Manufacturer's Specifications

Type: Two speed.

Motor Type: Direct-drive, quartz-locked, PLL Hall-effect.

Platter: 12.2 in. (31 cm) dia. aluminum alloy die-cast.

Wow and Flutter: Less than 0.013 percent W rms.

S/N: Greater than 78 dB (DIN B).

Speed Deviation: Less than 0.002 percent.

Speed Drift: Less than 0.00008 percent/hour at 33 1/3 rpm; less than 0.00003 percent/degree at 33 1/3 rpm.

Time to Reach Full Speed: 0.6 S, less than 120 degrees rotation.

Tonearm Type: Linear motor direct-drive, tangential tracking, static balance.

Length: 7.5 in. (19 cm).

Overhang: 0 in. (0 cm).

Height Adjustment Range: ±0.12 in. ( ±3 mm).

Headshell Weight: 10.5 g.

Usable Cartridge Weight: 4 to 14.5 g.

General Specifications

Power Requirements: 120 V a.c., 50/60 Hz, 35 watts.

Dimensions: 19.4 in. (49.3 cm) W x 6 in. (15.2 cm) H x 17 1/2 in. (44.5 cm) D.

Weight: 26.12 lb. (12 kg).

Price: $750.00.

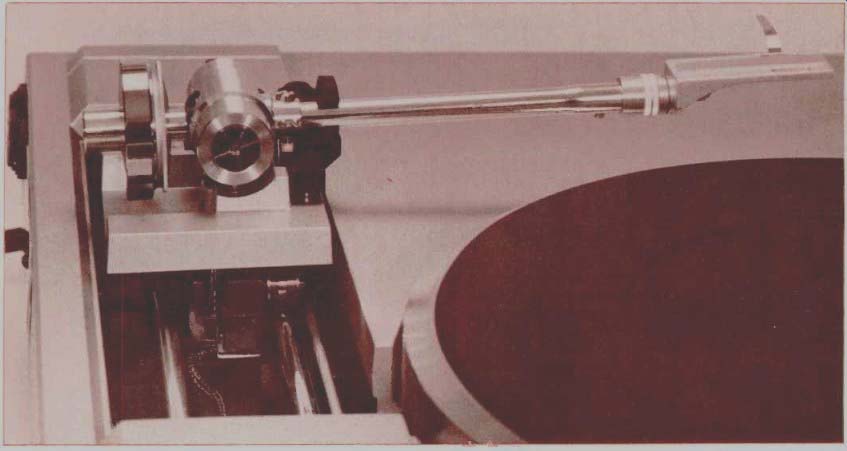

Linear, or straight-line, phono tracking has long been the engineer's dream, and many attempts have been made to translate the idea into practice. Early models were not too successful as they merely replaced one source of distortion with another, but the use of modern technology with optical sensing has enabled designers to come up with at least two well-engineered models during the past few years. Phase Linear's 8000 Series Two turntable also employs optical sensing to keep the cartridge in the groove, but there's a difference. Instead of an ordinary drive motor, the arm is driven by a linear induction motor. The coils are positioned horizontally in a straight line, while magnets are mounted on the arm base. When a current flows in the coils, the arm is impelled along a rail--so there are no gears or linkages of any kind.

As the stylus tracks the record groove, lateral deflections move the arm slightly towards the record center. If the movement at the stylus tip is not matched to the arm base, the unequal stress would result in mistracking and consequent distortion. However, the optical sensor prevents this by sending correction signals to a differential amplifier controlling the motor. The manufacturer points out that this system is sensitive to deflections from either side, and therefore warped records present no problems.

