AMAZON multi-meters discounts AMAZON oscilloscope discounts

It is essential that we examine what an NC machine is, learn how it is operated, and how it fits into the general picture of robotic machines. It is a machine which is controlled "by the numbers". What that means is that it is a lathe, a milling machine, a drilling machine, or something of the sort, that is programmed to move the cutting tool, drill, or whatever, exact distances to within .0001 inch to perform whatever task has been programmed for it, using a perforated tape containing the movement commands and instructions. A computer, naturally, is located in the system, and it receives the instruction numbers from the tape and knows what they mean.

For example, if a drilling tool is to move one inch on the X axis, over some plate which is to be drilled, and move two inches up the positive Y axis to exactly locate the center of the hole to be drilled, then the tape instructions would consist of two numbers. If the drill is to go down one inch to pierce through the metal plate at the specified position, then a third number is added to the instruction sequence. Since these instruction numbers are always in the same sequence, that is, the X axis instruction, the Y axis instruction and the Z axis instruction, then all that is needed is some way to space these commands on the perforated tape, which is read by an optical reader. This gives the commands to the computer which, in turn, controls the stepping motors, or the closed loop servo-mechanism, to make the machine elements do what the instructions say it should do.

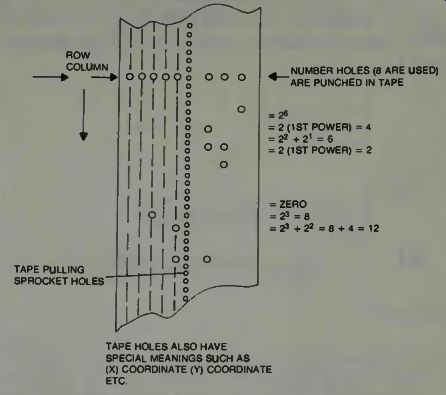

The way the commands are spaced is by using a tab key on the tape perforating keyboard. This, like a typewriter tab key will cause the instructions to line up properly by forming a special kind of "end of command block" code which lets the computer know that another set of movements will be the next block's numerical grouping. After the machine drills the hole, as previously specified, it moves to a home or starting location where the coordinates are (0), (0), (0). The next command, which might consist of the numbers (5000), (6000), and (1000), tells it what to do next. See if you can interpret what the above figures mean using the information we have already given you. The tape used to store and present the command-instructions to the computer may look like that shown in Fig. 1. The numbers are in Binary form, i.e., the rightmost column is the 20, the next, 21, the next 22 and so on.

Thus the position of the holes in the tape specifies a given number, and that number is a command for the machine tool movement. The rows of holes come in a specific sequence, as previously stated, which tells the machine's computer control brain how to move the tool, first in the X coordinate, then in the Y coordinate and in the Z direction.

This, as you can realize, gives the position of a point in three dimensional space.

Fig. 1. A sketch representation of an NC machine's control tape. The tape

is punched with holes which are converted into a binary number across the rows.

Many rows of holes produce many numbers which designate the machine's operation. The column in which the punched hole appears governs its numerical or "special" operational meaning.

CHANGING TOOLS AND RANGE OF OPERATIONS

The NC machine can do marvelous things. If a source of tools is supplied to it, on a circular retaining unit, for example, it can, when so instructed, change its operating tool for each required operation. What it does is to move toward the circular retainer, which, itself has rotated under computerized command to a given position, attach its working head to the tool in a specific position, then the head is moved back to the work and to the position where that tool is to be used. When the task for tool number one is finished, the head will return the tool to the circular retainer, which grips it, the retainer rotates again bringing a new tool into the acquisition position, and the head latches onto this new tool, and repeats the working procedure. A very wide range of operations from milling, to drilling, to smoothing, to contour shaping, can thus result.

FUTURE OF NC MACHINES AND ROBOTICS

Some of the scientists who develop and design these machines believe that in the future there will be a marriage of the NC machine and the robotic machine. The NC machine will be tended by an industrial robot at each advanced work station. All control data will be verified by computerized graphics. Sony has a color TV plant in Taiwan that produces a package product, ready to ship, with less than $1.50 invested in labor. Much of the work is done by work stations like this. A reference on NC machines which might be of interest to you is NUMERICAL CONTROL PART PROGRAM MING written by James J. Childs and published by Industrial Press Inc.