Authors: B. V. PISHA and GEORGE ALEXANDROVICH

On the evening of November 2, 1920, radio station KDKA in East Pittsburgh,

Pa. broadcast to a tiny but eager national audience the results of the Harding/Cox

presidential election. That is the date given in history books as the official

birthday of commercial radio broadcasting. As other stations followed suit

with nation al hookups, the word was that the phonograph record, a mere 43-year-old,

had not long to live. Why listen to "canned" music on phonograph

re cords when you could hear live orchestras playing from hotel ballrooms,

symphony orchestras performing in concert halls, and operatic personalities

singing from famous opera venues? Despite these divinations, the phonograph

record endured, and in fact it became even more popular as a direct consequence

of radio broad casting.

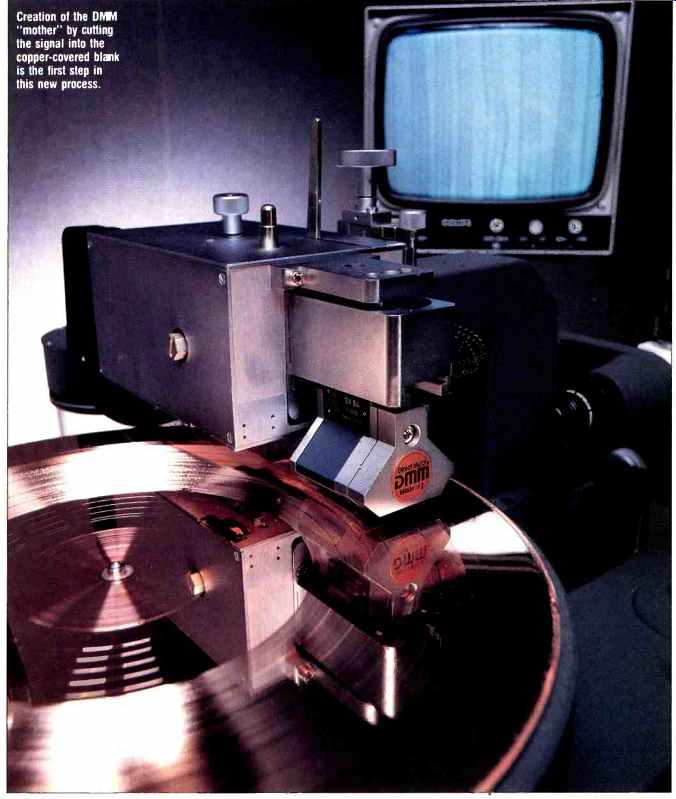

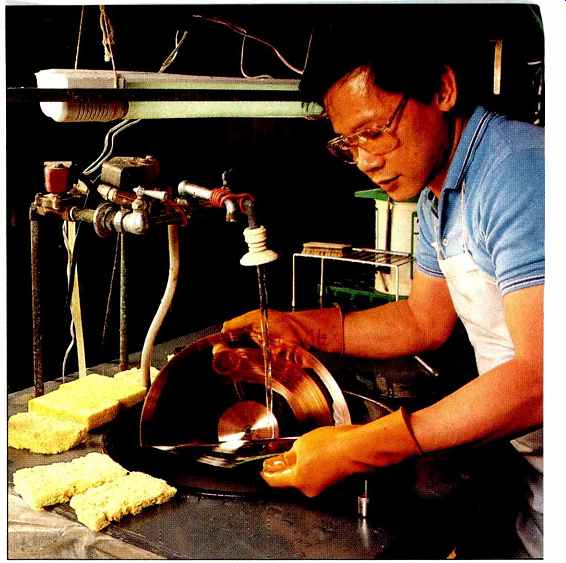

-----Creation of the DMM "mother" by cutting the signal into the

copper-covered blank is the first step in this new process.

Introduction of the monophonic reel to-reel tape recorder in the American marketplace back in the late 1940s, and its growing popularity in the '50s as a stereo sound format, sparked an other flurry of predictions that the phonograph record was doomed. But those predictions turned out to be similarly incorrect.

Enter North American Philips to spread the gospel of the audio cassette, at first in a mono format which evolved into stereo. Following improvements in blank-tape technology and the advent of Ray Dolby's consumer noise-reduction system, the cassette moved up the scale to establish itself as a true high-fidelity medium. Recently, just a couple of years ago, sales of prerecorded cassettes topped those of LP records. Rumors again flowed rampant and the doomsayers had an other field day, proclaiming that the phonograph record was heading for the graveyard. Not so! Comes the digital Compact Disc with all its technological bravura, and the rumors are again flying that the phonograph record is about to die.

(We amend that; people are saying the analog phonograph record is about to die.) But as Bing Crosby crooned it in his days with Paul Whiteman (on Columbia picture record 1444-D), " 'Tain't So, Honey, 'Tain't So."

