Gary Morton of Hi-Tek examines the selection of integrated circuit pressure transducers as acoustic sensors in microphones and other pick-ups and explains their use in acoustics.

Fig. 1. This early monolithic piezoresistive

transducer is available in three forms-gauge, differential and absolute--and

includes thick-film thermistor temperature compensation external to the

sensor element.

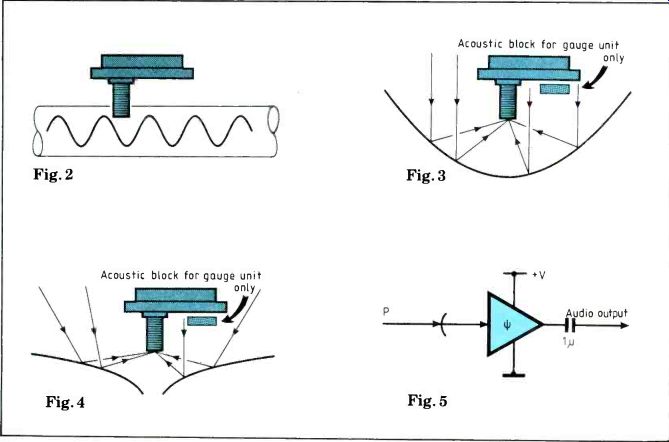

Figs. 2-5. Transducer can be used as it is for musical instruments or close

microphones, Fig. 2, but for stand-off mics the port should be shortened to

accept the wider angles, Figs 3, 4. Transducer requires only excitation voltage

and coupling capacitor to function as a microphone, Fig. 5.

Integrated-circuit pressure transducers are ideal as an acoustic sensor in microphones, hydrophones, sound level meters, musical instrument pickups, audiometers, and other sound detection applications. The i.c. transducer, of which a typical example is shown in Fig. 1, has a wide amplitude response (from zero frequency to 50kHz) and a built-in operational amplifier that provides a high-level signal output for audio range (up to 30kHz) pressure variations.

Because the transducer diaphragm's natural resonance is outside the audio range (-50kHz), it does not generate audio-range harmonics from input sound waves, which totally eliminates tricky microphone squealing even in heavy feedback situations. The i.c. pressure transducer's high accuracy, which can be further improved by auto-referencing, qualifies it for use in precision audio instruments.

With the pressure port tube in place, the i.c. transducer has a directional acoustic pickup pattern that can be broadened by reducing the length of the tube. If the tube is removed, the pickup pattern is similar to a high quality cardioid microphone. The transducer can be used for musical instrument pickups (Fig. 2) or for close-up directional microphones, but may require tube modification for other types of microphones.

It is important to note that the port must be protected by an acoustically compliant material to prevent breath moisture from reaching the transducer circuit in any microphone, wind instrument, or other application where someone could blow into the port.

For stand-off microphones, the additional gain can be obtained by use of reflective sound collectors. A paraboloid reflector for directional pickup can be used, as shown in Fig. 3, or a hyperboloid for wide angle pickup, as shown in Fig. 4. In either case, the pressure port needs to be shortened to accept the wide angles within the acoustic system.

Acoustic transducer selection

For acoustic measurements, the most sensitive gauge pressure transducer is normally selected. The sound pressure waves are usually small, requiring high sensitivity, and the gauge inlet balances out atmospheric pressure. Since sound pressure waves go both positive and negative around the mean atmospheric pressure, a pressure transducer with a ±5 psig is ideal for the following applications. Devices which have a response centered at 15 p.s.i. (atmospheric pressure) can also be used and often have the advantage of not requiring an acoustic block for the gauge inlet.

For microphones and other audio pickups, the transducer only requires excitation voltage VE and a 1 µF series capacitor to function effectively as a sound sensor, Fig. 5. The sound can be coupled in by any appropriate means as discussed above and by following the general principles used for all acoustic pickups.

