care for injuries but the medical care was not followed by survival.

It's important to appreciate that an electrical event can produce a fatality or injury even when there is no electrical current flow or electrical shock to the victim. This might be the situation, for example, when a victim is caught in an electrical ignition fire, explosion, or blast. In this case, the "root cause" of the accident is electrical, but the mechanism of death or injury is from thermal, acoustic, radiation, or blast exposure related to electrothermal chemical (ETC) combustion.

Employees can also be killed or injured after an electrical event if they are surprised by an energized source, either through a spark, like a static "zap" to exposed skin, or through a noise, like a sharp "gunshot"-type sound close to the head. The surprise can lead to an unintended body movement that might be characterized as a "startle response." If the startle occurs at the top of a ladder or scaffold, the direct mechanism of death or injury can be through a fall. If the startle occurs in proximity to other energized equipment that is moving, death or injury can result from a body part being caught in or by the moving equipment. If the startle results in a tool or small metal piece such as a screw falling into operating equipment, the metal object can serve to initiate a fault condition that disrupts the equipment's performance, possibly leading to a cascade of events that is more damaging than the spark or static discharge that startled the employee in the first moment of the incident.

Fatal and nonfatal electrical incidents share three characteristics:

1. Unintentional exposure of employees to electrical energy

2. Compliance failure in at least one aspect of electrical design, installation, policies, procedures, practices, or personal protection

3. Energy transfer to exposed employees in some combination of electrical, thermal, radiation, acoustic (pressure), mechanical, light, kinetic, or potential energy

What is the difference between fatal and nonfatal electrical incidents? The answer depends in part on whether the question is asked hypothetically, as in a "what if" planning scenario, or whether the question is asked retrospectively after a traumatic accident has occurred.

Hypothetically, based on human physical and biological characteristics, we know that a fatal electrical event transfers a greater amount of energy to its victim than a nonfatal situation. This knowledge about the fatal risk of energy transfer underlies the use of equipment design (for example, required doors, specified space clearances, venting systems on equipment to discharge combustion products, "umbilical corded" controls, infrared monitoring ports for "doors closed" heat monitoring), and barrier protection (such as ppe, including leather gloves, flash suits, safety glasses, face shields, long sticks, extended handles, and flame-resistant clothing) discussed in this handbook.

By reducing the amount of possible energy transfer during an unintentional electrical exposure, strategies including equipment design and barrier protection can increase the likelihood of survival after an electrical incident.

Retrospectively, if two people experience the same electrical incident and one dies while the other survives, the difference in survival may come down to nuances in the victims' innate individual differences and their spatial and temporal relationship to the electrical hazard at the time of the energy release, transformation, and transfer. Medical and legal privacy protections tend to reduce accessibility to accident details, so systematic information is lacking about how various scenarios unfold.

Generally, different forms of energy vary in their lethal exposure "doses." When multiple forms of energy are involved in an electrical event, multiple lethal or sublethal doses of energy may flow from the event, transformed from the electrical hazard source and transferred to nearby employees, and may result in highly variable damage to the body.

Medical aspects

While the structural or environmental consequences of an electrical event may be rated through schemes like FMeA, the medical consequences of an electrical incident cannot be readily predicted from a rating or event description. This is a frustrating aspect to under standing how survivors look or feel after an electrical exposure.

Three questions are central to understanding the fatalities or injuries seen as health effects following an electrical failure:

1. How much energy was released during the electrical event?

2. What forms of energy were released during the electrical event?

3. What parts of the released energy transferred to the affected worker?

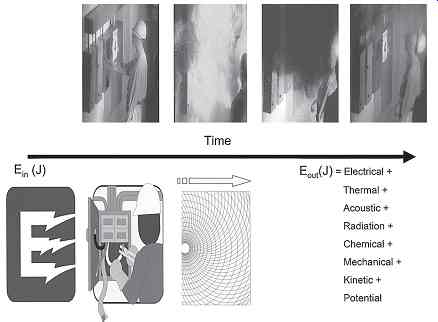

A schematic of an electrical incident with photographs of an experimental simulation of a "real-world" scenario is shown in FIG. 6.

As the illustration suggests, an electrical incident unfolds over time. Again, when an electrical fault occurs, electrical energy is transformed and transferred, leading to multiple possible exposures. Tissue damage is related to the amount of energy that builds up or is absorbed into the tissue as a result of the exposure.

Voltage ratings, available fault current estimates, and incident energy calculations permit a guess at the amount of electrical energy that may be involved in an electrical incident.