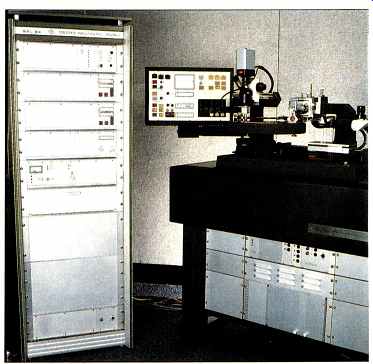

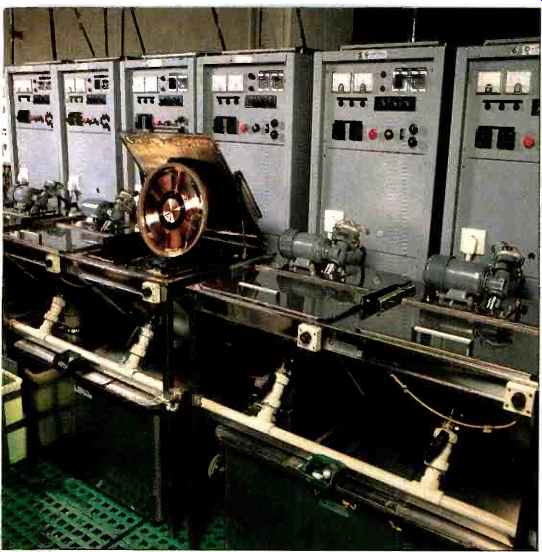

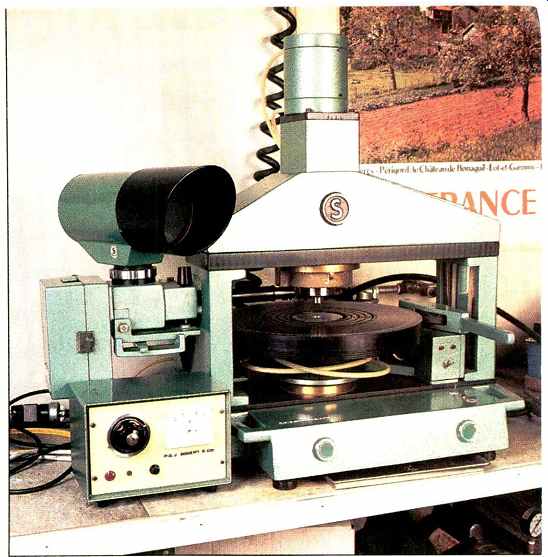

----The equipment used in the DMM system includes a Neumann VMS 82 lathe

with an SX 82 cutterhead, TV groove monitor, SAL 84 cutting amps, and a computer

to control the variable pitch and depth.

During this half-century plus, the makers of phonograph records were not sleeping. They moved from the Acoustical Era, with its 78-rpm shellacs (actual speeds ranged from 67.92 to 87.80 rpm), to the Electrical Era, then into the Vinyl Mono LP Era, then the Stereo LP Era. Then came the Direct-to-Disc Era (a new version of the old direct-to-disc recording approach that was used in the days of 78s) and finally the Digital/Analog Era.

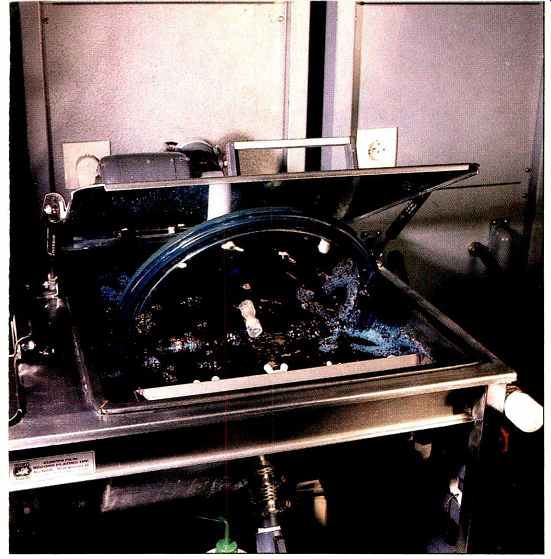

-----Europadisk does both cutting of masters and plating in near clean-room

conditions, which keeps possible contamination of the record groove down

to the minimum.

Concurrently, during that half-century, audio equipment manufacturers were also not sleeping. R&D labs kept busy, designing better record-playing equipment-namely automatic changers, then better turntables and tonearms, and along the way, better cartridges. Manufacturers stopped producing steel and cactus phonograph "needles," replacing them with sapphire-tipped styli. These evolved into models with multi-faceted diamond tips, some costing hundreds of dollars.

And now, we predict-with perhaps a trace of trepidation in our temerity that the analog record will survive! Away with ye, doomsayers! What is the basis for such defiance of the establishment? A simple acronym-DMM.

DMM stands for Direct Metal Mastering (or Direct Metal Master), a technology introduced in 1981 that effectively moves the analog phonograph record into a new era. First came tinfoil (circa 1877) as the mastering material, then beeswax shortly thereafter, then shellac somewhat later, then finally lacquer (acetate). DMM technology moves the phonograph record into the Copper Master Era.

That in itself might not seem like an important change, but its significance lies in what copper mastering means to the listener/consumer. According to Europadisk, Ltd., the first DMM licensee in the United States, DMM leads to finished phonograph records which have:

Up to 15% more playing time (as much as 40 minutes total per side);

Substantially reduced noise and distortion (10 dB less over the entire frequency range). The signal-to-noise ratio is typically 75 dB;

Noticeably improved high-frequency and transient response;

Improved groove depth and spacing between grooves, to prevent stylus "skipping";

A marked increase in stereo separation, particularly in the low frequencies (e.g., greater than 20 dB at 100 Hz and below); and

Cleaner, tighter bass response.

Additionally, it provides these benefits at no increase in price. (The retail cost differential between analog and CD continues to be in favor of analog, even when DMM is used.) To the recording fraternity, says Europadisk, DMM means:

Elimination of lacquer-related problems such as swishes, echo, tickiness, and other sound blemishes;

No cutting "horns";

No lacquer-plating or lacquer-aging problems;

Virtual elimination of the need for re-cuts; and

Faster stamper production (as a consequence of bypassing two plating steps).

