Article author: Herman Lia [Senior Engineer, Dept. of Magnetic Research & Development,

Tandbergs Radiofabrikk, A/S, Oslo, Norway]

This article describes a new recording system which has been developed by the Department of Magnetic Research & Development at Tandberg. As this system will be able to utilize the new generation of metal particle tapes, an overview of the merits of such tapes are also discussed in the context of future tape recording technology. This new recording system is called Actilinear, and patent applications have been filed and patents are pending.

The development of recording technology is being carried on in two separate and different groups: Manufacturers of magnetic tape represent one environment, and manufacturers of recording machines the other. Development in this connection is defined as the effort on the part of both parties to come up with better products for the consumers with regard to technical specifications, reliability, ease-of-operation, etc.

The development has traditionally been such that first the tape manufacturers bring new concepts to the market with properties that promise improvements over the existing state of the art. Then the machine manufacturers examine the nature of these improvements and how these can be used to advantage in the various types of recorders. Lately, however, a good collaboration has been established between these two groups, and this will naturally lead to better compatibility between the tape and the tape recorders. The greatest benefit of such a collaboration lies in the fact that the machine manufacturers will be able to include the advancement of new tape technology in an early phase of new product development.

If we look at the development of magnetic tape in the last 15 years, we find a clear trend towards higher saturation flux density, Bm, and higher coercivity, Hc. This has been a natural development based on a desire for a continuous improvement of the signal-to-noise ratio. In particular, it was an immediate requirement with the introduction of the compact cassette, since there was no opportunity to select track width and tape speed.

An increase of the Bm gives a better signal-to-noise ratio at lower and middle frequencies, whereas a higher Hc gives a better signal-to-noise ratio at higher frequencies. The first compact cassette that was introduced contained tape having Hc = 250 Oe. Then we had the so-called LH tape (low noise, high of tout) having Hc_ = .(C 0e. Later we go= th_ C 4)2 level tapes ',with -1, = 550 e (e.g TDK SA and Maxell UD-XL II). Ect th s cces not end the development. We Lnow that experiments are going co today with tapes having g Hc = 1000 Oe, and these are certain -o came on the ma-ke*. in the near future.

In the midst of this development, a central question for the serious recorder manufacturing company is to what degree the present recorders will benefit from the new types of tape which will come on the market within a relatively short time.

These are questions which gain momentum as new concepts from the magnetic tape industry are being marketed. We presently have recorders with selector arrangements which make it possible to choose between different types of tape, but only among the ones already on the market. Obviously, it is a hopeless task to design a recorder today which will give optimum performance with any type of tape five years from now. What can be done now, however, is to prepare the ground in the best possible way to allow for the possibility of adjusting the recorders to new types as they appear on the market.

Consider a tape with Hc = 1000 Oe which today is in the experimental stage, but which quite certainly will be commercially available in a year or less. Unless we are ready to take these new tapes into account now, we will end up in the same situation we had when the CrO2 tapes came on the market, when there were no cassette recorders to take the full advantage of them. Of course, the recorders then were not adjusted to these types, but the fact that they did not have even a 3-dB margin in bias-and recording currents such that they could have been adjusted is a clear testimony to a lack of a progressive design philosophy at that time.

One can learn from errors, however. The tendency today is towards a far greater ability to provide headroom and adjustments, and there is a desire to bring advanced design concepts into realization. This has, in fact, been the guiding spirit in the development of the recording amplifier chain in the new Tandberg tape recorders, for compact cassette as well as open -reel recorders.

Conventional Recording Systems

The conventional method of designing a recording amplifier is well known and will not be dealt with in detail. We will just note that the summation of recording current and bias current in the recording head is done through passive components, and this leads to compromise solutions which have their distinct and pronounced weaknesses.

The following difficulties should be mentioned 1) small headroom margin, 2) slew rate limitations for strong signals and high frequencies which results in intermodulation, 3) poor isolation between oscillator and recording amplifier which results in interference tones, and 4) too low a margin in bias and recording currents for readjustments to adopt to the new high coercivity tapes.

The New Recording Chain

With the development of the new recording system we have left behind and abandoned any form of compromise solution. The new design philosophy is based on the optimization of modules, that is, the whole chain is divided into natural functions, and each function by itself is realized as a module. Hence, a solution is obtained which is optimum on all points at the same time as a system is realized which is more amenable to adjustment to new types of magnetic tape.

The new recording amplifier chain is shown in Fig. 1.

The Particular Functions

The equalizer module: This amplifier will give the recording chain the proper frequency equalization such that the overall frequency response of the recorder becomes as linear as possible. The C2,R4 network gives proper equalization at low frequencies, whereas R2, R3, C1, L1 gives the desired equalization from mid-frequencies and up.

Internal adjustment of recording sensitivity: This is simply the potentiometer R5 and provides an internal sensitivity adjustment of the recording signal.

Fig. 1 Block diagram--schematic of the Actilinear recording amplifier

chain.

The transconductance module: This module has two main functions. It converts a voltage from the potentiometer R5 to a current is which is the recording current. It shall also provide an electrical isolation between the oscillator and the recording amplifier such that interference tones are avoided and completely eliminated.