Practically, when more than one person is present at an electrical incident, more than one health effect from the incident is possible, ranging from no effect to fatality. Such varying effects result from individual differences in size, shape, position, and body composition.

Although it may seem unreasonable to employers and coworkers, the same exposure can and often does produce different levels of injury in individuals involved in the same event.

People can vary in their susceptibility to any single exposure (i.e., electricity, heat, radiation, noise, and pressure) because of their individual differences. Moreover, an exposure itself can vary, depending first on the event timing and, second, on the positions in space where the hazard is released relative to the affected employees. Since two or more people cannot occupy the same point and time in space, even during the same accident their positions cannot be exactly the same.

Much scientific knowledge exists about how the body responds to direct electromechanical contact with 50- to 60-Hz electricity generated for electrical power, as discussed in Section 1. For fatality and injury scenarios in which electrical shock is the dominant expo sure, the tissues' vulnerability to electrical forces is key because biologic tissues vary in their electrical conductivity. This variation explains uneven patterns of damage on a limb, where bone, muscle, tendon, blood vessels, and nerves may demonstrate differing degrees of loss.

FIG. 6 Schematic of electrical event energy transformation and transfer

with photographs of experimental simulation of a "real world" scenario.

Industrial scenario with electrical energy input to a wall panel box

while worker is standing nearby. At the moment of the electrical incident

event, electrical energy transformation occurs. Uncontrolled energy release

follows, resulting in the transfer of electrical and other energy forms

to the space and nearby worker. Simulation photographs parallel schematic

illustration. A staged test with a mannequin industrial worker standing

nearby a panel box is shown under high voltage laboratory conditions

with 480 V and approximately 22,000 A available. An electrical failure

is staged to show a typical workplace scenario.

Nonelectrical effects in electrical events

As power density increases across more compact spaces, more fault energy is available in electrical installations. With installations designed to be compact, there are smaller spatial cushions and consequently less physical or spatial barrier protection emerging in innovative designs. As a result, there may be less time and less physical distance through which an unintentional release of energy can be dissipated during an electrical event. With higher power density and smaller, more compact spaces, the risk of collateral damage from the nonelectrical forms of energy increases.

High power density in a confined space can have bomb-like potential. As a consequence, an electrical event can behave like a closed blast explosion. For example, the potential ignition of 1 MW is roughly equivalent to the potential ignition of one stick of dynamite.

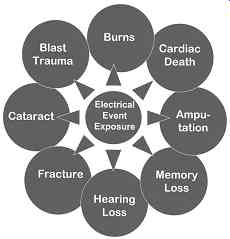

One stick of dynamite is roughly 1/3 lb of TNT equivalent. So a 100-MW scenario can be represented as loaded with 100 sticks of dynamite. Or a 300-MW scenario can be represented as loaded with 100 lb of TNT. A closed space with an electrical event creates the possibility of closed blast health effects. At a pole top in a vacant field, the space is more like an open area suggesting an electrical scenario at pole top is more likely to cause injuries similar to those seen with a free blast. Blast trauma may include destruction from shrapnel, confined space air contamination, acoustic or pressure effects, and acceleration-deceleration brain effects. In sum, when an electrical event involves more than a direct electromechanical current exposure, the traumatic consequences can vary, as the bubble diagram suggests ( FIG. 7).

FIG. 7 illustrates the possible traumatic outcomes.

Apart from the electrical sources of thermal energy (ohmic or joule heating, radiation with arcing), fire and molten metals at the scene can lead to heat transfer from the combustion of nearby installation, building, and equipment materials. Inhalational injury associated with fire can complicate the survivor's chances for recovery, especially in an event that has also included a blast.

FIG. 7 possible trauma following an electrical event. This bubble diagram illustrates the kinds of medical problems that may follow the exposure to an electrical event. The body's response to the transferred energy from the event in part depends on the form of energy, the dose, and the duration of the exposure.

==========

Table 6 Timing of Incident response and Survivor experiences after electrical events

Experience ----- Timing

[ Incident Response

Event:

Investigation:

Litigation: Survivor

Worker reflexes

Triage and medical evacuation

Stabilization and initial evaluation

Medical and surgical intervention

Hospitalization

Discharge to outpatient services

rehabilitation

return to work planning

reentry to employment

plateau in recovery

]

[ Fractions of milliseconds Weeks to months Years Seconds event to hour 1 Hour 1 to hour 8 Hour 8 to hour 24 Day 2 to day 9 Day 10 to day 30 Day 31 to day 89 Day 90 to day 119 Month 4 to month 60 Beyond 5 years

]

==========

| Top of Page | PREV. | NEXT | Index |