In effect, DMM is analog gone state of-the-art, or the highest form of analog phono record. While DMM technology is not perfect-and neither is CD technology at its highest point yet-DMM records can be said to be at the same level as CDs in terms of their ascendancy toward the goal of perfect sound reproduction.

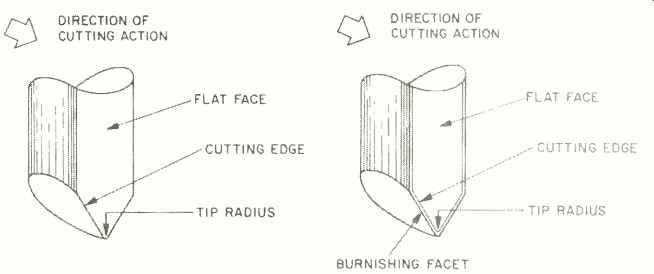

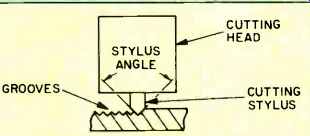

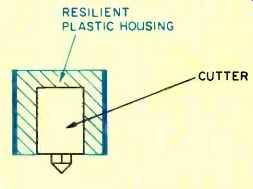

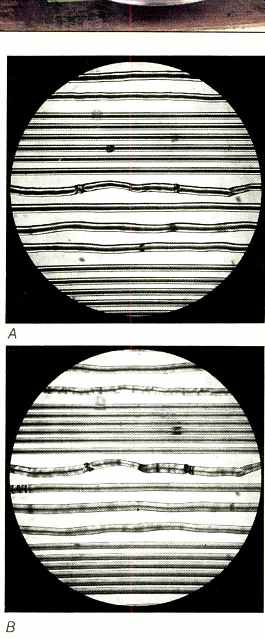

(left) Fig. 1-Cutting stylus for Direct Metal; (right) Fig. 2-Cutting stylus

for conventional Mastering. lacquer mastering.

------------------

Table 1--Performance data for playback of DMM masters, measured by Teldec, using a Shure V15 Type V pickup.

Frequency Response: 20 Hz to 20 kHz, ± 1 dB, over entire cutting radius from outer rim to innermost allowable modulation diameter. No losses up to wavelengths of 10 µm.

FIM (DIN 45511): Less than 0.3% (315 Hz/3.15 kHz, 4:1) for 5 cm/S peak recorded velocity, re: RIAA equalization for 1 kHz. (Note: Distortion is for single-channel recordings at 11-inch/280-mm recording diameter; distortion wilt be higher for playback at smaller diameters.)

THD (DIN 45503): Less than 0.5% for 5 cm/S peak recorded velocity at 1 kHz. (See note above.)

Twin-Tone IM (DIN 45503, IEC 268): Less than 0.1% for 1.000 and 1200 Hz at 5 cm/S peak recorded velocity. (See note above )

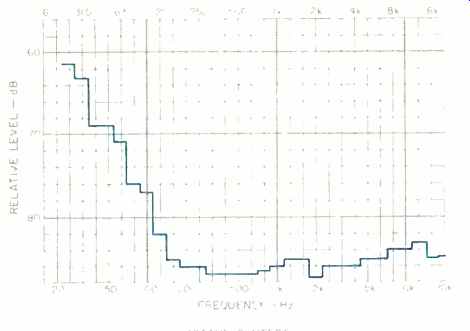

S/N: Greater than 70 dB (typically 75 dB), A-weighted (per DIN 45633, IEC 179). re 10 cm/S peak recorded velocity. See Figs. 3A and 38 for spectral distribution.

Groove Echo Attenuation: Greater than 65 dB for 10µm land between grooves and greater than 75 dB for 150 µm land, re: 8 cm/S peak recorded velocity at 1 kHz, single channel.

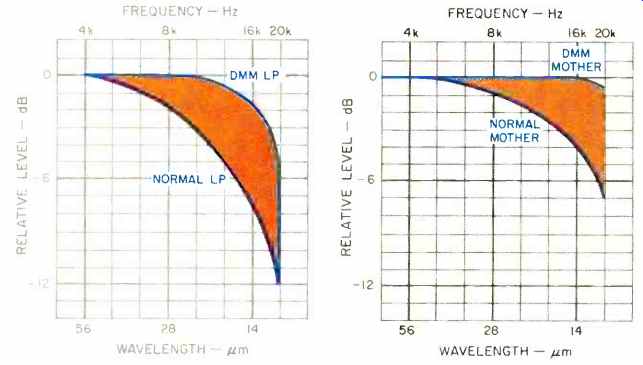

Recording Losses for Small Wavelengths: See Figs. 5 and 6.

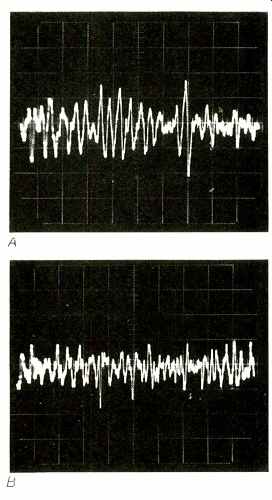

Transient Response: See Figs. 7A and 7B.