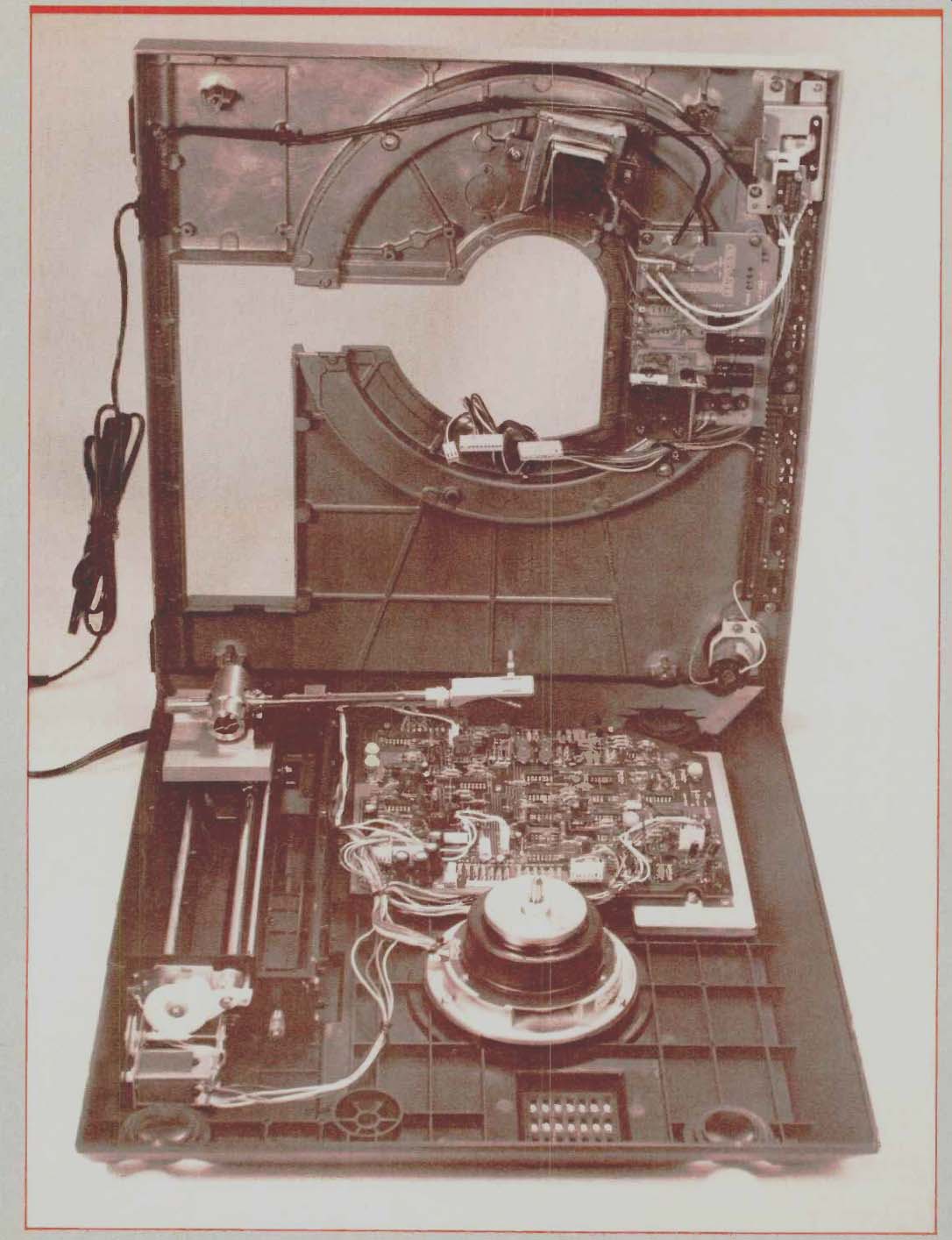

A separate d.c. motor is employed to control the cue-lift function, and no less than 11 ICs are used in the command link to the front-panel controls. The turntable drive motor itself is a "hanging rotor" type similar to the Pabst "inside-out" design where the coil assembly rotates instead of the motor shaft. It makes use of the Hall-effect principle and is quartz-controlled with a PLL circuit.

The unit is somewhat larger than most, measuring 19.4 inches wide, 171/2 inches deep and 6 inches high. The arm, which is made from highly polished aluminum, slides along two parallel rails at the rear. A counterweight and calibrated ring enable it to be balanced in the normal manner, and there is a locking clamp over on the right-hand side. Distance from pivot to stylus is only 7.4 inches, thus increasing the strength-to-mass ratio. A large control knob on the front pan el allows the arm to be moved to the left or right, while to its left is the Start/Stop switch and the cue lift button. Then comes another push button for Repeat, and way over on the extreme left is a group of three buttons for speed (33 or 45 rpm), disc size, and on-off. An indicator light next to the speed switch shows when the quartz PLL circuit takes over. All controls are accessible when the dust cover is closed, and the cover is specially shaped to accommodate the large arm control knob.

The unit stands on four adjustable isolating feet. Because of the unique design, accurate balance is essential, otherwise the arm tends to slide one way or another. To facilitate level ling, a large flat spirit level is supplied; this is not intended to go on the motor board but on the actual arm rails--which, of course, makes more sense!

All Phase Linear products are styled in a distinctive no nonsense way, and the Model 8000 is no exception. The aluminum top panel is finished in a satin silver, while the push buttons have neat brown surround trim, giving the unit a modern, streamlined appearance.

Measurements

For test purposes, an Adcom XC-E moving-coil cartridge was mounted on the detachable headshell, using the gauge supplied. Next, the isolating feet at the base were adjusted so the unit was perfectly level, and the tracking force was then set to one gram. Arm height is adjustable but I did not find it necessary to change the setting, and, of course, there is no anti-skating control to bother with.

The first test was for wow and flutter, and the figures were near the limits of the test records at 0.03 percent. (DIN 45 507). Rumble was as low as I have yet measured at-63.5 dB, using the ARRL weighting method. Tracking error was zero (no surprise there), and arm resonance with the Adcom cartridge was at 8 Hz with a rise of 2 dB. Speed was right on the nose, and I should mention that there is no variable control.

Arm friction was very low indeed--especially in the lateral mode where, as already noted, a slight imbalance would cause the arm to move. Tracking force was set to one gram which was sufficient to track all sections on Shure's ERA--III test record and all bands on ERA IV. The lowest force possible with this cartridge on the best "ordinary" arm was 1.25 grams.

In-Use Tests

At the end of a record, the arm would lift and return to its rest, taking about six seconds (sensing is optical). To begin a disc, it can be moved manually, or the start button could be depressed and the arm would take the cartridge to the record and gently lower the cartridge to the run-in groove. Another method--which I preferred--is to use the front-panel remote control to place the arm where required and then press the cue button. If this happens to be in the down position, the arm cannot be moved this way, so there is no possibility of the stylus hitting the edge of the platter. The cue lift arrangement is obviously quite expensive to manufacture but it does work extremely well, and (predictably) there is no backlash whatsoever.

The only criticism I have concerns acoustic feedback, as I found it necessary to use separate isolating feet to cure this completely. However, in all fairness, the loudspeakers are not very far away, and this has occurred with many other turn tables.

To sum up: The Model 8000 Series Two is very well-engineered, beautifully made, and a joy to use. While not inexpensive at $750.00, this turntable achieves very high levels of performance, including a best-ever measurement for rumble. It should also be pointed out that tracking all bands of the Shure ERA--IV test record is first-rate performance for any arm-cartridge combination. All in all, then, the Phase Linear 8000 Series Two can be recommended as one of the best designed and manufactured turntables available presently.

-George W. Tillett

(Source: Audio magazine, Nov. 1980)

Also see:

Phase Linear--Phase 8000 turntable (ad, Oct. 1979)

= = = =