The circuit consists of the two transistors Q1 and Q2. Q1 is used in a common -emitter configuration, and it has Rg = 12 kilohm and Q2 as a collector load. Advantage has been taken of a special property of transistors in that the collector can appear as a low resistance to d.c., but a high impedance to a.c. signals. The two collectors are connected at point P. This point is put at 12 V d.c. and can swing between 2V and 22V, and thus has a maximal dynamic range available for driving current is through the head. The d.c. current through Q1 and Q2 is about 10 mA so that each single transistor represents the equivalent of a resistance of 12 V/10 mA = 1.2 kilohm at d.c. The output impedance for a.c. signals, however, is 1/hoe = 20 kilohm for each transistor and, hence, the total output impedance seen at point P is approximately 5 kilohms. Since the recording head impedance is substantially less than 5 kilohms (200 ohm at 20 kHz), the circuit acts as a current source, that is, a constant voltage at the input gives a constant current is through the recording head. This is also the justification for the name Transconductance Amplifier.

Any residual oscillator voltage at point P is being prevented from being fed back to the input by C5. This way the circuit provides an electrical isolation between the equalizer amplifier and the oscillator.

Filter Module: The filter module prevents oscillator signals at point R from entering into the point P and interfering with the audio signal. At point R Uosc = 20V, but is reduced to about 50 mV at point P. The filter is of the low-pass type with a trap at 123.5 kHz.

Calculation of Headroom Margin in the Recording Amplifier

Since the recording amplifier is designed as a transconductance block, the limitation in headroom is determined by the maximum available current in the output stage. This is actually the quiescent current in the two transistors Qi and Q2, and is set to IQoc = 10 mA. The maximum available a.c. current is then IQpc = 2\. The headroom margin is the ratio between this current and that which is necessary to record the tape to maximum recording level ism. Therefore, we have:

*Where HRM is an abbreviation for headroom margin.

Numerical calculations with IQpc = 10 mA and ism = 0.4 mA gives HRM = 19 dB.

Calculation of the Slew Rate

The slew rate of an electrical signal is defined as the time derivative of the amplitude and is determined in Volt/µS or Volt/mS.

Let: e(t) = Em sin wt, be a general signal with angular frequency w and amplitude value Em.

The slew rate is given then by:

The maximum slew rate occurs when the term cos wt has its maximum value which is 1. That gives the usual formula S = w Em. As an example, we will carry out the numerical calculations for the TD 20A (the new series of Tandberg reel-to-reel tape decks).

The impedance of a recording head is almost pure inductive at audio frequencies and can be expressed by ZH - wL where L is the inductance of the head. The maximum signal voltage across the head occurs at the maximum recording level and is given by eHM (L) = wL ism where ism is the maximum recording current. Let e(t) = Em sin wt.

The slew rate of the signal voltage across the recording head is determined by the following calculations:

where, fo = 20 kHz, L = 5 mH and Ism = 0.5 mA, then SH = 4 V/mS.

The maximum slew rate which the recording amplifier is able to handle is according to measurement equal to 400 V/mS. That gives a slew-rate margin of 40 dB which is a satisfactory figure.

Conclusion

A new recording amplifier chain has been designed which will be implemented in the new Tandberg cassette recorder, as well as open -reel machines. Improvements relative to conventional designs can be summarized as in the following:

1. More headroom in the recording amplifier, greater than 18 dB.

2. The recording circuitry operates at a lower voltage level and will, therefore, give less intermodulation because of slew rate limitations.

3. An improved electrical separation between oscillator and recording amplifier which gives less interference with the oscillator.

4. Substantially greater possibilities of adjusting the recorder to new high coercivity tapes such as the new metal particle tapes.

-----------------------

Gains Using Metal Particle Tapes

As we have presented the new recording amplifier which is especially suitable in connection with high coercivity tape, we take the opportunity to carry out calculations for such a tape as an example. The most important figures to note are the S/N ratio at low and high frequencies and the total signal capacity integrated over the entire audible frequency range.

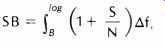

The S/N ratio at low frequencies is proportional to the maximum remanence flux density, Br, in the tape and the coating thickness, d. At high frequencies, the S/N ratio increases proportional to the coercivity force, Hc. To determine the signal capacity, we use Channon's definition:

where S is the maximum obtainable signal and N is the tape noise. For further details into this matter we refer to an earlier article in the Audio (April, 1977), where all relevant formulas for these calculations are stated.

To get an idea of the improvement with the new tape, the results are presented relative to the Maxell UD which is one of the most popular types of tape used today. In the following table are listed the most important physical properties and the calculated figures for S/N ratio.

The improvements have been verified by measurements on a sample received from the 3M Company a few weeks ago.

The measured values agree with the calculation with an accuracy better than 1 dB.

This new tape, as seen, is certain to present another dramatic improvement in tape recording performance levels, and particularly in the compact cassette format. Tandberg has plans to introduce recorders that include provisions for the usage of metal particle tapes as soon as they become commercially available.

Tape Qualities -- UD -- UDXL-II -- Metal Particle

Retentivity Br (Gauss) 1430 1540 3400

Coercivity H, (Oersted) 360 545 1030

Coating Thickness (pm) 5.0 5.5 3.8

S/N Ratio at 333 Hz * (dB) 0 +1.5 +5.7

S/N Ratio at 10 kHz * (dB) 0 + 3.6 +9.1

Signal Capacity * (dB) 0 +3.0 +8.5

*With reference to the Maxell UD.

-----------------

(Source: Audio magazine, July 1978)

= = = =