------------------

Just as some golden-ear audiophiles continue to tout vacuum-tube equipment, so too are many golden-ears claiming that analog LPs sound far more natural than CDs, despite all the attributes of the CD format. Do DMM LPs live up to the claims made by the recording fraternity? We say yes-with an exclamation point. If any thing, we feel that the claims for DMM are somewhat understated.

On comparing DMM discs with traditionally produced records, we first noticed the extreme quiet in the lead-in grooves and during pianissimo pas sages. The minimal remaining noise is totally free of annoying ticks and pops.

Additionally, there are no pre- or post-echoes on DMM discs, such as can be heard on traditionally mastered LPs.

The suppression of groove deformation noticeably improves the impulse response, so that instruments rich in harmonics remain free of coloration even at high levels. Frequency response ranges from 2 Hz to 23 kHz with extremely little roll-off. (For readers interested in DMM's more technical details, the data presented in Table I were provided by Teldec.)

---Separation of the plated stamper from the metal master reveals the surface

which will actually do the work.

Fig. 3--Noise spectrum of unmodulated groove of a DMM mother (0 dB = 10 cm/S).

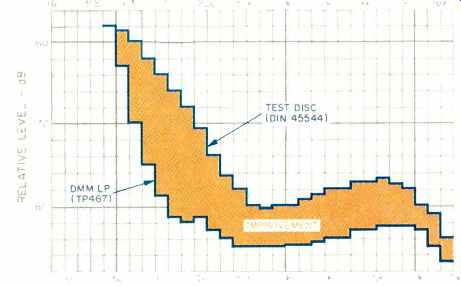

Fig. 4--Comparative noise spectra of test discs cut from lacquer master (top

curve) and DMM master (bottom curve).

About the only negative comment we can make is that occasionally one will hear a slight "edge" or "sizzle" in high-frequency sounds (the same sort that one hears, but more often, on early Compact Discs). This anomaly is easy to put up with, since it generally occurs for only brief periods in most music.

While CDs are superior in their dynamic range, which can go up to 90 dB, the DMMs provide an easily accepted 75 dB (versus less than 60 dB for "old" analog-type records derived from lacquers). It is conceivable that DMM can go a bit farther in dynamic range as more and more companies get involved with it and put their collective minds to extending that range. In the meantime, many music lovers who have been able to make direct comparisons between DMM analog and CD versions of favorite works frequently prefer the DMM analog version.

The DMM process was developed, under the aegis of technical director Dr. Horst Redlich, by Telefunken-Decca Schallplatten GmbH (Teldec) of West Germany, in conjunction with Georg Neumann GmbH, the latter owned 25% by Teldec.

-- Europadisk is also licensed to produce the blank copper masters in

addition to doing the cutting, plating and pressing.

The DMM process is based upon Teldec's pioneering work, done in connection with their videodisc research, to develop a copper deposition, on a stainless-steel substrate, that would be suitable for cutting. The TED disc, introduced by Teldec in 1976, was the first commercial videodisc, and it used the DMM manufacturing process.

Since the initial development of the DMM process, continued research has brought further improvements. In order to meet the requirements for analog audio LPs, an improved copper was introduced. This "Type 2" copper, yielding a signal-to-noise ratio in excess of 70 dB for a 40-micron groove, has been adequate for most types of programs. However, for certain difficult programs (containing large amounts of out-of-phase, low-frequency information) it was desirable to make further refinements, and so an improved cop per deposit was developed which yielded signal-to-noise in excess of 75 dB. An additional advantage has been an increase in the uncut masters' shelf life (re-crystallization time) from several weeks to many months. (This is not a concern once the master has been cut.) Europadisk will now produce both "Type 2" and "Special" copper carriers. "Special" carriers will be more ex pensive than "Type 2" because of an increase in plating time and greater expense in maintaining the electro-forming bath in which the copper is deposited.

Since the introduction of DMM, at least 40 record producers around the world have begun to use DMM equipped lathes. While DMM is only a recent "happening" in the U.S. (where there are more than 20 companies in DMM production, and others about to start), well over 100 million records pressed from DMM masters have been sold worldwide. (Teldec's DMM equipment is imported and distributed in the U.S. and Canada via Gotham Audio of New York City.) Because the DMM processing system differs markedly from that of lacquer-master processing, and the resultant "family relationship" nomenclature is also different, a delineation of those differences is in order.

It is possible to produce only a single negative (the master mold or "father") from each cut lacquer master.

Since a large number of pressing stampers are needed for producing the records themselves, this master mold must, in turn, provide several "mothers" (positive, .playable metal parts), which then create the "sons" (pressing stampers/negatives). The re cord which is sold is therefore actually the "granddaughter" of the lacquer original. A cut copper master, on the other hand, can create numerous "fathers" which may be used directly as the pressing stampers. The purchased DMM record is then a "daughter" of the DMM original. This shorter path not only speeds the process up, but precludes quality deterioration.

===========================

DMM FOR CDs TOO!

LEONARD FELDMAN

[Editor's Note: We are indebted to the Audio Engineering Society, Messrs. Horst Redlich and Guenter Joschko, and to Teldec for allowing us to quote extensively from their preprint (No. 2372) from the 81st AES Convention.-E.P.]

Although CD players are in ample supply (some say oversupply), CDs themselves have not kept pace with demand. This accounts, in part, for the fact that prices of CD players have plummeted faster than anyone would have predicted a few years ago, .but prices of discs have gone down only marginally or not at all.

Among other things, one prerequisite for more economical manufacturing of Compact Discs would be the economical production of masters and stampers for pressing them. To date, laser recording technology has been the only method available for manufacturing CD masters.