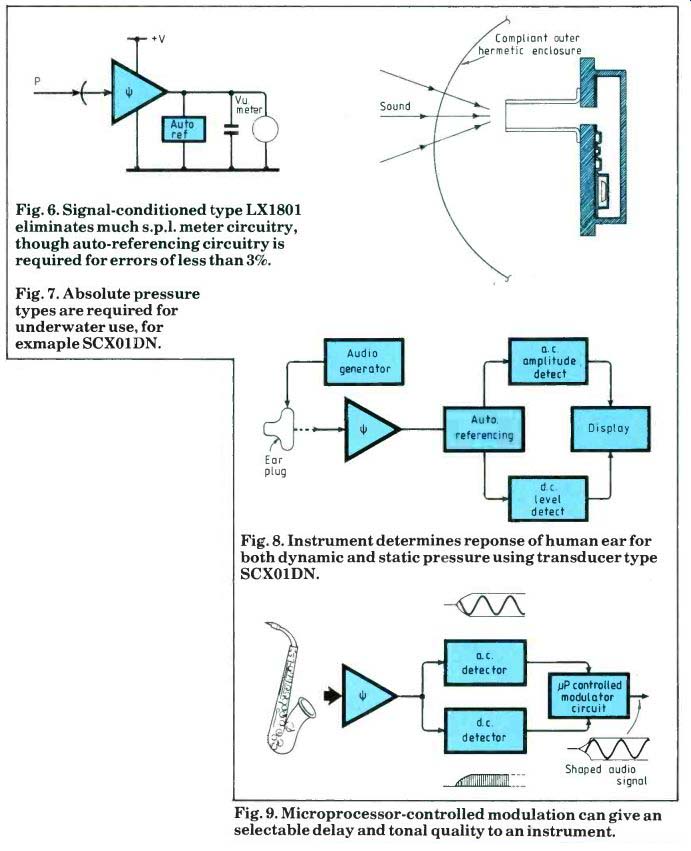

Conventional sound pressure level meters normally use a microphone pickup. The resulting signal is amplified, re-titled and used to drive a meter readout. Since the i.c. transducer's signal is already amplified, it eliminates much of the s.p.l. meter circuitry, Fig. 6.

But to be accurate, the s.p.l. meter must be precisely coupled with the sound pressure level input. If an accuracy better than 3% of amplitude is required, either restricted temperature range or normal mode auto-referencing should be used.

In underwater sound pickup applications, an absolute pressure transducer is used. In this case, a very simple, hermetic enclosure needs to be used to protect the sensor. Fig. 7 shows an example.

The audiometer and tympanometer combines the capabilities of the i.c. pressure transducer for precise sensing of both audio pressure variations and static pressure. As shown in Fig. 8, this instrument uses an audio generator to teat the response of the human ear. The audiometer function relies on patient response and hence is only required to measure the a.c. amplitude (and frequency, if desired) of the audio signal entering the ear via the ear plug. The tympanometer measures the compliance of the ear drum without patient cooperation by comparing a.c. amplitude with d.c. level shift resulting from back pressure between the ear plug and the ear drum. Both normal mode and common-mode auto-referencing can be used to increase measurement accuracy.

Like the audiometer and tympanometer, the sphygmomanometer makes use of both a.c. and d.c. pressure detection level measurements. It measures the absolute blood pressure levels for the systolic and diastolic points while monitoring the phase of the heartbeat cycle for more accurate location of the "true" systolic point, the point where the apparent heartbeat at the point of measurement undergoes a change in phase.

In brass instruments, the musician's mouth and throat are part of the instrument's air column. As such, the input air pressure is an important determinant of pitch, volume and the tonal quality of the sound.

But in the woodwinds, the musician's mouth and throat are not part of the air column; they are part of the reed. And as such the input air pressure is associated with pitch only, and not basically with the final quality of the sound. Thus the need of woodwind players for an external method to manipulate the tonal quality of their instruments.

Fig. 9 shows a fundamentally sound system for woodwind instruments-the musician's concept of the perfect microphone. It consists of an i.c. pressure transducer coupled tightly to the instrument's mouthpiece, serving both as a microphone and as a sound pressure meter. If the a.c. signal is modulated by the d.c. signal, the output of the sound system is quite similar to that of an instrument with square-law attack. The woodwind has now already acquired the attack quality of a brass; it's still up to the musician as to how the attack is to be used.

Such a system using microprocessor-controlled modulation gives an instrument of selectable bell size, a tonal quality that varies from "fat" (full and rich) to "crisp" (sharp and clear-edged), and something that no echo chamber could even achieve-selectable delay. A clarinet, for example, can be given the attack of a trombone with the bell of a sousaphone, and yet retain the clarinet's characteristic playing facility

Fig. 6. Signal-conditioned type LX1801 eliminates much s.p.l. meter

circuitry, though auto-referencing circuitry is required for errors of

less than 3%.

Fig. 7. Absolute pressure types are required for underwater use, for example SCX01DN.

Fig. 8. Instrument determines response of human ear for both dynamic and static pressure using transducer type SCX01DN.

Fig. 9. Microprocessor-controlled modulation can give an selectable delay and tonal quality to an instrument.

----------------------

Also see:

Mains communication without tears

==========

(adapted from: Wireless World , Dec. 1986)