AMAZON multi-meters discounts AMAZON oscilloscope discounts

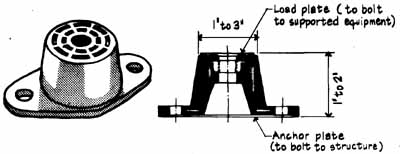

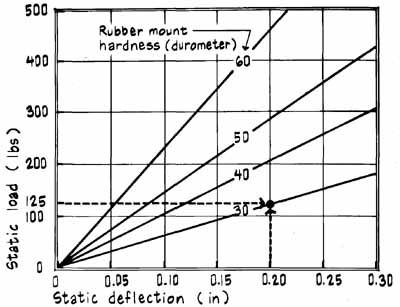

The graph below shows the static deflection under load for examples of rubber or neoprene-in-shear mounts of various hardnesses as measured in durometer. Neoprene-in-shear mounts usually are shaped like truncated cones (similar to upside-down flower pots) and are bonded to top and bottom metal plates. Loads from any direction cause a shearing reaction which absorbs vibrations.

Shear occurs when the particles of a material slide relative to each other rather than push together as occurs with compression. Ribbed (or waffled) neoprene pads also provide some shearing action and absorb energy by expanding laterally into the spaces between the ribs. Pads can be stacked to obtain larger deflections, in which case stainless steel separator plates should be used between layers to help evenly distribute the load.

Durometer, a measure of hardness, is expressed by a scale of 0 (soft) to 100 (hard) from surface indentation measurements. Rubber mounts (usually 30 to 70 durometer) are often used to vibration-isolate mechanical equipment that's relatively small or operated at high speeds. For example, a small engine weighing 500 lb and having a driving frequency of 2000 rpm requires a static deflection of about 0.20 in for “most applications” when mounted on grade (see design graph on preceding page). If the engine is to be supported by four mounts (one at each corner), a mount with a static deflection of 0.20 in for a load of 500/4 = 125 lb will be required. Therefore, use a rubber mount which has a durometer of 30 (see intersection of dashed lines on graph below).

Install mounts so the load will be evenly distributed to the mounts, and avoid installing load bolts which are tightened to the foundation—these rigid connections eliminate the isolation effectiveness of the mounts.

Reference:

L. H. Bell, Industrial Noise Control, Marcel Dekker, New York, 1982, p. 359.

Next: Vibration Isolation Guidelines