This technology makes use of a photoresist method derived from semiconductor manufacturing techniques. Although this technology lends itself to recording and subsequent molding of the kind of signal that is read by laser-beam pickups, it is extremely expensive. In fact, it has been estimated that the investment a re cord company has to make to produce CDs is 10 times greater than that for an equivalent installation to produce vinyl analog records. Part of the increased cost is because all major manufacturing steps must be performed in a clean-room environment. Furthermore, the personnel working in most disc-cutting facilities and pressing plants don't have the back ground or experience needed for this type of technology. Therefore, CD mastering is presently performed in comparatively few locations around the world.

Given these facts, it is not surprising that the most exciting development at the last AES convention was Teldec's announcement that they had extended their system of Direct Metal Mastering (DMM) so that it could be applied to Compact Discs, just as it has been applied to analog LP production, to the earlier Telefunken videodisc, and, more recently, to the RCA SelectaVision videodisc. In short, as Bert Whyte reported in "Behind the Scenes" in February, the Teldec DMM method makes it possible to record information on a CD master in much the same way as it is done on an analog record master-by mechanical means, employing a piezoelectric transducer with a bandwidth of several MHz.

Conventional Disc-Mastering Techniques

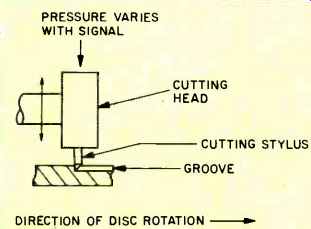

In order to understand the new Teldec DMM system, it will be helpful to review some of the more common methods used to mechanically cut the vertical modulations on analog master discs. (We'll ignore how the analog masters' lateral modulations are cut, since CDs have no lateral component.) Figures B1, B2, and B3 illustrate three different principles. In Fig. B1, the cutterhead is fastened to an arm which moves the head across the disc;

this arm is also pivoted vertically, permit ting it to follow variations in the height of the disc surface. Pressure is applied to the head. While cutting a stereo groove, the pressure is varied by the signal so that the groove's depth is proportional to the signal's amplitude. This will prevent the stylus from rising out of the groove when heavy vertical modulation increases its vertical travel in relation to the cutterhead.

Fig. B1--In this analog disc-cutting system, groove depth is controlled

by pressure applied to the cutterhead.

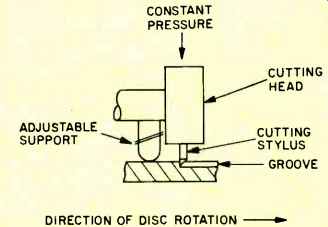

Figure B2 shows an older arrangement.

Here, the pressure is applied so that an adjustable support (the "advance ball") rests on the surface of the blank disc. The cutterhead follows the medium's surface, and the groove depth is determined by the support's height relative to the adjacent cutting stylus; vertical adjustment for groove amplitude is accomplished within the cutterhead. This method and the one described above are used primarily for recording phonograph discs.

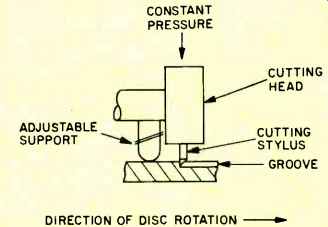

Figure B3 shows a cutting system for high-density storage, such as videodisc recording; it was used to cut grooves only 0.1 µm deep for the Teldec and RCA videodisc systems. In contrast to the other two arrangements, the cutterhead is held at a fixed height. Since this prevents the cutter from following motions of the disc's surface, its height is set so that the tip of the cutting stylus will always be below that surface. Thus, more material than necessary is removed in the cutting process, generating an entirely new surface. Here, the groove depth depends only on the height of the cutterhead; the groove width depends upon the groove depth and the included angle of the bottom facets of the cutting stylus tip. While this method allows very high precision, it is applicable only if the distance between grooves is constant and if no "land" is required between adjacent groove segments. Neither of these requirements is met by the CD format.

Fig. B2--1n the "advance-ball" method, groove depth is controlled

by the height of the adjustable support.

Fig. B3--In this system, used for videodiscs and other high-density recordings,

the cutting head is set at a constant height; the stylus cuts away the original

disc surface to create an entirely new surface.

Mastering the Pits

The pits on a CD can be thought of as constituting a spiral groove which is interrupted according to the digital data stream applied. In other words, it consists of very short groove segments of different lengths. At first glance, one might think that the arrangement of Fig. B2 could be modified for this type of recording. That is, the difference in height between the sup port and the cutting tip could be adjusted so that the cutter would dig into the surface when a pit was required and lift off the surface when a land or absence of pit was called for. Unfortunately, because of Fig. B4-In the DMM system, the expansion and contraction of a piezoelectric transducer raises and lowers the cutting stylus rapidly, creating pits in a CD master.

the microscopic dimensions of the pits involved in the CD format, it is a practical impossibility for the support to follow variations of the disc exactly without causing damage to the surface structure.

Figure B4 illustrates a possible solution to the problem. A piezoelectric transducer has a cutting stylus attached to it. When a positive potential is applied to the upper electrode and a negative potential is applied to the lower electrode, the piezo electric element expands (as shown at the left). Conversely, with reverse potentials applied, the piezoelectric element con tracts (as shown at the right). The force needed to produce this dimensional change is very great and is generated by an electrical field. The assembly rests on the disc, and the cutting stylus enters into its surface due to gravity. The gravitational force required to cut sufficiently deep into the surface of the disc is very small. Since the piezoelectric element contracts more rapidly than gravity can shift the cutting stylus, the stylus lifts off the disc temporarily. The pulses are so short that the stylus does not have time to fall to the disc's surface during a negative pulse. Instead, it cuts into the disc during a positive pulse, generating the desired pattern of pits in the master.

