By Carl Babcoke, CET

---------

Unusual Information about Capacitors:

Some types gradually in crease in capacitance over the years. Others have decreased capacitance with age. Do you know examples of each? A capacitor can operate too warm and then short, although it is subjected to less than the rated voltage. What conditions can cause such failures? Some capacitors repair their own shorts. Can you name the type? Many capacitors can regain as much as 8% of the original voltage after they are discharged. What is this called, and how can it be a problem? Which type of capacitor undergoes a change of capacitance from the applied voltage or the signal frequency? Which kind of capacitor never should be used as a replacement? Why?

--------

Technicians today are offered a broad range of capacitor types for replacement uses. In fact, so many kinds are available that selecting the best type can be a serious puzzle. The information you need about capacitors is compiled here.

No single type of capacitor is best for all uses. None is perfect.

Therefore, for each replacement, you should select the one type that provides the characteristics most needed, but without serious draw backs. This is not a depressing situation. Instead, it gives you the opportunity of reducing call-backs and providing superior operation of the products you service.

Capacitance

Few capacitors have the exact rated capacitance when first manufactured. All are rated in percentage of error. What's more, their capacitances are subject to drift or variation from aging effects, temperature changes and the amount of applied voltage or frequency.

The amount of change from these conditions depends on the construction of the capacitor and on the materials used (particularly the dielectric). Therefore, we need to know the effects of the various kinds of dielectric materials, plus the other specifications that deter mine the suitability of replacement capacitors.

Paper dielectric

Paper-dielectric wound capacitors are constructed by rolling long layers of material into a tubular shape. There are four layers. One is thin metal for one plate, next is a layer of waxed or oiled paper for a dielectric, another plate of thin metal and finally a second layer of paper. The plates are offset so they can have wire leads attached to them. Finally, a sealing coat of plastic is placed over the body.

Paper is not used anymore as a dielectric because it invariably had defects and pinholes, and two layers (minimum) of paper were required to cover the imperfections. Paper-dielectric capacitors increased in capacitance over several years.

Sometimes the increase measured up to 10%. This probably was the reason so many of the horizontal stabilizing circuits in old RCA TV receivers caused double -triggering.

Plastic film has replaced paper in capacitors.

Plastic-dielectric capacitors

All of the newer plastics used in wound capacitors now are superior to paper. However, the various characteristics vary considerably be tween these different plastics. Some of these important differences will be discussed.

Polyester

Polyester probably is the most common dielectric for present-day capacitors. Polyester can withstand relatively high voltages without shorting (has high dielectric strength), and can be used in most circuits up to an ambient tempera ture of 150 C (302 F) with only nominal drift of characteristics.

Mylar is one brand of polyester.

Polycarbonate

Polycarbonate film retains the good physical properties of polyester while offering improved dielectric absorption, dissipation factor, temperature coefficient and insulation resistance. Polycarbonate approaches the desirable specs of polystyrene, but allows smaller packages and operation at higher temperatures. In short, it's an excellent compromise.

Polystyrene

Polystyrene has very low dielectric absorption and a moderate linear temperature coefficient. The only drawback is the low melting point of 90 C (194 F) which permits operation only up to 185 F.

Polypropylene One of the newest capacitor films is polypropylene, which has excel lent specs that are second only to polystyrene, but without the low-temperature limitation. Polypropylene is rated for use up to 105 C.

Others

Two new capacitor films are poly-sulfone for temperatures up to 150 C and Kapton (trademark of Dupont) for operation up to 200 C.

These are found rarely on the replacement market, although they have good specs.

Metallized dielectrics

A metallic layer is deposited by an evaporative process on a dielectric film to form the capacitor plates, replacing the usual metal foil. This technique has been used on polycarbonate, polyester, poly styrene, polypropylene and perhaps others.

In other words, any of the plastic films can be metallized.

All electrical specs are nearly the same as for the non-metallized films, but the metallized versions can be made smaller, lighter and self -healing.

Probably the benefits from self-healing are the most important to technicians. When the dielectric of a paper capacitor is ruptured by excessive voltage, the paper chars, becomes carbon, and shorts the capacitor. However, in a metallized capacitor, the current from a short circuit burns away the metal film faster than the paper can char.

Thus, the short is repaired.

There are a couple of limitations.

The metallized layers are very thin.

Therefore, this might present a limitation where huge currents are required. Also, the self-healing action probably could not happen in low -voltage or current -limited circuits. Power of the stored field and the external power together must be sufficient to burn away the metallized layer at the puncture, other wise the short continues.