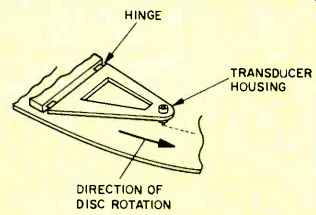

Fig. B5--A resilient plastic housing holds the piezoelectric transducer

in position while accommodating the transducer's changes of shape.

Fig. B6--A DMM cutter assembly for Compact Discs, showing the transducer

housing and floating support.

Of course, the piezoelectric element can't be suspended in midair and held at its center of gravity, so a support (shown in Fig. B5) was developed. The transducer element is embedded in a plastic material which is soft enough at the operating frequency of the transducer to permit the expansion and contraction described. Effectively, this plastic structure provides a "floating" support. The complete assembly takes the form shown in Fig. B6. The floating transducer is mounted in a triangular bracket which is secured on one side and is free to move in a vertical direction. The tip rests with some of its weight on the disc. Dynamic parameters of the assembly are carefully sized so that the housing of the floating transducer follows vertical changes in the surface of the disc over a range of several µm.

Embossing Rather Than Cutting

Using DMM to cut pits into the surface of the CD metal master creates a problem:

The chips created by the cutting are too small to be vacuumed off the disc surface during cutting (as is done when cutting analog masters). Teldec therefore suggests embossing the signal pits into the surface of the master disc, rather than cutting them in. The diamond tool attached to the piezoelectric transducer is of a different shape for embossing than for cutting. Although pits generated by the embossing process create a different modulation of the reflected laser beam as received by the optical system during playback, the method fulfills the most important prerequisite for Direct Metal Mastering technology as applied to the compact Disc, namely full compatibility with conventional CD players.

Making a DMM CD Master

Since a metal surface is used as the original recording medium, final pressing tools or stampers can be generated directly in a galvanic process without any intermediary steps. A round glass disc is prepared with a thin separation layer. A layer of copper approximately 300 nanometers thick is evaporated onto the disc.

The pits are recorded onto this copper surface as previously described. Because the pits are generated directly, it is possible to control them more accurately than is the case with the photoresist/laser cut ting method used until now.

Once the copper layer is embossed with the required pit pattern, the copper surface is coated with a thin layer of precious metal. This metal package is then reinforced in a nickel bath until a thickness of about 0.25 mm is achieved. The metal package can now be used as a "father" (from which "mothers" and stampers will be produced) or, if the number of CDs required is not too large, the package can itself be used as a stamper, good for anywhere from 10,000 to 15,000 pieces. In the latter case, according to Manfred K. Atzert, managing director of Teldec, CD pressing can begin within about two hours after completion of the mastering process.

The thin separation layer on the glass disc allows the metal package to be re moved easily from the glass, which can be used again. The recording itself is completely protected between the copper and precious-metal layers. This galvanic "sandwich" technique therefore provides an excellent and safe medium for storage and shipping.

The last step in the DMM-CD process is the release of the electroplate from the sandwich. Both the separation layer and the copper layer consist of non-precious metals, so it is fairly simple to remove them without damaging the precious-met al surface on the nickel backing. Then, using the metal backing as a "father," more "mother" and stamping tools can be manufactured using the same galvanic process.

Breaking the Cost Bottleneck

Teldec, in describing this new technique, cited five major benefits that accrue from the DMM-CD method. First, the expensive clean-room environment is not required when making a master recording. Accordingly, less physical space is needed for the mastering process. There are fewer production steps, and production is therefore more efficient. A faster turnaround is possible, which should help make the number of CD titles equal to the number available in black vinyl in a shorter time period. Finally, the entire pro cess is easier to handle. It all adds up to a lower investment for the software makers.

So if you have been holding off on the purchase of a CD player because of un availability of your favorite records in CD format, you won't have this excuse to fall back on for quite as long as you may have supposed. Ali of which bodes well for the future of audio, graphics, video, and text data storage in the CD format.

===========================

------------

Table II-Standard data of DMM technology.

Maximum Recording Level: As for lacquer cutting Maximum Groove Width During Modulation: 180 µm.

Cutting Stylus Utilization Period: 20 LP sides per re-polishing.

Cutting Stylus Life Time: 50 re-polishings, minimum.

Storage Time of Copper Blanks Before Recording: 3 months.

Storage Time of Copper Master After Recording: No limit.

Number of Stampers by Direct Matrix: 20, minimum.

Number of Stampers by Three-Step Plating: Equivalent to standard processing.

Groove Integrity: High, due to fact that formation of "horns" is completely avoided.

-----------

To permit the previously mentioned "father" to be made from a lacquer, its surface must be made conductive and this process must not alter the modulated grooves. The conductive surface (of silver) must be extremely thin and must not attack the lacquer surface.

Furthermore, the silver molecules must be evenly applied to minimize the creation of impulse-type interference, which can no longer be corrected.

Nickel is plated onto the silver surface, and this can seriously deform the grooves in the lacquer through mechanical stress. Therefore, the mastering engineer must make the groove walls thicker than really necessary be cause of the instability of the lacquer coating, on the one hand, and the danger of deformation resulting from the nickel-plating process on the other.

This reduces playing time. But despite this precaution, pre- and post-echoes are still audible in classical records.

The metal cutting surface of DMM avoids all of these disadvantages. For the tape-to-disc cutting room, DMM provides a distinct advantage: The 20% rejection rate which has been traditional in lacquer cutting and subsequent plating is reduced to less than 2% with DMM. Further, the 10 to 20% rejection rate in choosing lacquer discs suitable for cutting is bypassed.

The overall DMM system is a complex one, involving many interrelation ships among chemical, thermal, electrical, electronic, and mechanical processes as well as human judgment factors. We'll attempt to delineate them by recounting what we learned during a trip through the facilities of Europadisk, in downtown Manhattan. Our guide was James P. Shelton, the company's president. (For additional de tails, see Table II, provided by Teldec.) Before the tour got underway, we were told that Europadisk is, in effect, a "one-stop" operation in that it is licensed for all DMM processes-mastering, plating, and pressing, as well as the production of master discs (copper blanks) for use by Europadisk and other DMM licensees. In fact, Europadisk is the only source in the U.S. and Canada for the copper master-disc blanks.

(Of course, they can also be bought directly from Teldec.) To earn the right to place the DMM logo on a record album, a record company must have all the DMM work done by licensees, such as Europadisk.

The first thing that Shelton pointed out was the "clean-room" ambience typical of well-run establishments producing high-tech products. "It's only natural," he stated. "If you've seen the clean-room surroundings where digital Compact Discs are produced, and if you want to compete with the CD people, you should be as good as they are in terms of your own production facilities or even better. Maintaining a clean operation means that the possibility of record-groove contamination in cut ting, plating, or pressing is almost eliminated." The main area that we visited was the cutting room, where the required equipment was housed. It included a Neumann VMS 82 cutting lathe with an SX 84 cutterhead, a TV monitor for viewing the cut groove, SAL 84 cutting amplifiers, and a variable pitch and depth computer. Some DMM licensees utilize VMS 80 cutting lathes, which can be upgraded, if desired, to VMS 82 equivalents.

[left] Fig. 5-Comparison of frequency response for small wavelengths on LPs

pressed by Teldec from lacquer and DMM masters, at 130-mm groove diameter,

using Shure V15 Type V cartridge. [right] Fig. 6-Same as Fig. 5 but for playback

of DMM and normal (lacquer) mothers.

The SAL 84 amplifier drive system used for DMM is completely free of transformers. The frequency response of the system extends to 2 Hz on the low end. This expansion of the frequency response by about two octaves (compared to the older lacquer system) is not meant for cutting signals in that portion of the spectrum but rather serves to linearize the phase response in the audio range, which lies quite a bit above this frequency. The practical result is significantly higher feedback at low frequency, thus improving the phase response and also improving crosstalk between channels.

Phase shift at 20 Hz is less than 20°, and stereo separation at 100 Hz is greater than 30 dB. At the high end of the spectrum, the frequency response extends to 23 kHz, with a gentle roll-off above that.

-------- Here the stamper is being center-punched for an accurate location

on the pressing machine.

Separation between channels below 100 Hz is also much better than lacquer, due to differences in the DMM lathe's electronic control system. The conventional cutterhead suspension, engineered to appear stiff at frequencies above 20 Hz, allows the cutter-

head to float at frequencies below that point in order the surface of the master blank. Unfortunately, this floating effect reduces channel separation at low frequencies.

In DMM systems, special circuitry applies a counteracting depth-control force which is in proportion to the low-frequency signal amplitude. The result is that the cutter remains stiff for all audio signals, even below the suspension resonance point. This yields 20 dB of channel separation to 20 Hz and lower, which is far superior to conventional lacquer cutting. In fact, the low-frequency stereo separation is one of the first things people notice about DMM masters.

Fig. 7--Mothers from lacquer (A) and DMM (B) masters. Note rounding off of

transients in (A) due to heating and burnishing facets required for lacquer

masters. Sharper transients in (B) result from "feather edge" on

DMM cutting stylus.

----- The last step before mounting the stamper in the record press is

to form its shape so that the proper record profile will then be pressed.

DMM technology is centered on the ability of the Neumann cutting lathes to cut into a 4-mil-thick (100-micron) coating of amorphous copper layered onto a 300-mil stainless substrate, in stead of the traditional aluminum lacquer-coated disc. Shelton explained that cutting copper masters is substantially different from cutting those with a lacquer coating. The material is much harder and is five to 10 times more resistant to the cutting stylus than lacquer. "It would be impossible to cut a copper disc at 20° off perpendicular, the angle that is appropriate to lacquer mastering and which is the standard for playback tracking relative to consumer phono cartridges.

The stylus would 'ride' the groove it was cutting, in effect not cutting deep enough. Therefore, Teldec designed the VMS 82 to cut a master at a near-0° angle-about 5°." This approach reduces the required cutting force to an adequate level so that the cutter needs only normal cutting-amp power. Essentially, the rotational force of the VMS 82 turntable is concentrated against the face of the cutting stylus, attempting to break it rather than to push it up and away from the master surface.

Helping to keep the rotational force within normal cutting-amp power limits is the shape of the new Teldec diamond cutting stylus (Fig. 1). This stylus has no burnishing facets and thus avoids the high-frequency amplitude losses that occur at the innermost grooves of LP records.