Mica dielectrics

Ruby mica is an excellent dielectric. It has very low loss, moderate "K" factor, and has a temperature coefficient similar to NPO (little change from temperature variations). However, mica breaks when folded, which causes them to be larger than ceramic types and limits the possible shapes. "Silver" mica capacitors contain mica that is treated with silver which acts as the metal plate. Both types of mica capacitors are suitable where a replacement needs low loss, high Q and little frequency drift. Many of the older TV receivers used mica coupling capacitors in sweep oscillators and the oscillators often drifted after unsuitable replacements were installed.

--------- Wound plastic-film types of capacitors have the wire leads at

the center of both ends or from one side (as shown). (Courtesy of Seacor.)

Ceramic capacitors

Selecting the proper type of ceramic capacitor for a precise application must be made with more care than for other capacitors.

An enormous spread of characteristics is found with ceramics. Ceramic capacitors are extremely useful, but you must select them with discrimination.

There are only four general types of ceramic capacitors, although probably hundreds of minor variations exist. A higher dielectric constant (K) enables a capacitor to store more power in the same space. Or the same power can be stored in a smaller capacitor. However, the higher K types are much more unstable to tempera ture, frequency, voltage and rate of aging.

COG/NPO type BP

For stability below 10 MHz, the COG/NPO type BP is recognized as an industry standard. There are no aging effects, and the temperature coefficient is around 30 PPM per degree centigrade. Usually this type has leads. NPO stands for negative-positive -zero, which means the capacitance drift from temperature is almost zero.

COG/NPO type BN

This type is similar to type BP, but comes in chip form only (without leads) and is recommended for use above 10 MHz.

X7R type BR

Probably more of this type is used than any other. Capacitor physical sizes are much smaller than for those with equal NPO values. These are general application (GA) types having an approximate temperature coefficient of ±5% between -40 C to +100 C, a decrease of 10% in capacitance at 50% of rated voltage, and an increase of capacitance with AC voltages. Aging is about -4% after 10,000 hours, and the dissipation factor is between 2% and 3%.

Z5U type GU

This type has about four times the storage capacity of X7R type BR, but it's much more unstable.

For example, the temperature coefficient is about 15% between +10 C and +40 C, but it drops rapidly above +40 C to -60% at about +85 C. A dissipation factor of 3.5%, aging rate of 5% per hour decade, and a 40% capacitance loss at 50% of rated voltage are all higher than other types.

However, these Z5U type GU capacitors are intended for non critical uses such as bypasses or decouplers. Often the capacitance spec is -20% to +80%. Some are specified at a guaranteed minimum value (GMV) so they will not have less than the rated capacitance at room temperature, although the capacitance can be 100% greater than the rating.

If you have ever tried to use this type in oscillators or tuned circuits, probably the results were drifting frequency and low amplitude. How ever, these capacitors are economical and very small, and thus are extremely useful when you know their limitations.

------ With one style of construction, alternate layers of foil and

dielectric are rolled into a tubular shape with the foil extending from the

sides for soldering to the lead wires. The cut-away view shows the final locations.

(Courtesy of TRW.)

Temperature-compensating ceramics

Most RF and IF transformers and coils have a positive tempera ture coefficient. That is, an increase of temperature increases the inductance which in tuned circuits de creases the frequency. One solution for this kind of drift is a tuning capacitor having a negative coefficient that slopes gradually without peaks or valleys.

These temperature-compensating ceramic capacitors are available in many different ratings from N030 to N5600. A popular value is N750, which means the capacitor will decrease 750 parts-per-million (PPM) for each degree centigrade of temperature rise. This translates to -1.5% change for an increase of 20 C.

Filter capacitors

Filter capacitors are available not only in the old favorite aluminum oxide, but now also in tantalum.

The dielectric constant of tantalum is higher than for aluminum; therefore, tantalum filters are smaller for the same capacitance.

Tantalum does not deform when idle, so the shelf life is longer, and the capacitors don't change characteristics as much as aluminum electrolytics do.

Capacitor specifications

Several performance characteristics are important when determining the suitability of a capacitor. These will be described briefly.

Capacity The basic unit of capacitance is the farad, but this is too large for use in conventional electronic circuits. Our basic unit is the micro-farad (one millionth of a farad), which is divided further into nano-farads (one thousandth of a micro-farad) and a picofarad (one millionth of a microfarad). Nanofarads are not used often in service literature, but they are used often by engineers.

Here are the most common con versions from one unit to another:

To change microfarads to nano-farads, move the decimal 3 places to the right.

To change microfarads to picofarads, move the decimal 6 places to the right.

To change nanofarads to picofarads, move the decimal 3 places to the right.

To change nanofarads to micro-farads, move the decimal 3 places to the left.

To change picofarads to nanofarads, move the decimal 3 places to the left.

To change picofarads to micro-farads, move the decimal 6 places to the left.