While a 5° cutting angle is employed, the IEC standard playback angle for consumer phono cartridges is 20°, and this must be factored into the DMM process. In addition, the grooves must be cut to meet that standard; other wise, playback would be severely distorted. Teldec gets around this dilemma by adding a tracking-correction element to the cutting signal. Said Shelton, "The deviation from the usual value of the vertical tracking angle is corrected by means of an electronic delay equalizer that is part of the system's electronics. It is called a Vertical Tracking Angle Converter, and it provides the correct playback angle for a typical phono cartridge through time delays." Shelton went on to explain that there is a marked difference between the styli and between the procedures used in cutting lacquer masters and DMM masters. "In creating a lacquer master, the sapphire cutting stylus must be heated to reduce hiss noise during cut ting. The recording engineer must strike a compromise between too little and too much heat. Too little increases noise, while too much erases the highest frequencies as they are cut and generates 'horns' [crests on the groove edges]. Horns degrade the quality and complicate the production of stampers, and create molding problems at the record press that lead to waste and higher production costs." Styli designed for lacquer cutting in corporate burnishing facets which smooth the groove wall for a quiet cut (Fig. 2) but also erase and distort high-frequency content on inner diameters.

By employing copper material, eliminating cutting-stylus burnishing facets and doing away with stylus heating, the DMM process avoids the horns that can cause the clicks common to lacquer mastering. This simplifies both plating and pressing of DMM product, since the costly and potentially de grading horn-removal treatments (polishing/buffing) used in lacquer master production can be bypassed.

--- Actual pressings of standard LP discs can be out of the press in

less than two hours following cutting of the DMM copper master.

Fig. 8--Rumble recorded on a standard LP test record (A) and DMM test record

(B). Records are DIN 45544 and DMM TP467, respectively.

Although copper as a mastering medium presents significant advantages, it also presents difficulties to the master-cutting lathe, Shelton observed.

"Despite its apparent hardness, cop per exhibits a viscous-like behavior in regard to cutting tools, tending to stick to them. Teldec has overcome these difficulties by imposing supersonic vibrations (mechanical chatter) in the 60- to 80-kHz range on the cutting stylus, which has a feather edge. The ultrasonic oscillations also ease the movement of the cutting stylus through the copper carrier. This action, similar in basic principle to ultrasonic cleaning, separates the copper chip residue from the diamond cutting stylus and results in a smooth, gleaming, high-definition groove wall that guarantees a high signal-to-noise ratio." It is important to note that while the DMM process is beneficial to performing artists and the listening public, it also holds important economic advantages for record manufacturers. In fact, several of the largest European pressing plants have converted completely to DMM and no longer accept lacquer masters. The economic benefits include the following:

The expensive, complicated, and hard-to-control silvering and nickeling processes required for lacquer masters are completely eliminated. Savings in the plating process alone amount to between $40 and $60 per record side;

The 20% rejection rate common in lacquer master production is reduced to less than 2%;

Twenty or more stampers can be made directly from a DMM master, with no reduction in sound quality. Considering that an average stamper has a life of 1.500 pressings, the DMM pro cess is particularly economical for re leases of up to 30,000 LPs: and First pressings can be made in less than two hours after conclusion of the cutting process.

Shelton pointed out that, during the cutting stage, the Neumann VMS 82's computer translates the preview cut ting signal into lateral and vertical (groove width and depth) signals for control of depth and pitch. This precise control increases the potential for additional grooves per record side. In operation. the computer is. in effect. sampling the preview signal and then storing, summing, and calculating the next groove position. Often the "land" space between grooves can be reduced remarkably, to a width of virtually zero, permitting recording times of up to 40 minutes per side. Additionally, since the cutting-depth corrections are necessary only for short. lateral signal bursts. the DMM system permits cuts with a smaller basic groove depth than in the lacquer mastering process. for better transient response and greater dynamic range.

Shelton said that an attribute of interest to record producers is that after DMM mastering and a protective process called "passivation," the cut-cop per discs have a virtually unlimited shelf life because the amorphous cop per surface returns to its original crystalline state. "On the other hand," he added, "the optimum time to plate a lacquer disc after cutting is more on the order of a few hours. Otherwise, high-end losses may occur, in addition to pre- and post-groove echo. If a lacquer master is not plated within one week, it may have degraded to such a point that it is not feasible to plate it." In a parting comment, Shelton declared, "No matter how much time and care and effort you put into mastering--be it lacquer or state-of-the-art DMM copper-the ultimate record quality hinges in large part on the quality of vinyl used in the final stage. Here at Europadisk, for our 'Ultimate Audiophile' designation, we use at least 150 grams of virgin Teldec vinyl to make a dense. elegant pressing at least 30% heavier than ordinary records. It's equal or superior to any LH pressing made anywhere." The firm also offers two series weighing in at 130 grams, one called "Audiophile" and the other "Europa-Classical." Both use Teldec vinyl.

Notwithstanding all the recent gains in phonographic technology such as digital sound, DMM, and the Compact Disc, the audio industry has not been able to annihilate an old bugaboo that has plagued records since their ad vent, first as Edison cylinders then as flat Berliner discs. et al. That bugaboo is none other than dirt and grime.

Whether one opts for standard analog, DMM. or CD, there's no choice but to keep those discs clean!

(Source: Audio magazine, Apr. 1987)

Also see: Direct Cut Myths and Problems, by Adrian Hope--A visit to Teldec, examining prospects for the D-to-D phenomenon. (1979)

= = = =