Of course, you must add zeros to fill any spaces left by moving the decimal. For example, .001 micro-farads equals 1000 picofarads, and 47 picofarads equals .047 nanofarads or .000047 microfarads.

Many capacitors are color coded with the capacitance; however, stripes or dots for tolerance and voltage are added in so many ways that the situation is confusing.

Perhaps you should ask your local distributor about a code sheet for the brand he sells to you.

Tolerance

Usually, the permissible deviation from marked values is expressed as a ± percentage. However, this is for 20 to 25 C, and you will have to apply any change because of other temperatures.

In some circuits, the capacitance is critical. The schematic should indicate that indirectly by stating the percentage required.

Insulation resistance

As the name implies, insulation resistance (dielectric strength) is the ohmmeter reading after the capacitor has stopped charging. Some tests are made at 500 V that's applied for two minutes. Except possibly for some inexpensive ceramic capacitors, insulation resistance is no problem with new capacitors. Film capacitors, for example, often are rated at 25,000 M-Ohm.

----- These are a few of the capacitor types, (Courtesy of Seacor.)

Capacitive reactance

Capacitive reactance is the ability of a capacitor to function as though it is a resistor whose resistance changes with the frequency. It is expressed in ohms, and the "resistance" decreases as the frequency increases. The other capacitor article in this issue gives an explanation of capacitive reactance.

Equivalent series resistance

All capacitor losses (which de grade the performance as though a fixed resistor is placed in series with a perfect capacitor) are lumped under the term equivalent series resistance (ESR).

Some of these losses include dielectric current leakage, corona and dielectric absorption; or resistances in capacitor plates, leads and joints. Formerly, ESR and the dissipation factor were included in the obsolete term power factor.

Dissipation factor and "Q"

Capacitor "Q" is defined as the ratio of capacitive reactance to the equivalent series resistance. Higher "Q" ratings are desirable.

Dissipation factor (DF) is the mathematical reciprocal of "Q".

Therefore, it should be as low as possible. Polypropylene has the lowest DF of the films, followed in order by polystyrene, polysulfone, polycarbonate and polyester.

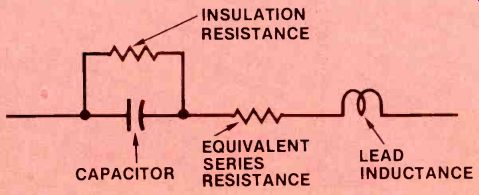

Total schematic

Practical capacitors are diagrammed as a perfect capacitor in series with an inductance and a low-value resistor. In addition, an other higher-value resistor is connected in parallel with the series components. This is illustrated in one of the figures.

-------- Metal-can filter capacitors have screw terminals for computer

use (as shown) or with twist -lock mounting and solder lugs) (Courtesy of

Sangamo.)

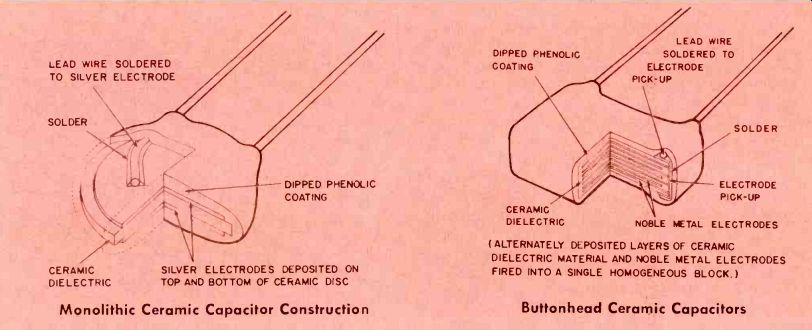

-------- Most ceramic capacitors are manufactured in these two kinds of

construction. Some resemble resistors (not shown). (Courtesy of Sprague.)

Dielectric absorption

If you ever have discharged a large picture tube, and then later received a severe shock from the anode button, you have had practical experience with dielectric absorption (DA).

The effect occurs in all capacitors having a solid dielectric, although it varies considerably according to the material. Non -polar materials do not permit instantaneous rotation and alignment of the atomic electrons. There is a time lag during both charge and discharge modes.

Contaminants or impregnants in the dielectric material also vary the intensity of the effect.

At the factory level, DA is measured by giving the capacitor the rated charge, discharging it through a 5 -ohm resistor for 10 seconds, waiting for 60 seconds, and then measuring the voltage by using an electrometer.

These are typical dielectric absorption percentages of some materials:

Tantalum pentoxide 8%

Polyester (Mylar) 0.30%

Polysulfone 0.15%

Polycarbonate 0.15%

Polystyrene 0.05%

Polypropylene 0.02%

Dielectric constant

Dielectric constant (K) is a measure of the additional charge a capacitor can handle when other dielectrics are substituted for a vacuum. (Actually, dielectric constant is misleading, since there is some variability. Authorities use the term permittivity instead.) Here are the approximate K values of a few substances:

Vacuum Air Paper Glass Mica Polyester Kraft paper

1.0000 1.0006 2.1-6.0 4.8-8.0 5.4-8.7 2.8-3.1 about 4

Aluminum oxide about 7 Tantalum oxide about 11 Ceramic NPO 25-100 Ceramic X7R 300-1800 Ceramic Z5U 2500-15,000 (Other sources give slightly different figures.) For example, a capacitor using aluminum oxide can store an electrical charge seven times greater than can a similar capacitor with a vacuum dielectric.

Probably the most important reason why materials of higher "K" are not used for all dielectrics (thus reducing the physical size for the same capacitance) is that the lower "K" dielectrics are more stable. However, don't compare polyester against a NPO ceramic; they are in different categories.

Temperature coefficient

Temperature coefficient describes the changes of capacitance that occur at different capacitor temperatures. It is expressed either as a percentage change or in the number of parts-per-million (PPM).

None of the plastic films drifts tremendously, but none is without drift.

Polysulfone probably has the least change from temperatures between 32 F and 212 F (however, hermetical sealing is recommended to keep out moisture), followed in descending order by polycarbonate, polystyrene, polypropylene and polyester.

It is difficult to be precise in these ratings, because metalizing makes some change and different physical features also have an effect on the TC.

Capacitance changes from applied voltage

Some capacitors increase capacitance when supplied with ac voltages, and decrease capacitance with dc voltages. This appears to be serious only with certain "high K" (low "Q") ceramic capacitors. Therefore, you need not be concerned when using other types.

Remember, the "high K" types should not be used where capacitance is critical.

----- Real-world capacitors have several kinds of loss problems. Insulation

resistance decreases with tempera ture, causing additional leakage. The equivalent

series resistance is the sum of all losses that affect the capacitor operation

as though a resistor is added in series. A small amount of inductance always

is present. This is one reason every capacitor has a self -resonant frequency

where the impedance is minimum.

Ordering by specification

These capacitor facts should have explained why a ceramic capacitor of correct marked value (but un known type) worked so poorly when used in a vertical multivibrator, for example. Best results can be achieved only when the replacement capacitor has proper specs for the circuit.

Capacitors used in multivibrator or other time-constant oscillators and sample-and-hold circuits should be a type with low dielectric absorption. All oscillator capacitors must be stable with temperature changes, while some need the negative-temperature types to cancel drift introduced by other components.

Pulse circuits

Quite often, you will see manufacturer's admonitions to use only their replacement capacitor. One of those critical areas is the SCR-sweep circuits. We have heard the horror stories about ordinary capacitors that heated and then shorted, although they were operated well within their rated voltages.

There are two warnings here. One is that the capacitor must be designed for high-current operation (low dissipation), low dielectric absorption and freedom from internal corona.

Metallized capacitors might not carry the extreme currents. From the listings we have made here, polypropylene and polycarbonate should be first and second choices because of the low di-electrical absorption and low dissipation.

Curie point

Ceramic capacitors are made from a powder which is subjected to heat and pressure in a mold. At first, the capacitance drops severely over several days or weeks. After this initial variation (which de creases the capacitance only to the rated value), the capacitance slowly decreases over a period of years.

However, heating a X7R or Z5U type capacitor to the Curie temperature (of 125 C or above) restarts the capacitor at the original excessive capacitance, which is followed by fast aging before stability is restored.

------ A typical temperature characteristic curve for polyester dielectric

is shown. Other plastic film capacitors have a flatter curve. (Courtesy of

TRW.)

Therefore, avoid excessive heat when you solder these two types of capacitors. Use cooling spray on the capacitor body immediately before soldering to prevent the capacitor from becoming too hot.

Beware of unknowns

Do you have a large quantity of ceramic and wound capacitors that you have kept for 10 to 20 years? Chances are good that you don't know what type they are. To avoid call-backs and other penalties of using inferior components, perhaps you should throw them all out and stock new types that are best ,for replacements.

Substitute a higher rating

A helpful general rule is to install a replacement capacitor of higher ratings than those of the original that failed.

For example, a wound tubular 200-V capacitor could be replaced by a 400-V or 600-V type. Some of the new ones are smaller physically than are the old paper versions. If you must substitute for a mica, use only a NPO ceramic.

Also, a polycarbonate can be substituted for a paper or polyester.

Don't knowingly stock any Z5U ceramics. Use the better X7R instead. The smaller total stock will be more valuable than the lower prices on those few Z5U ceramics that are really needed.

Also see: Capacitors: Components of many faces